|

|||

|

|

|||

|

Page Title:

SCREEN ASSEMBLY REPAIR (Sheet 1 of 1) |

|

||

| ||||||||||

|

|

TM 9-2835-255-34

FORWARD ENGINE MODULE (GEARBOX MODULE ATTACHED) REMOVAL

AND INSTALLATION (Sheet 7 of 7)

22. INSTALL POWER TURBINE STATOR FEEDBACK CONTROL ASSEMBLY (TM 20-1).

23. INSTALL POWER TURBINE STATOR CYLINDER ASSEMBLY (TM 20-1).

24. INSTALL THERMOCOUPLE BRANCHED WIRING HARNESS 3W106 (TM 20-1).

25. INSTALL LUBRICATING OIL TANK ASSEMBLY (TM 20-1).

26. FILL OIL TANK AND GEARBOX MODULE (LO -12)

End of Task

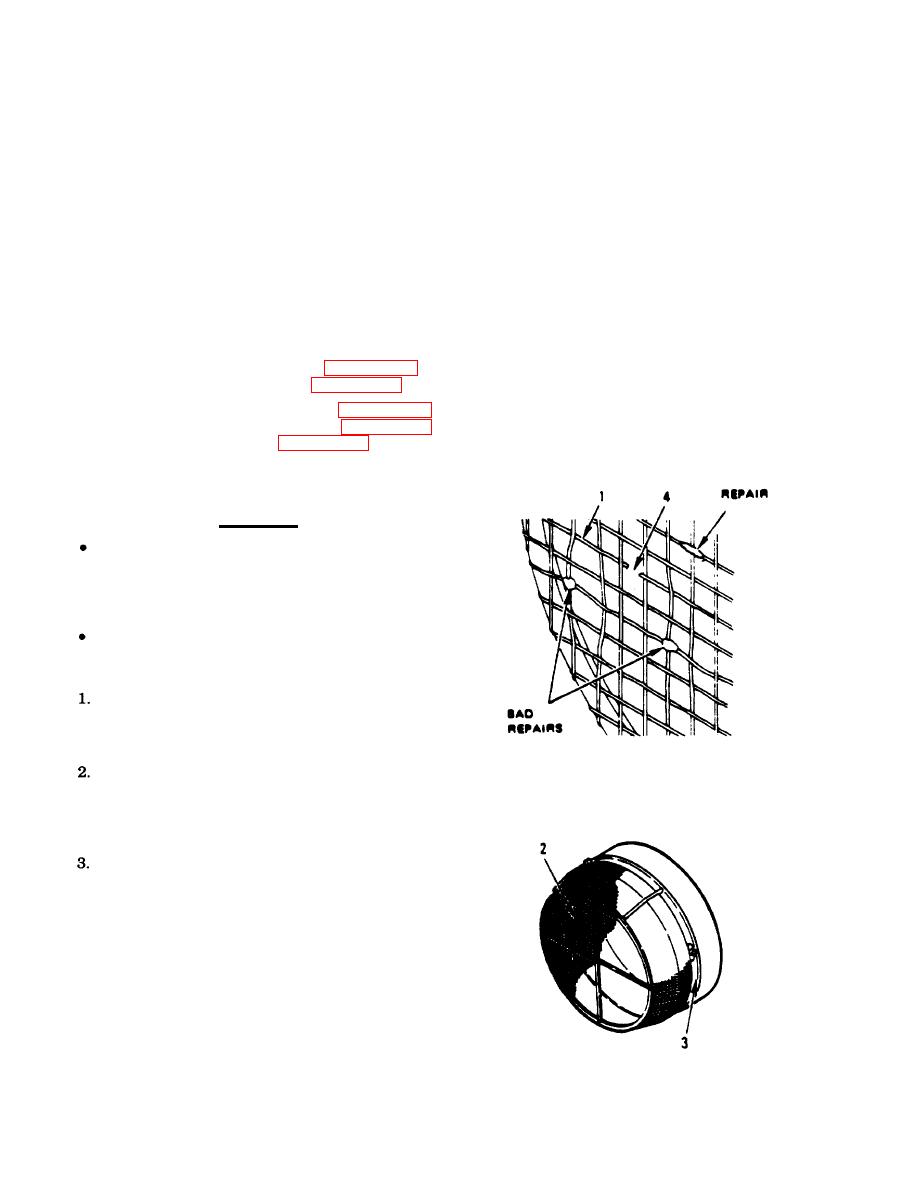

SCREEN ASSEMBLY REPAIR (Sheet 1 of 1)

TOOLS: Rubber mallet (Item 26, Appendix D)

Torch outfit (Item 25, Appendix D)

SUPPLIES: Brazing alloy (Item 4, Appendix B)

Brazing alloy (Item 5, Appendix B)

Flux (Item 8, Appendix B)

GOOD

REPAIR:

CAUTION

Do not bend wire (1) more than 90 when making

repairs. Sharp bending of wire (1) may cause it to

become weak or crack, If wire (1) is sucked into

engine, it will cause compressor damage.

Do not allow large amounts of filler metal to

form. They could break off and be sucked into

engine, causing compressor damage.

REPAIR DEFORMED SCREEN (2) BY

PLACING IT AGAINST SOMETHING

HARD. GENTLY TAP UNTIL SHAPE IS

RESTORED.

TORCH SILVER BRAZE BROKEN OR

SEPARATED WIRES (1) AT THE

Attachment BAND (3). USE BRAZING

ALLOY (ITEM 5, APPENDIX B) AND

FLUX.

LOOK AT ALL OTHER WIRES (1) FOR

BREAKS. IF GAP (4) IS GREATER THAN

0.030-INCH (0.762 MM), REPLACE SCREEN

(2). OTHERWISE TORCH SILVER BRAZE

BROKEN WIRE (l). USE BRAZING ALLOY

(ITEM 4 OR 5 APPENDIX B) AND FLUX.

End of Task

5-31

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |