|

|||

|

|

|||

|

Page Title:

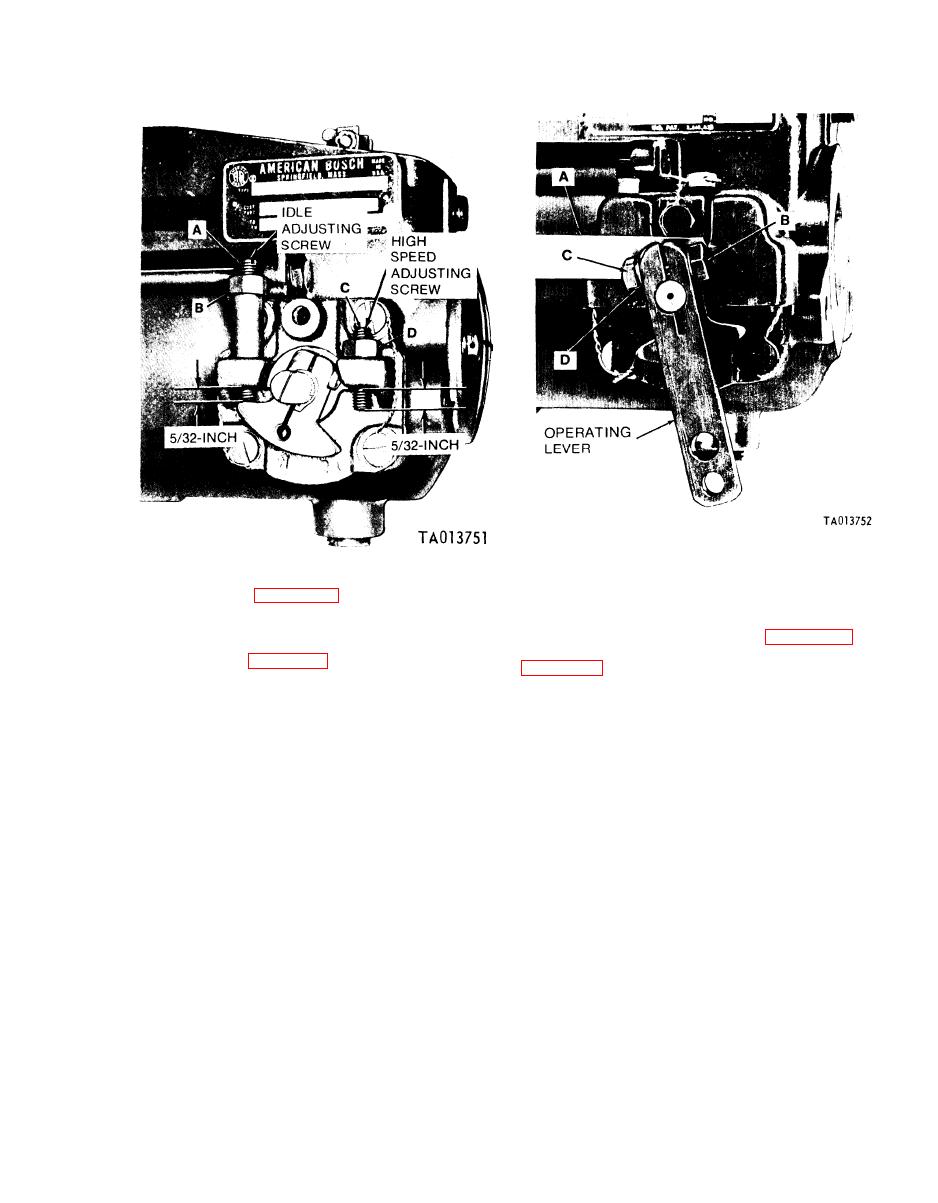

Figure 3-83. Installing high speed and idle adjustment screws. |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

Figure 3-84. Checking operating lever clearance using a feeler gage

Figure 3-83. Installing high speed and idle adjustment screws.

NOTE

(17) Refer to figure 3-59 and install dust cover

Sub-paragraph (19) below applies to code A

(D), lockwasher (C) and machine bolt (B). Torque

pumps only.

tighten dust cover bolt to 50-60 inch-pounds. Do not

(19) Refer to (16) above and figure 3-83 and

install lead seal safety wire at this time.

install idle and high speed adjusting screws. Refer to

(18) Refer to figure 3-84. Insert a feeler gage (A)

to obtain a clearance of 0.002 to 0.004 inch between

piece on this pump. Install screw (A), lockwasher (B)

the operating lever and dust cover. Loosen clamping

and nut (C). Install operating lever assembly in up

screw (B), lockwasher (C), and nut (D). Move lever

position on operating shaft (D) with the split in lever

as necessary to obtain this clearance. Torque tighten

alined with scribe mark on end of operating shaft

nut to 70-75 inch-pounds.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |