|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Engine Tune-Up instructions (Cont)

19-11. ENGINE COMPRESSION CHECK (Cont).

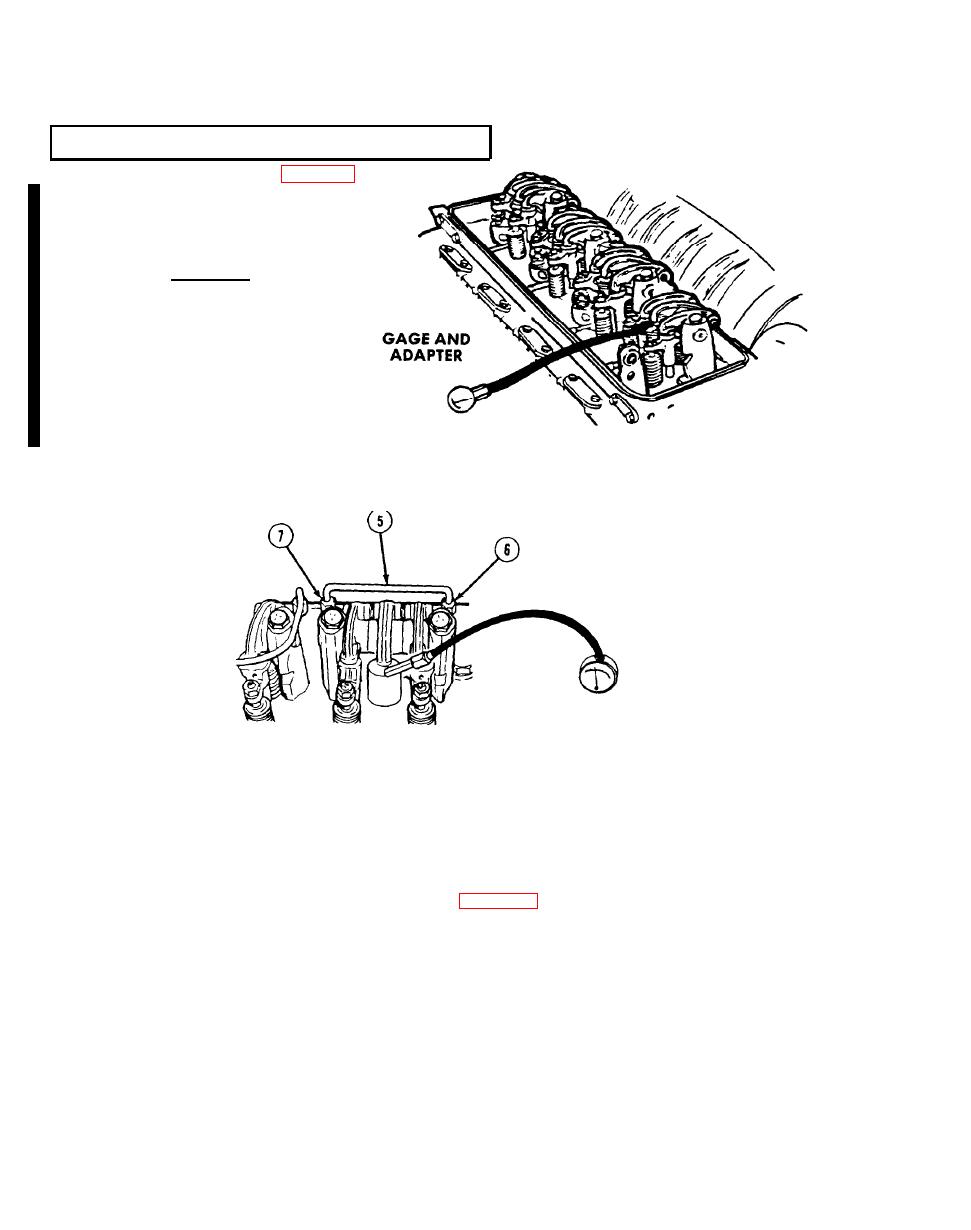

Remove fuel injector (para 12-2).

(3)

Install adapter and gage.

(4)

Install bolt, clamp, and convex

(5)

washer, tighten to 20-25 ft-lb

(27-34 Nm).

CAUTION

Shorter screws must be used with retarders

off. Check shorter screws for oil passage

hole. If shorter screws are not used,

equipment damage could occur,

Secure rocker arm pin and supports

(6)

using shorter screws. Tighten

to 45 (61) then 88-92 ft-lb

(119-125 Nm).

Install adapter and gage.

(7)

Install jumper connection (5) between fuel inlet (6) and return manifold connector (7).

(8)

NOTE

Engine must be running to obtain compression.

Start engine and run at 600 to 670 rpm. Record compression pressure shown on gage.

(9)

NOTE

The compression pressure in any one cylinder at a given altitude above sea level

must not be less than the minimum shown in Table 19-1. The variation in

compression pressures between cylinders must not exceed 25 psi (172 kPa) at 635

rpm.

Repeat steps 3 through 9 on each cylinder.

(10)

19-32 Change 2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |