|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Fuel Injector Maintenance Instructions (Cont)

12-3. FUEL INJECTOR REPAIR (CONT).

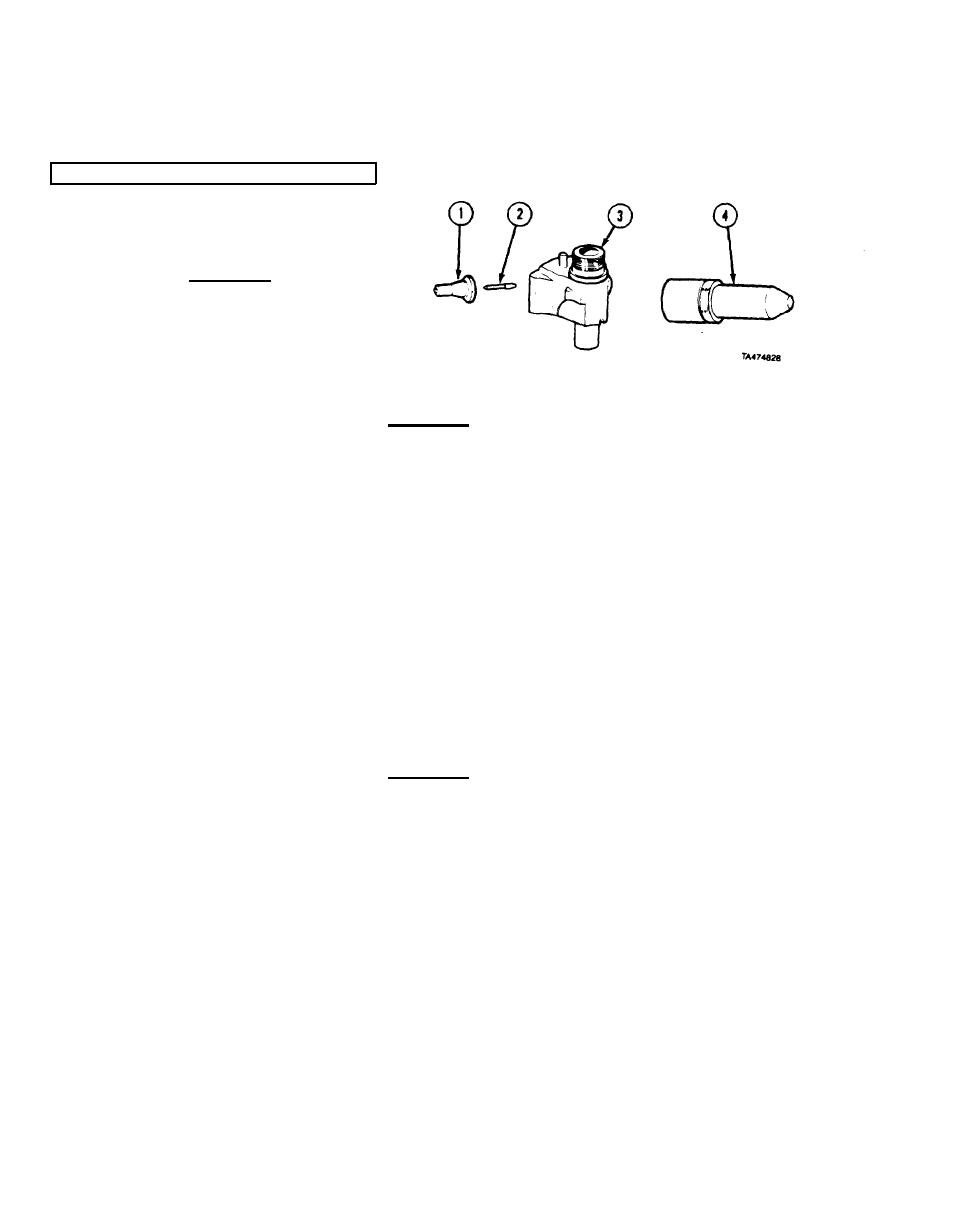

(3) Clean carbon from inside spray tip (1) by

soaking in methyl ethyl ketone for 15

minutes.

CAUTION

Use care when inserting carbon remover in

spray tip. Contact with valve seat can

damage valve.

(4) Clean spray tip (1) using carbon remover

from injector service kit.

(5) Clean spray tip (1) in diesel fuel oil, and dry with compressed air.

CAUTION

Do not buff excessively. Do not use steel wire buffing wheel or damage to spray

tip holes can result.

(6) Clean needle valve (2) and outside surface of injector body (3), injector valve nut (4), and spray

tip (1) with brass wire brush. Use spray tip carbon remover to hold spray tip against brass wire

brush.

(7) Hone a 0.006 in. (0.152 mm) spray hole wire from injector service kit until free of burrs. Taper

one end of-spray hole wire on wire sharpening stone from injector service kit.

(8) Clean orifices in spray tip (1) using pin vise and spray hole wire from injector service kit.

(9) Clean and brush passages in injector body (3), using fuel hole cleaning brush and rack hole

cleaning brush from injector service kit.

(10) Dry and blow out passages with compressed air.

(11) Insert injector body reamer in injector body (3) turning clockwise until bore face is reamed.

NOTE

Use straight fluted reamer with 0.375-in. diameter.

(12) Insert reamer into ring bore inside injector body (3) and turn clockwise to remove bum.

(13) Wash injector body (3) in container of diesel fuel oil.

(14) Dry injector body (3) with compressed air.

CAUTION

When removing carbon deposits, use care not to remove excess metal or cause

burrs on spray tip seat. Remove only enough metal to make a clean uniform seat

to prevent leakage between seat and nut. Excessive reaming can damage injector

parts.

(15) Remove carbon deposits from lower inside diameter of injector valve nut (4) using taper reamer

from injector service kit.

(16) Inspect seating surface of injector valve nut (4) for nicks, burrs, erosion, or scratches.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |