|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Fuel Injector Maintenance Instructions (Cont)

12-3. FUEL INJECTOR REPAIR (CONT).

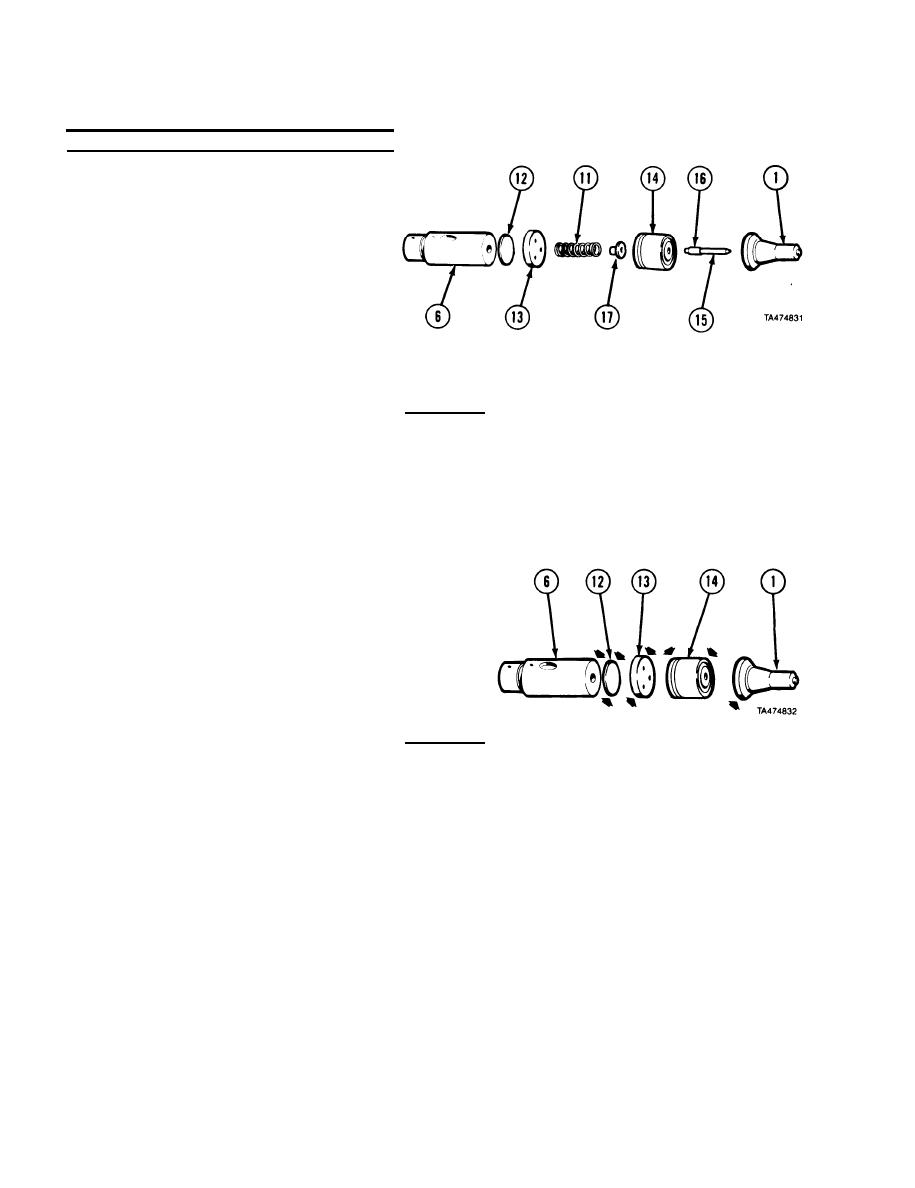

(25) Inspect valve spring (11 ) for

wear or damage. Replace if worn

or damaged.

(26) Inspect sealing surfaces of

injector valve parts. Use

magnifying glass and inspect

bushing (6), check valve (12),

check valve cage (13), and spring

cage (14) for burrs, nicks,

erosion, and scratches. Replace

damaged parts.

(27) Inspect seating area of needle valve (15) for wear or damage. Inspect needle quill (16) and

contact point with spring seat (17).

CAUTION

Make sure no polishing compound gets on lapped surfaces located higher than

end of spray tip. Any lapping on these surfaces can alter near-perfect fit between

needle valve and tip.

(28) Inspect needle valve seat in spray tip (l). Polish seat area with polishing stick from injector

service kit coated with polishing compound.

(29) Insert polished tapered end of polishing stick directly into center of spray tip (1) until it bottoms.

Rotate polishing stick 6 to 12 times with light pressure.

(30) Lap sealing surfaces (see arrows) of injector

valve parts. Follow given lapping procedures for

bushing (6), check valve (12), check valve

cage (13), spring cage (14), and spray tip (1).

(31) Clean lapping blocks with compressed air only.

(32) Spread lapping and grinding compound on first

lapping block.

CAUTION

Do not press on parts when lapping, but use enough pressure to keep part flat

q

on lapping block or injector malfunction will result.

Do not lap parts excessively. Inspect injector parts for minimum thickness.

q

Excessive lapping can result in improper seating surfaces and injector

malfunction.

NOTE

Minimum thicknesses of used injector parts are:

Spray tip (shoulder) O. 199-in. (5.05 mm)

Check valve cage 0.165 to 0.163-in. (4.19 to 4.14 mm)

Check valve 0.022-in. (0.55 mm)

Valve spring cage 0.602-in. (15.29 mm)

(33) Place injector part flat on lapping block and using a figure-eight motion, move part back and

forth.

(34) Wash injector parts in dry cleaning solvent after lapping.

12-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |