|

|||

|

|

|||

|

Page Title:

Repair of Fuel Density Compensator Assemblies |

|

||

| ||||||||||

|

|

TM 9-2910-226-34

density compensator assemblies. Do not

disassemble.

a. Discard original type (2910-017-9776) and retain

other types (2910-907-0665 or 2910-125-3793) for

possible reuse.

b. New compensator assemblies are furnished

calibrated and do not have to be checked for

calibration before installation. If it should be

necessary to check operation of a new or used

compensator, it may be functionally inspected in the

following steps.

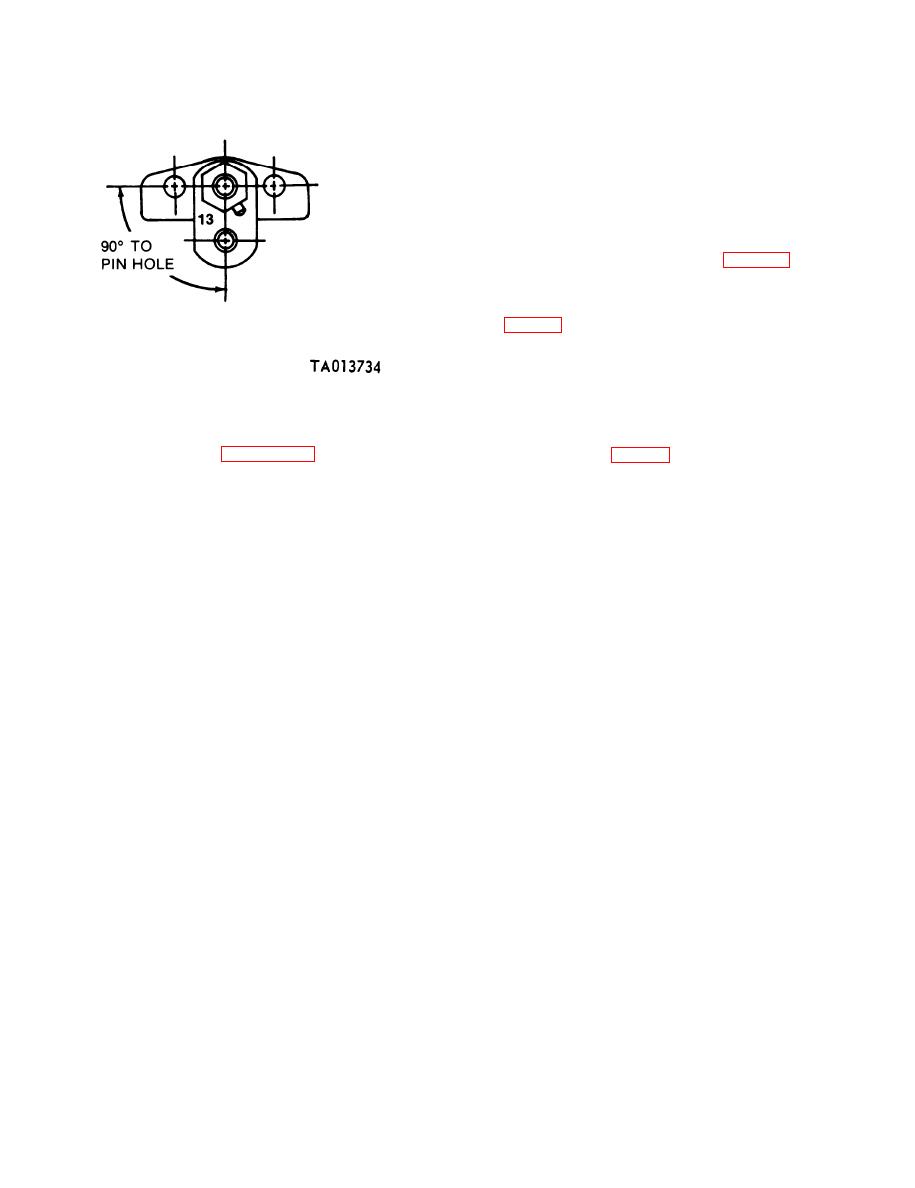

(1) Manually operate stop plate (fig. 3-51)

through full travel. It must have smooth action with

no indication of sticking.

(2) Apply 35-45 psi fuel pressure to compensator

fuel inlet (fig. 3-51); and stop plate must move to the ,

up position.

(3) Manually depress stop plate to full travel.

Note that remaining travel, when pressurized is

0.040 to 0.060-inch. This will cover a fuel range of -

Figure 3-50. Fuel control lever identification (code G pump).

DF-1 and DF-2. If travel is more than 0.060-inch,

(3) Final inspection of the fuel control unit will

replace the compensator.

be accomplished at fuel injection pump calibration

(4) Plug fuel inlet and apply 10 psi fuel pressure

to fuel outlet connection (fig. 3-51) and maintain for

plunger sleeve pin (A). Install new control unit

approximately one minute.

packing (B).

3-24. Repair of Fuel Density Compensator

Assemblies.

NOTE

There are no service or spare parts for fuel

3-36

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |