|

|||

|

|

|||

|

Page Title:

Basic Generator Assembly-continued |

|

||

| ||||||||||

|

|

TM 9- 2920- 224- 34&P

-

-

-

DISASSEMBLY OF THE GENERATOR ASSEMBLY - CONTINUED

-

0008 00

r.

Check armature shaft and commutator. Replace if armature shaft bearing diameter exceeds 1.1810 to 1.1813

inch at commutator end or at drive end. The fit of the shaft in the bearing shall be 0.0006 inch (tight fit) to

0.0001 inch (loose fit).

WARNING

Do not use test voltage greater than 220 V, and use care

when testing insulation resistance. Bodily injury can result

from contact with test voltage.

s.

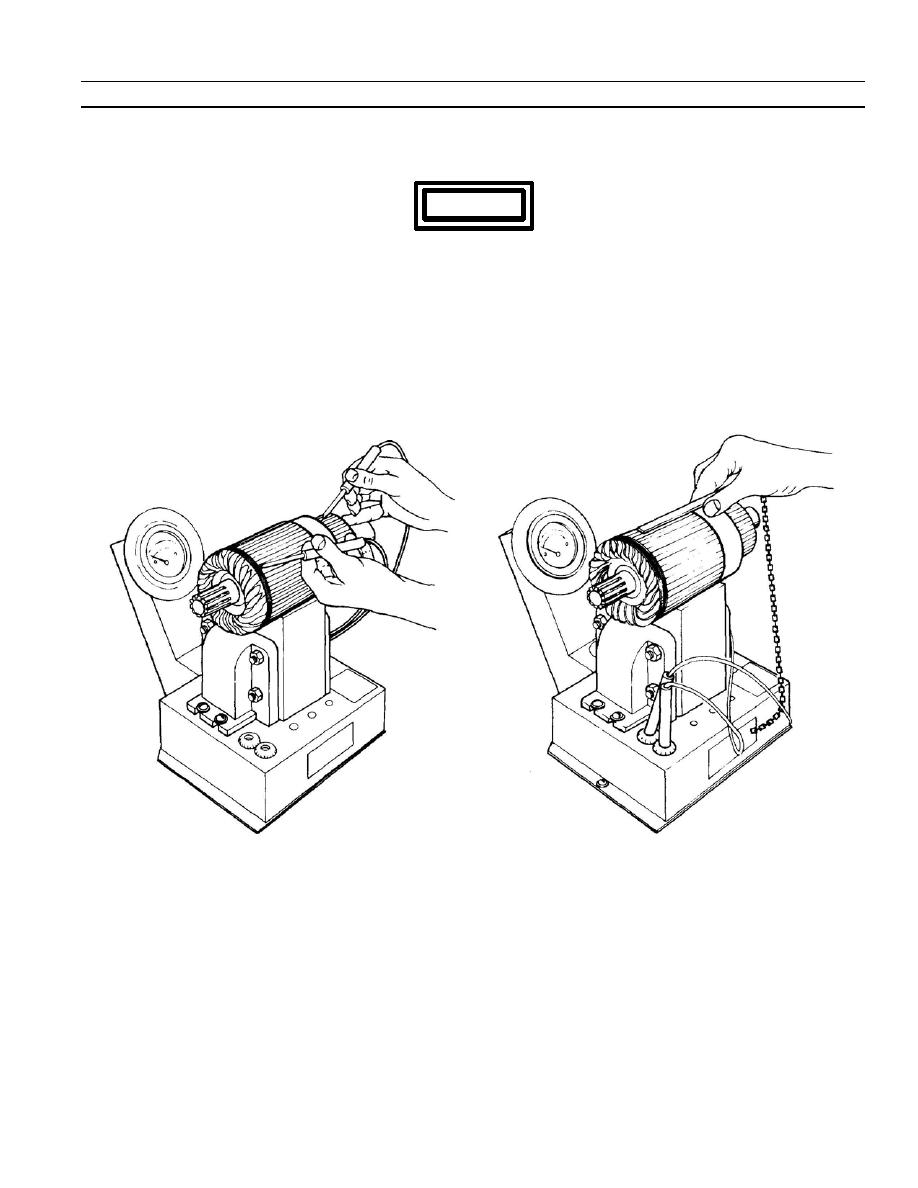

Inspect armature for grounds with an insulation test circuit (110 or 120 V in series with 50--watt lamp) by

touching one of the test probes to armature core and the other probe to one of the commutator bars. If test

light glows, the armature is grounded and must be replaced.

t.

Inspect armature for short circuits using a growler fixture. Place the armature in growler. Hold a thin strip of

steel, such as a hacksaw blade on armature. While holding the steel strip in position, rotate armature slowly in

growler. A short circuit will cause the strip to vibrate. If a short circuit is found, replace armature.

0008 00- 9

-

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |