|

|||

|

|

|||

|

Page Title:

Hydraulic Head Port Closing Test. |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

f. Connect outlet of the nozzle tester to the im-

provised adapter using a high pressure hose.

g. Install locally fabricated U tube in the No. 1

hydraulic head outlet. Position a plastic container

under the open end of the U tube to collect test oil

(which will be returned to the tester reservoir) (fig. 3-

164).

h. Remove timing device cover and timing

window cover, or fuel shutoff housing.

3-53. Hydraulic Head Port Closing Test. a. Secure

the throttle lever in the full fuel position with a

spring or other suitable device (fig. 3-163).

and delivery valve spring (B). Reinstall delivery

valve screw.

NOTE

Delivery valve is matched to the hydraulic

head. Do not replace or interchange valve.

c. Apply 3-10 psi test oil pressure to the hydraulic

head with the nozzle tester. Loosen the in, pipe

plug in the hydraulic head overflow valve opening to

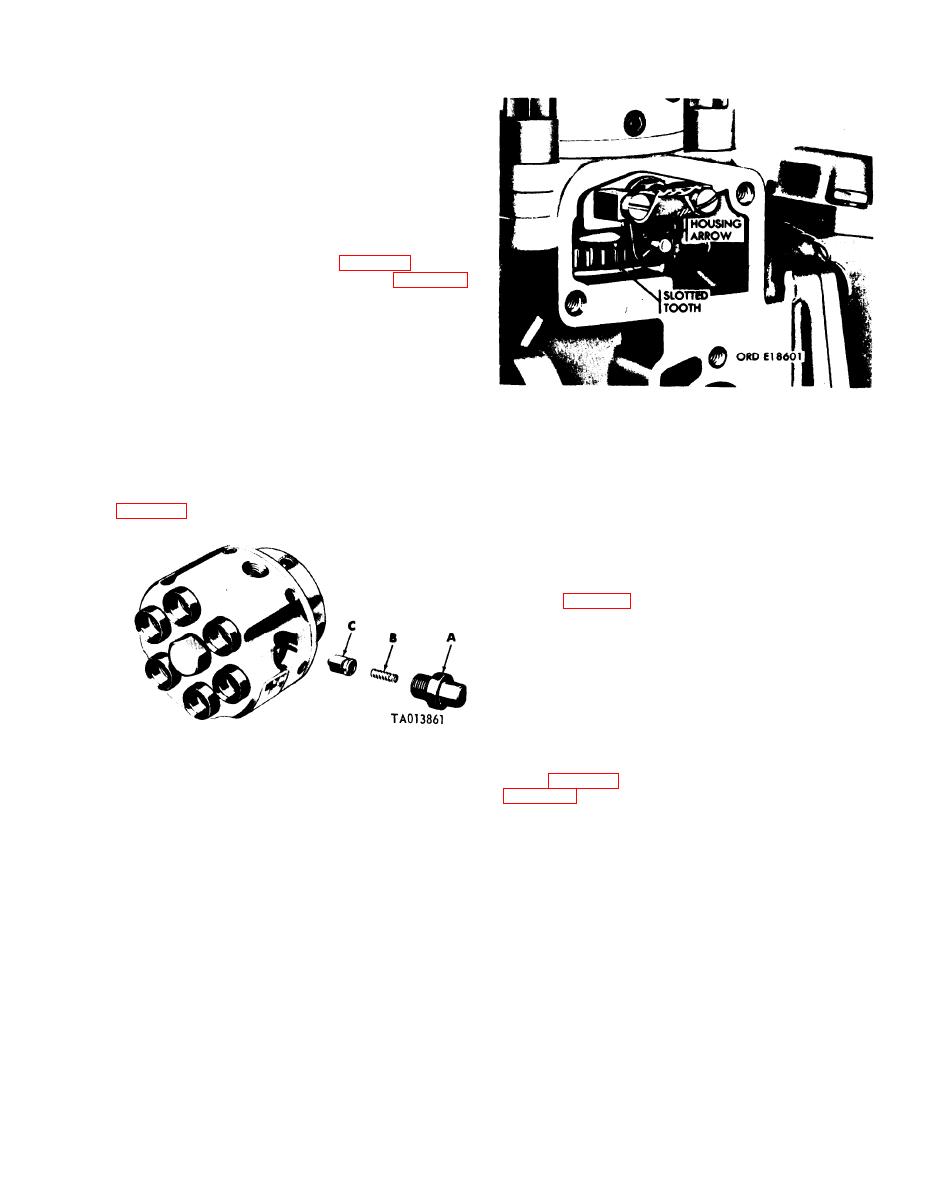

Figure 3-167. Alining slotted tooth with arrow on housing.

bleed air from the head. Tighten plug.

NOTE

d. Rotate the test stand drive coupling clockwise

The scribed mark on the advance unit hub

(as viewed from the drive end) with the test stand

should not be alined with its pointer,

spanner wrench until the slotted, red painted tooth is

e. Slowly continue to rotate the drive hub in a

visible in the timing window on the pump housing

clockwise direction (as viewed from the drive end)

until the test oil begins to form droplets at the end of

the U-tube. Slowly continue to rotate the drive hub

until the test oil flows freely and then diminishes and

stops. This is port closing. The scribed mark on the

advance unit hub should now be alined with the

pointer (fig. 3-168) and the slotted, red painted tooth

in the timing window should be one tooth to the right

of the mark on the pump housing. If the above

specification is not met, the hydraulic head, tappet

assembly and/or camshaft must be replaced. If the

plunger button is damaged, hydraulic head must be

replaced.

f. Install the timing device cover using a new

gasket, and tighten the retaining bolts and lock-

washers fingertight. Install timing window cover or

A Delivery valve screw

fuel shutoff housing. Remove U-tube from hydraulic

B Delivery valve spring

head (fig. 3-164). Remove delivery valve screw (A,

C Fuel delivery valve

Figure 3-166. Installing fuel delivery valve and screw.

3-97

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |