|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9- 2920- 232- 34&P / TO 38X14- 2- 32

-

-

-

- -

REPAIR OF COMPONENT PARTS - CONTINUED

-

0009 00

c.

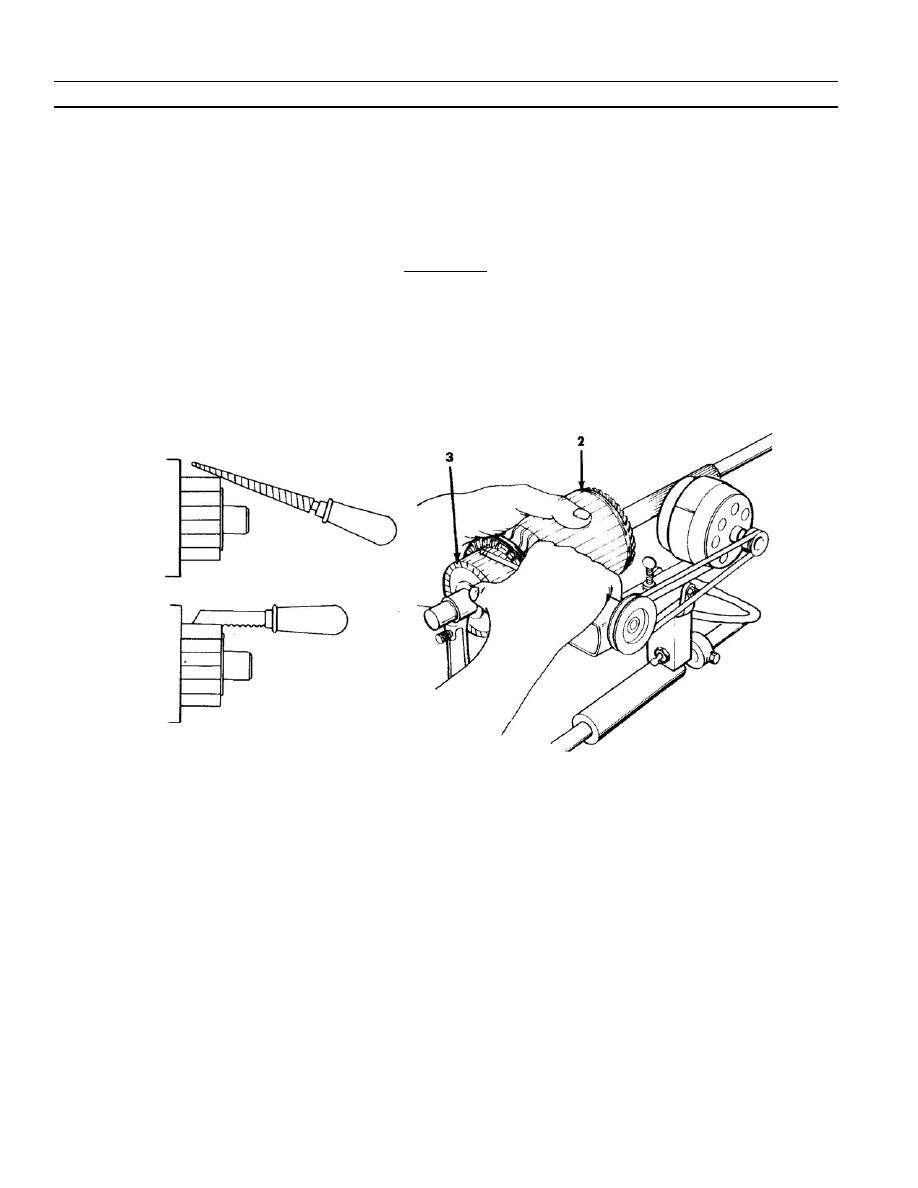

Set lathe to turn armature (2) at 800 rpm.

d. Make only light cuts, no more than 0.005 inch on each pass, until entire surface of all commutator bars (3) is

involved.

e. Make one final cut at no more than 0.002 inch deep.

f.

Check diameter of commutator (3). The commutator diameter on armature should be between 2.3080 to

2.3180. If less than minimum turned diameter of 2.1930 inch, armature (2) must be replaced.

CAUTION

Use care when undercutting so that no metal is removed from sides of segments and no mica

is left standing against side of a segment.

g. If turned diameter of commutator (3) is no less than minimum limit, undercut mica to a depth of 0.025 to 0.032

inch below commutator surface.

h. Start groove in mica with a 3--cornered file.

i.

Undercut mica with a hacksaw blade.

0009 00- 2

-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |