|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9- 2920- 224- 34&P

-

-

-

WATERPROOF TESTING OF THE GENERATOR - CONTINUED

-

0012 00

2. Test Procedure.

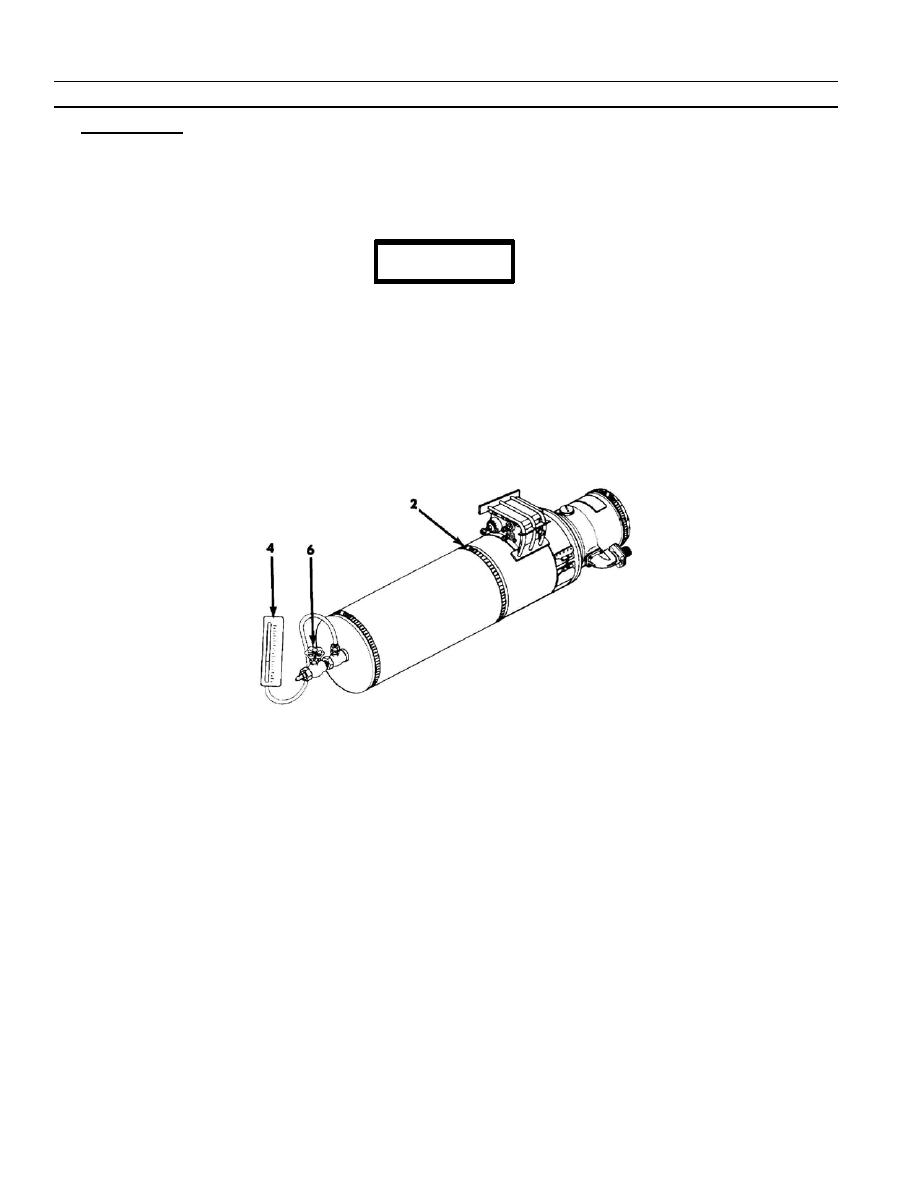

a. Open shutoff valve (6) to increase air pressure in outlet closure (2) (and in generator) to 6 in. Hg. (2.95 psi).

b. Close shutoff valve (6) and start timing at an interval of 2 1/2 minutes.

c.

At end of timed interval, pressure indicated on gage (4) shall be at least 2 in. Hg. (0.98 psi). If pressure is less

than 2 in. Hg (0.98 psi), excessive leakage is indicated.

CAUTION

Do not allow water to enter generator. Maintain positive

pressure to test setup whenever generator is lowered into

water.

d. If leakage is indicated, open valve (6) to restore 6 in. Hg (2.95 psi) and submerge generator with air--tight

closures in water dip tank. Note source(s) of air bubbles.

e. If source of leakage is at air--tight closures, this leakage must be stopped to obtain true leakage rate for

generator. Repeat steps a through c after leakage at air--tight closure has been stopped.

f.

When only source(s) of bubbles are on generator, remove air pressure and apply sealant externally at source

location(s). Allow sealant to set, then retest (steps a through c).

END OF TASK

0012 00- 2

-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |