|

|||

|

|

|||

|

Page Title:

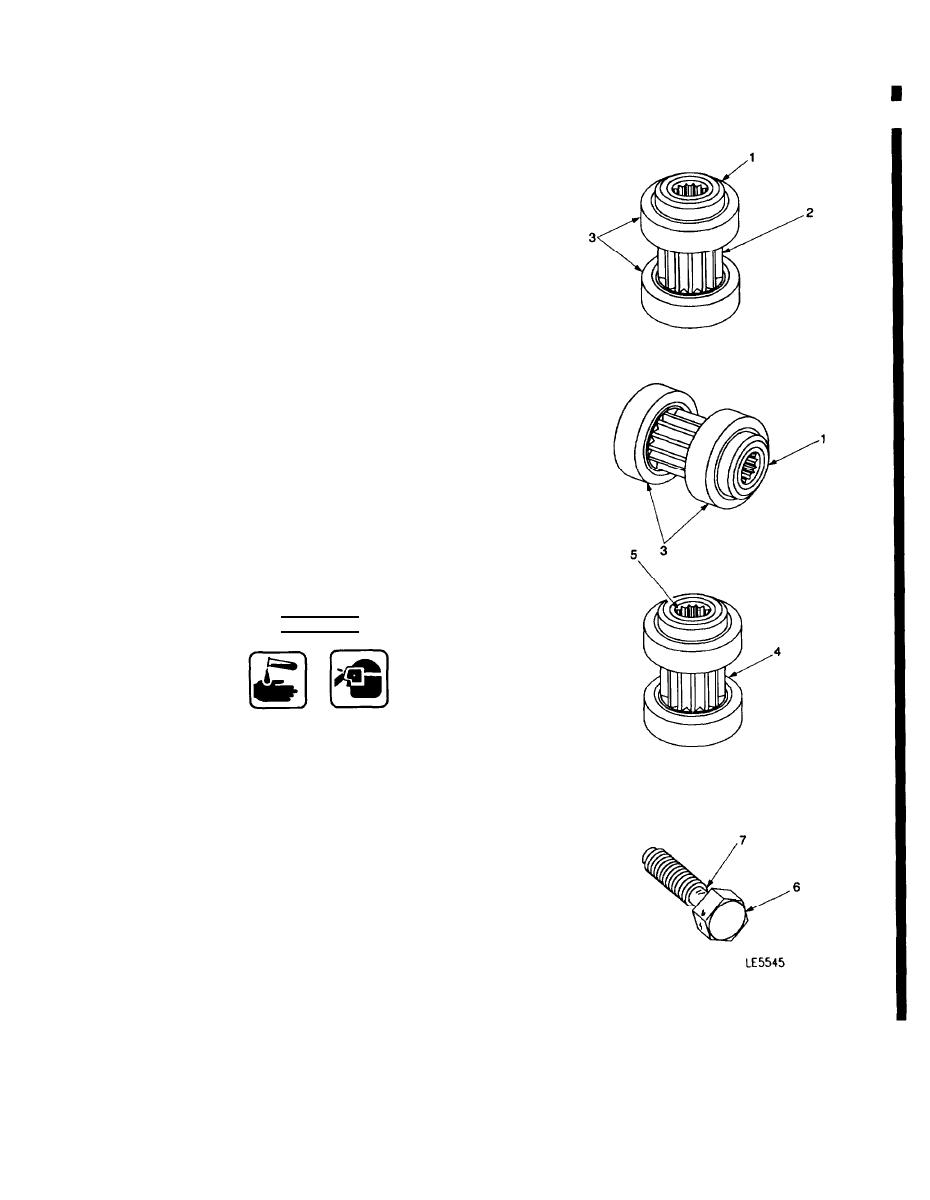

INSPECT SPUR GEARSHAFT ASSEMBLY |

|

||

| ||||||||||

|

|

TM9-2835-255-34

ACCESSORY GEARBOX CLEANING AND REPAIR (Sheet 14 of 40)

5.

INSPECT SPUR GEARSHAFT ASSEMBLY (1).

NOTE

Damage found in steps a. through d. is

not allowed. Replace bearings and spur

gear as required (Ref. pg 7-64).

Look at spur gear (2) and bearings (3) for

a.

cracks, chips or any red-purple, purple or

blue discoloration.

b.

Look at two bearings (3) for rust, broken

parts, pitting, spalling or dirt.

Using four-power magnifying glass, check

c.

gear teeth (4) and accessory drive splines (5)

for wear and corrosion.

d. Visually inspect spring pin inside spur gear-

shaft for cracks or deformation.

lf any damage was found in steps a. through

e.

d., replace bearings spur gear and/or spring

pin as required (Ref. pg 7-64).

WARNING

6.

INSPECT SCAVENGE PUMP NOZZLE (6).

a.

Look at nozzle (6) for damaged threads and

clogged oil jet hole (7).

b.

Replace nozzle (6) if threads are damaged.

c.

Clean out clogged hole (7) with twist drill and

cleaning solvent.

Go on to Sheet 15

7-59

Change 6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |