|

|||

|

|

|||

|

Page Title:

APPLY SHORTENING COMPOUND TO PREFORMED PACKING |

|

||

| ||||||||||

|

|

TM 9-2835-255-34

NO. 2 AND 3 BEARING SEAL/PACKING RETAINER REPLACEMENT (INCLUDING INTERSHAFT SEAL)

(Sheet 48 of 49)

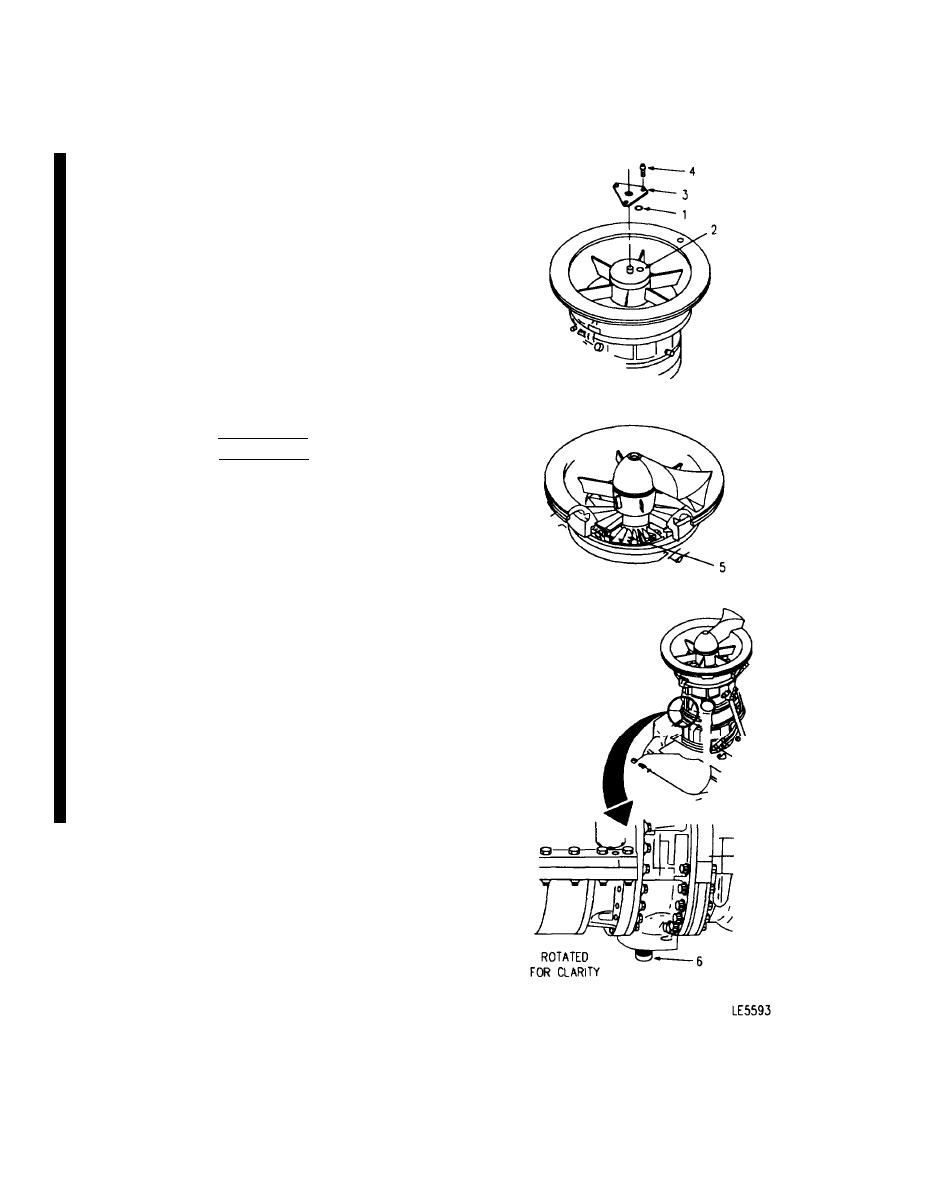

39. APPLY SHORTENING COMPOUND TO PRE-

FORMED PACKING (1) AND INSTALL INTO GROOVE

OF BEARING HOUSING LOW PRESSURE COM-

PRESSOR SPEED PICKUP HOLE (2).

40. INSTALL ACCESS COVER PLATE (3) AND SE-

CURE WITH THREE BOLTS (4) COATED WITH

ANTI-SEIZE COMPOUND. TIGHTEN BOLTS (4)

BETWEEN 40-45 LB-IN (4.52-5.08 N.M) TORQUE.

SAFETY WIRE BOLTS (4) USING SINGLE WIRE

METHOD. REMOVE RAGS FROM INLET

41. PERFORM A ROTATION CHECK OF LOW PRES-

SURE AND HIGH PRESSURE ASSEMBLIES TO

ENSURE PROPER INSTALLATION.

WARNING

Compressor blades are sharp and can cut

you. Be careful not to pinch fingers be-

tween blades and vanes when turning

compressor.

a.

Turn low pressure compressor blades (5) by

hand. Listen and feel for rubbing or binding.

b.

Turn high pressure compressor blades by

turning splined coupling (6) in both directions.

Listen and feel for rubbing or binding.

NOTE

If any of these conditions exist, repeat this

procedure as required to locate and cor-

rect problem.

42. INSTALL INLET AIR SPLITTER ASSEMBLY

(TM20-1).

Go on to Sheet 49

5-122

Change 6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |