|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2835-255-34

LOW PRESSURE ROTOR AND HOUSING ASSEMBLY (COMPRESSOR) AND HIGH PRESSURE

AXIAL COMPRESSOR AND ROTOR CLEANING (Sheet 18 of 21)

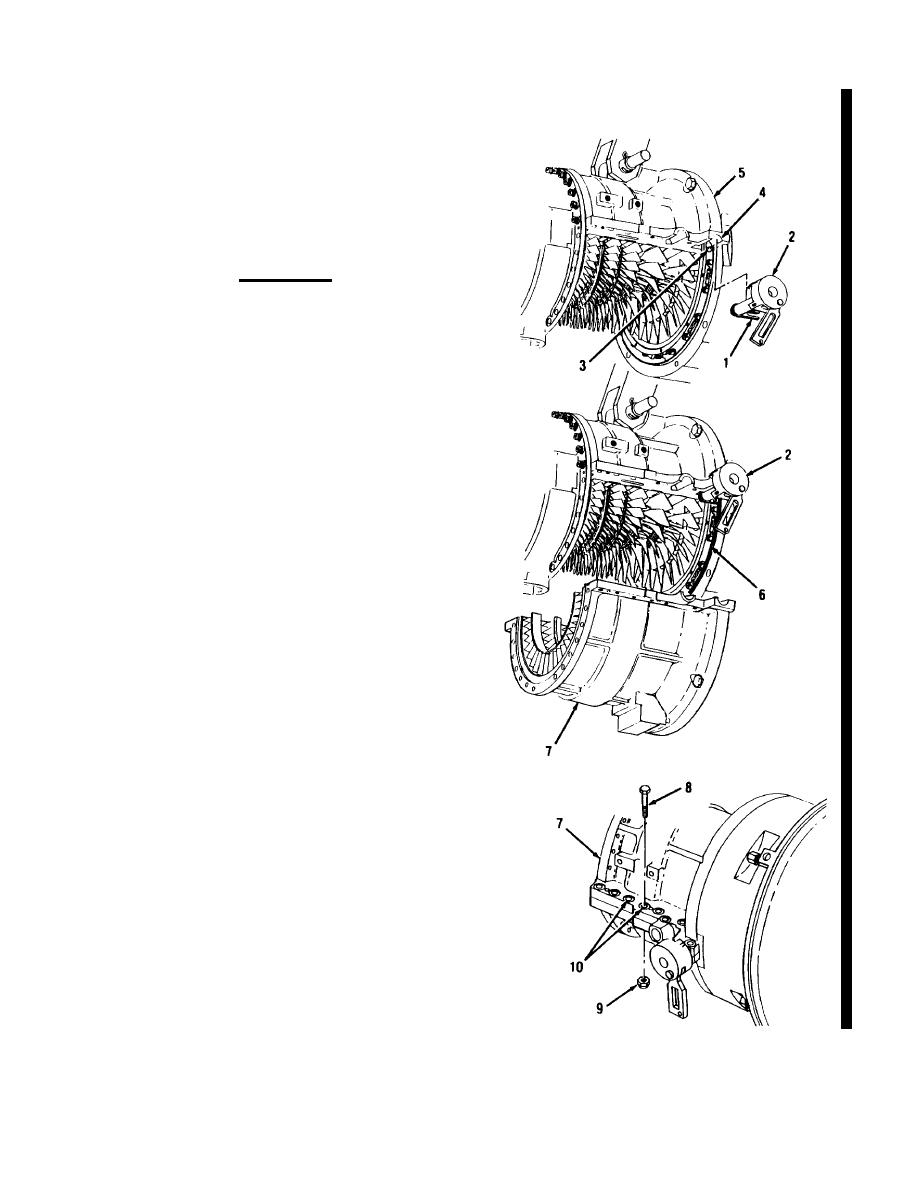

POSITION FORK END (1) OF BELLCRANK

35.

AND SHAFT (2) AROUUND BALL JOINT

(3), AND HOLD BELLCRANK AND SHAFT

(2) IN CUTOUT (4) OF LOW PRESSURE

CASE (TOP HALF) (5).

CAUTION

Packing (6) could get moved and pinched. Use care

when installing case and stator (bottom half (7) not

to move or pinch packing (6).

NOTE

Do not move bellcrank and shaft (2) when housing

(7) is installed. Fork end (1) will disconnect from

balljoint (3).

36. TURN BELLCRANK AND SHAFT (2) ALL

THE WAY TO THE RIGHT, AND INSTALL

LOW PRESSURE VANE AND STATOR

ASSEMBLY (BOTTOM HALF) (7). IN-

STALL NINE BOLTS (8) AND NINE NEW

NUTS (9).

a. Turn bellcrank and shaft (2) all the way to

the right.

b. Position vane and stator assembly (bottom

half) (7) on engine. Do not damage or

move packing (6).

NOTE

Only 9 of the 12 bolts (8) required are to be installed

at this time. Install bolts in two holes (10) only on

right side of case and stator assembly (7),

c. Apply antiseize compound to nine bolts

(8). Install nine bolts (8) and new nuts (9).

37. TORQ UE BOLTS (8) AND NUTS (9) BE-

TWEEN 100-110 LB-IN (11-12 N-m).

Go on to Sheet 19

Change 4 5-51

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |