|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

Section IV. ASSEMBLY

available for use during assembly. Table II lists

28. GENERAL

the lubricant, the part to which it is to be ap-

lied, and the method of application. Make cer-

a. The assembly procedures are covered in

the following paragraphs of this section. Ref-

tain that these instructions are performed dur-

ing assembly.

erence should be made during assembly and

installation to the exploded views in the disas-

sembly section for the proper relationship and

position of components.

Note. The key letters shown below in paren-

b. Apply thread sealer to pole shoe screws,

theses refer to figure 19 except where other-

wise indicated.

before assembly.

c . An oil hole must be drilled in the lever

a. Install terminal stud insulator bushing (D)

housing, commutator end plate, and drive hous-

on field coil terminal stud and position field coil

ing sleeve bearing after installation. If any

(C) in frame (A). Install insulator (B) and two

sleeve bearings are replaced, they must be

insulations (G) between frame and field coils.

reamed or burnished to the dimensions speci-

fied in the "Sizes and fits of new parts" column

b. Position each of four pole shoes (E), in

of the wear limits (par. 41e) after installation

turn, on coil inside frame align mating holes and

in housings, end plate, or clutch sleeve.

secure each pole shoe with two pole shoe screws

(refer to step 2, fig. 18). Coat threads of pole

29. LUBRICATION

shoe screws with a suitable thread sealer be-

fore installation.

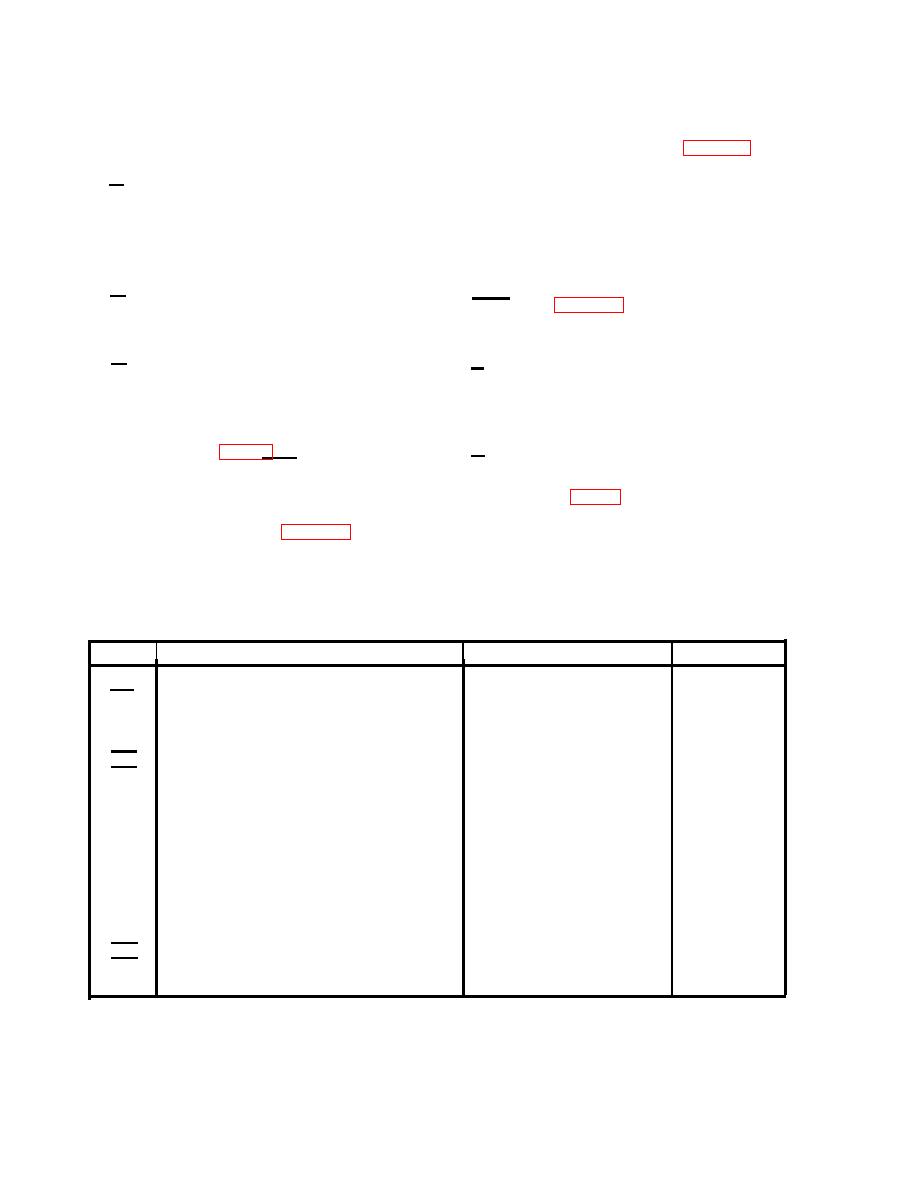

The lubricants listed in Table II should be

Instructions

Lubricant

Point of lubrication

Par. ref.

Coat splines.

GREASE, AIRCRAFT

Clutch and armature splines.

32a

and INSTRUMENT (GL).

and

35--

c

Soak wick and

LUBRICATING OIL,

Felt wicks and felt plugs.

32b,

plugs until

INTERNAL COMBUS-

33b,

saturated.

TION ENGINE (OE 10)

and

34

Lightly coat

LUBRICATING OIL,

Clutch sprags.

32--

a

sprags.

INTERNAL COMBUS-

TION ENGINE (OE 10)

Coat surface.

Clutch shell (shift lever contact surface). GREASE, AIRCRAFT

35--

b

and INSTRUMENT (GL).

Lightly coat

GREASE, GENERAL

Preformed packings and gaskets.

32b,

preformed

PURPOSE, medium

32c,

packings and

grade.

and

gaskets.

35--

c

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |