|

|||

|

|

|||

|

Page Title:

Installation of Overflow Valve Assembly |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

NOTE

If the injection pump is to be tested after

assembly, do not tighten the overflow valve

or plastic tubing until the fuel leakage and

timing check as described in paragraphs 3-50

through 3-58 has been performed.

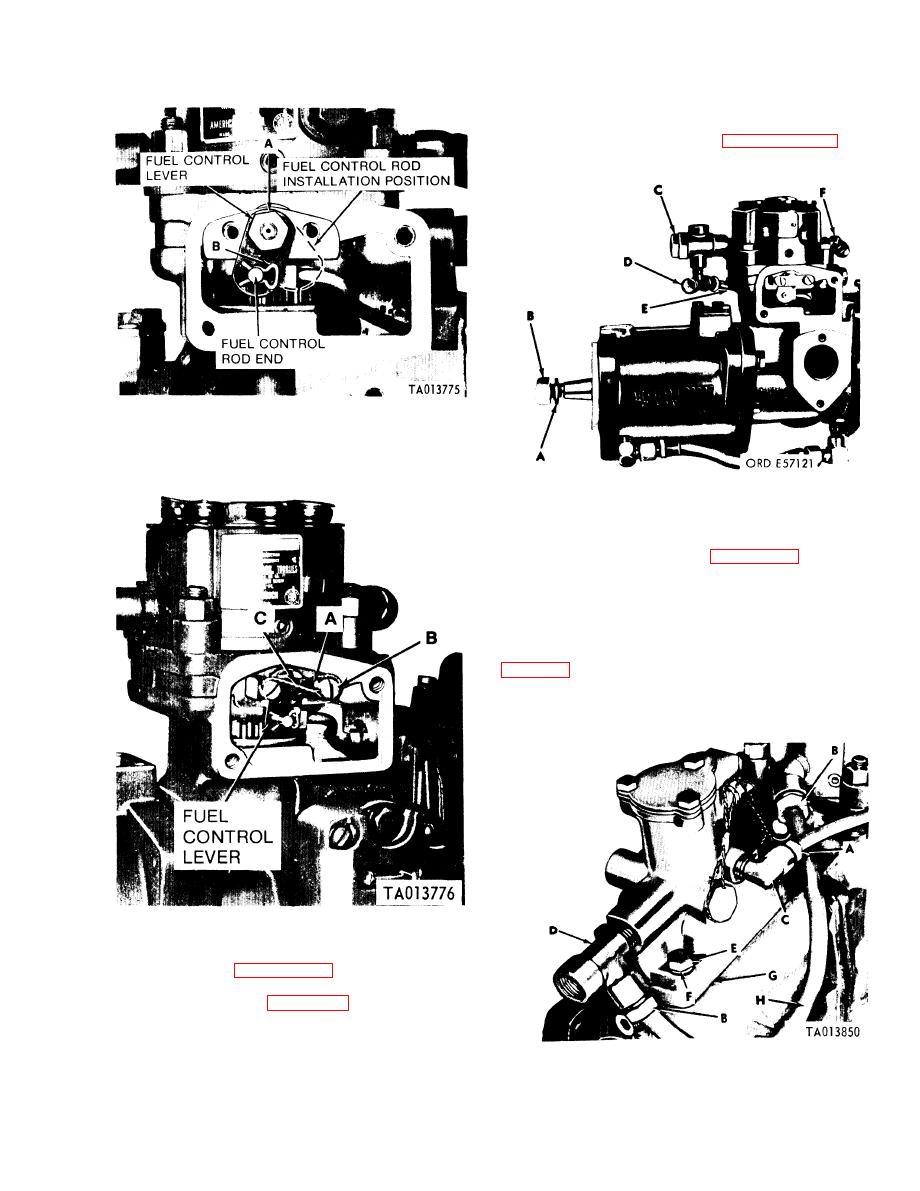

Figure 3-150. Installing fuel control unit assembly on metering

and distributing fuel injection pump.

Figure 3-152. Installing overflow valve assembly

3-46. Installation of Fuel Density Compensator. a.

Installation of Fuel Density Compensator (Code B,

tion a new mounting gasket (G) on governor

housing. Position fuel density compensator on

governor housing and secure with four x 1

capscrews (E) and four inch lockwashers (F).

Torque tighten screws 50-60 inch-pounds. Install

density compensator to overflow valve tubing (E,

tubing (H) to tee (D) and elbow in hydraulic head

(B).

Figure 3-151. Installng control unit retainer.

3-45. Installation of Overflow Valve Assembly. a.

selection of the proper overflow valve assembly.

washer (A) and stet nut (B) on advance unit shaft.

Tighten nut finger tight. Install overflow valve

assembly (C) in position on hydraulic head.

Figure 3-153. Installing fuel density compensator assembly.

3-87

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |