|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

(2) Inspect the yoke for wear in the

(4) Inspect armature shaft aline-

shaft hole and wear on the slider

ment and commutator for ec-

blocks.

Replace the yoke if

centricity to shaft with a lathe

or "V" blocks and a dial indi-

wear exists.

cator (fig. 31). Check armature

27. R e p a i r

shaft for true alinement. If

shaft run out exceeds 0.005-

a.

inch, armature must be re-

General.

The following subpara-

If commutator eccen-

graphs cover only those parts wherein a

placed.

repair operation will return the damaged

exceeds 0.003-inch,

tricity

commutator of armature shaft

part to serviceable condition. Parts not

must be refinished provided it

detailed herein must be replaced when they

fail to pass the required inspection (par.

will not be cut below limits

specified in repair and rebuild

26).

If com-

standards (par. 40).

b. Pinion Housing. Minor burs or dam-

mutator requires cutting below

age on the mating ,surfaces of the pinion

limits specified, replace arm-

housing can be removed or cleaned up with

ature.

a fine mill file.

Head and Bushing Assembly.

h.

Inspect the commutator end head

(1)

for cracks, distortion, and

burs. Replace if damaged.

Inspect the head bushing-type

(2)

bearing for score marks and wear

patterns. Check bearing against

limits specified in repair and

rebuild standards (par. 40) and

replace using a 0.750-inch ar-

bor if worn beyond limits.

If head bushing-type bearing is

(3)

removed, check diameter of bear-

ing bore in commutator end head

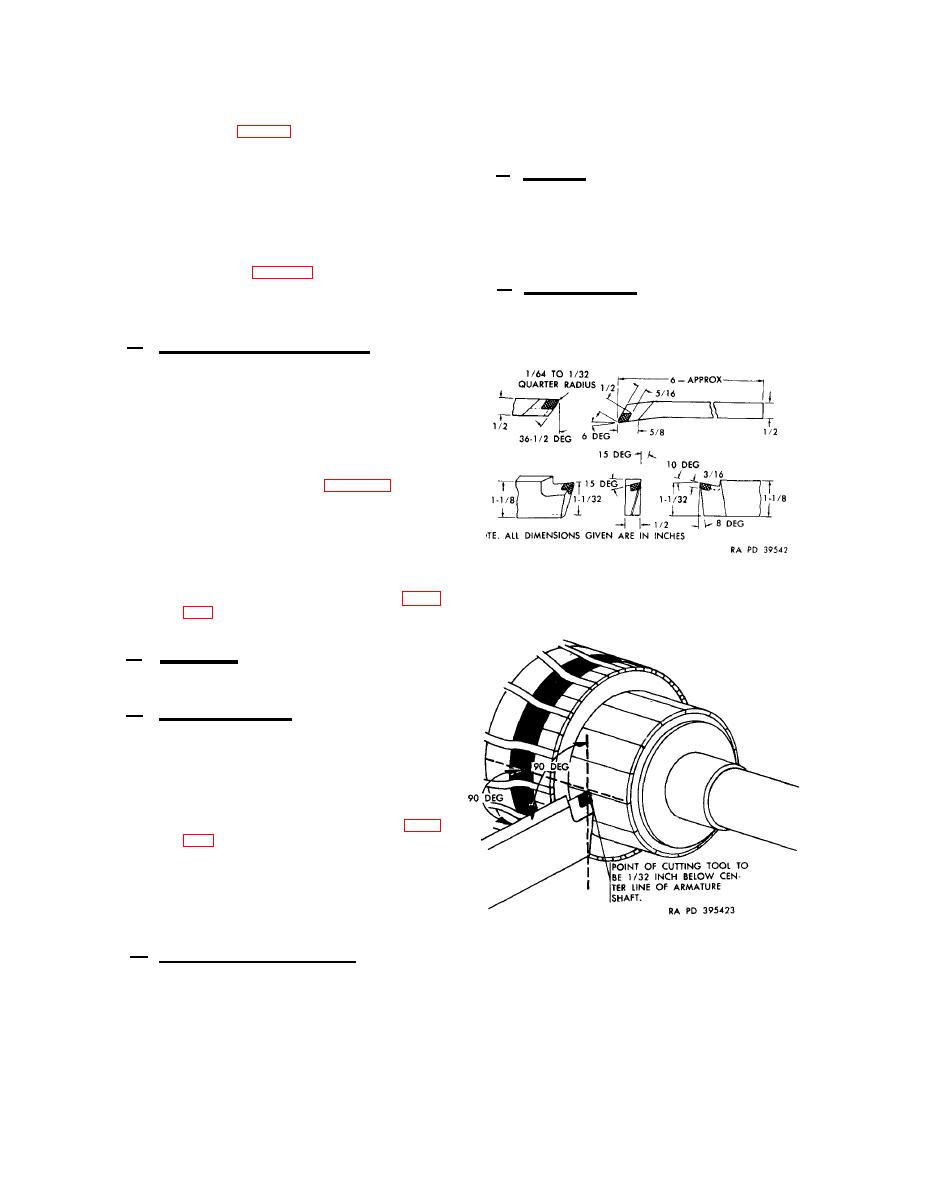

Figure 32. Cutting tool

against limits specified in re-

sharpening dimensions.

pair and rebuild standards (par.

not within these limits.

i. End Cover. Inspect the end cover

for dents, cracks, and distortion. Replace

if damaged.

i. Switch Assembly.

(1) Inspect the switch body for

cracks, distortion, and burs.

Replace if damaged.

(2) Check plunger rod return spring

against limits specified in re-

pair and rebuild standards (par.

return

spring if it is not within these

limits.

(3) Inspect the switch blade hous-

ing for cracks, distortion, and

burs. Replace if damaged.

Figure 33. Proper position of

cutting tool.

k.

Shifting Lever and Yoke.

(1) Inspect the shifting lever for

wear on the shaft and burs in

Replace

the packing groove.

the lever if worn or damaged.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |