|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2835-255-34

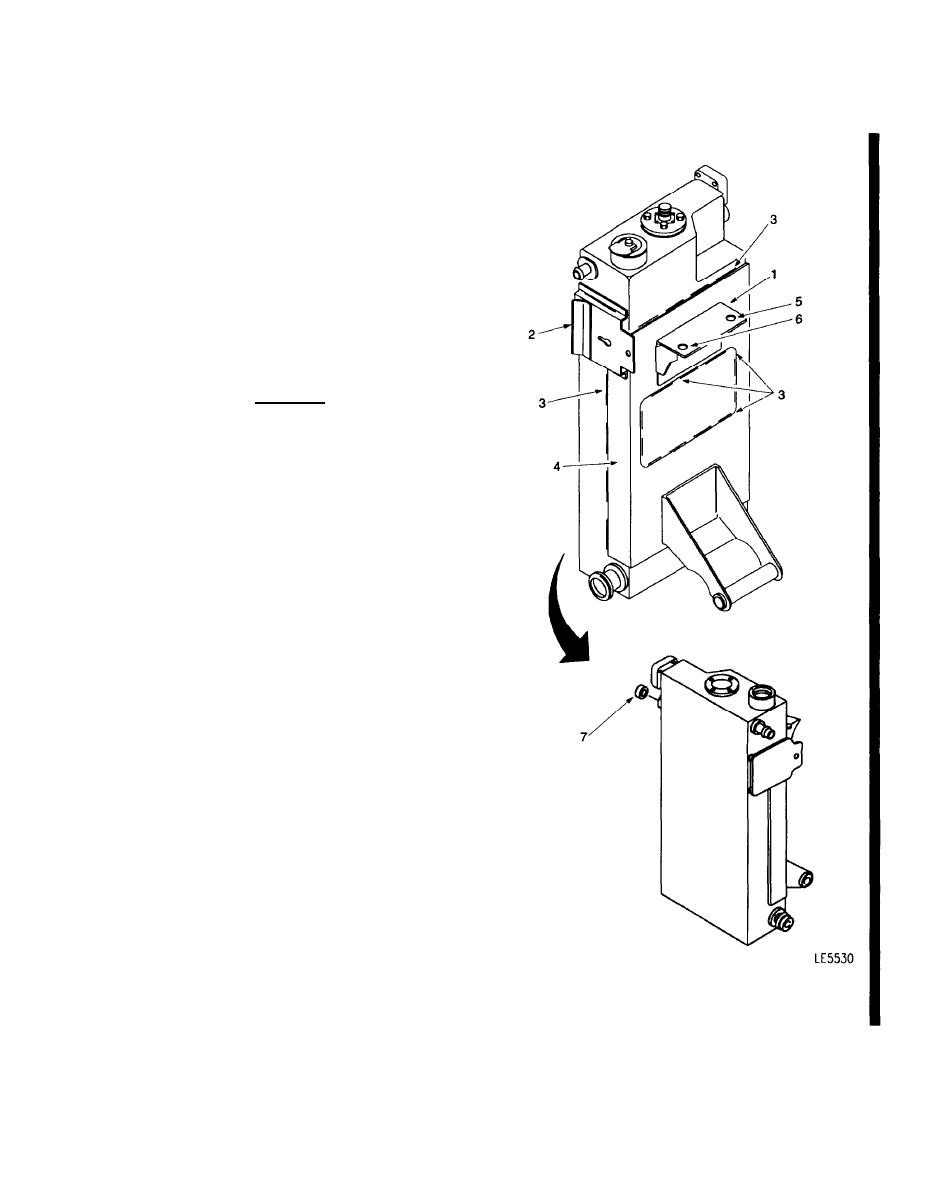

LUBRICATING OIL TANK REPAIR (Sheet 4 of 7)

c.

Visually inspect oil tank support flange (1) for

cracks in fusion welds and parent material.

d.

Visually inspect for broken spot welds at igni-

tion exciter mounting bracket (2).

e.

Visually inspect for cracked fillet welds (3) and

broken or cracked mounting plate (4) and

bracket material.

f.

Visually inspect bushing (7) for damage.

REPAIR:

CAUTION

BEFORE DOING WELD REPAIRS, MAKE

SURE OIL TANK INTERIOR HAS BEEN

THOROUGHLY CLEANED PER STEP 1 TO

REMOVE ANY REMAINING OIL.

1. TIG WELD ANY CRACKED WELDS, OR CRACKS

IN TWO BOLT HOLE AREAS (5, 6) OF SUPPORT

FLANGE (1).

a.

Route as required to remove cracks, raised or

cracked metal.

b.

Wirebrush area(s) to be weld repaired and

clean with cleaning solvent.

c.

Tig weld routed areas using AMS 5680 weld

wire with gas tungsten arc welder (GTAW).

d.

Blend top surface to original flatness and to

remove weld spatter.

e.

Using dye penetrant method, inspect repaired

areas. No cracks allowed.

Go on to Sheet 5

8-7

Change 6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |