|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2835-255-34

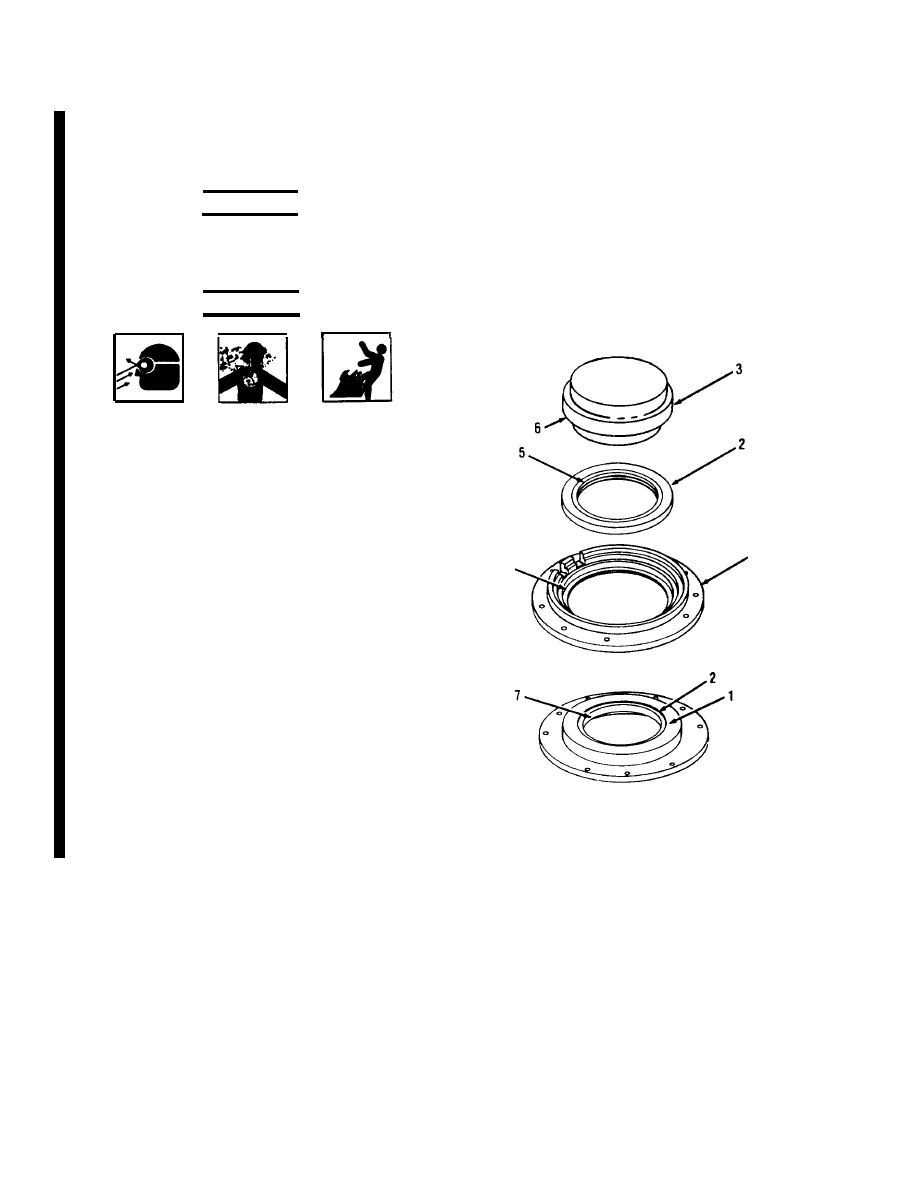

NO. 10 BEARING SEAL REPLACEMENT (Sheet 4 of 6)

INSTALLATION:

WARNING

Use caution when using press. Improper tools, or

tools not properly alined may cause injury to per-

sonnel or damage to parts or equipment.

WARNING

1.

CLEAN OLD SEALANT FROM PLATE (1)

AND INSTALL NEW SEAL (2) IN PLATE

(l). USE REMOVAL AND INSTALLATION

TOOL (3).

Turn plate (1) over and clean old sealant

a.

from seal mating surface (4). Use solvent

1

and rag.

4

Position plate (1), rear side down, on press.

b.

Apply a thin coat of sealant on outside

diameter of seal (2). Position seal (2) on

plate (1) with carbon element lip (5) up.

c.

Press seal (2) in plate (l). Use tool (3) with

lip (6) down.

d.

Using a 0.002 inch (0.051 mm) feeler gage,

check gap between seal (2) and plate (i)

No gap greater than 0.002 inch (0.051 mm)

is allowed.

VISUALLY INSPECT CARBON ELEMENTS

2.

(7) (OF SEAL (2) FOR CHIPS OR CRACKS. IF

DAMAGED, REPLACE SEAL (2).

Go on to Sheet 5

6-32.2 Change 4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |