|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Blower and Water Pump Drives Maintenance Instructions (Cont)

10-2. BLOWER DRIVE SUPPORT REMOVAL/REPAIR/INSTALLATION (CONT).

c.

Cleaning/lnspection.

WARNING

. Adhesives, solvents, and sealing compounds can burn easily, can give off

harmful vapors, and are harmful to skin and clothing. To avoid injury or death,

keep away from open fire and use in well-ventilated area. If adhesive, solvent,

or sealing compound gets on skin or clothing, wash immediately with soap and

water.

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa).

Use only with effective chip guarding and personal protective equipment

(goggles/shield, gloves, etc.).

(1)

Clean all metal parts with dry cleaning solvent.

Dry parts, except bearings, with compressed air. Let bearings air dry.

(2)

(3)

Make sure oil passages are clear.

(4)

Inspect threads for damage. Replace parts if damaged.

Check that thrust washer thickness is between 0.2350 and 0.2450-in. (5.969 and 6.223 mm).

(5)

Inspect thrust washer for scoring.

Check that two thrust bearings thickness is between 0.0590 and 0.0610-in. (1.498 and

(6)

1.549 mm). Inspect thrust bearings for scoring.

(7)

Check that inside diameter of support bushing is between 1.6260 and 1.6265-in. (41.300 and

41.313 mm). Record diameter.

(8)

Check diameter of drive hub at base. It must be between 1.6240 and 1.6250-in. (41.249 and

41.275 mm). Record diameter.

Subtract diameter recorded in step (7) from diameter recorded in step (8). Make sure that

(9)

clearance between drive hub and support bushing is between 0.0010 and 0.0025-in. (0.025 and

0.063 mm) when parts are new. Limit is 0.0050-in. (0. 127 mm) for used parts.

(10)

If support bushing is worn beyond limits in step (7), replace bushings.

(11)

Inspect drive gear teeth for scoring, pitting, and burning (blue or dark spots). Replace if teeth are

defective.

Inspect auxiliary drive hub for cracks, breaks, stripped threads or worn-out splines in bore.

(12)

Replace if damaged.

(13)

Inspect both flex spring plates for cracks, distortion, or other damage. Replace if defective.

d. Assembly.

NOTE

If bushing were removed, do step (1). If not, go to step (2).

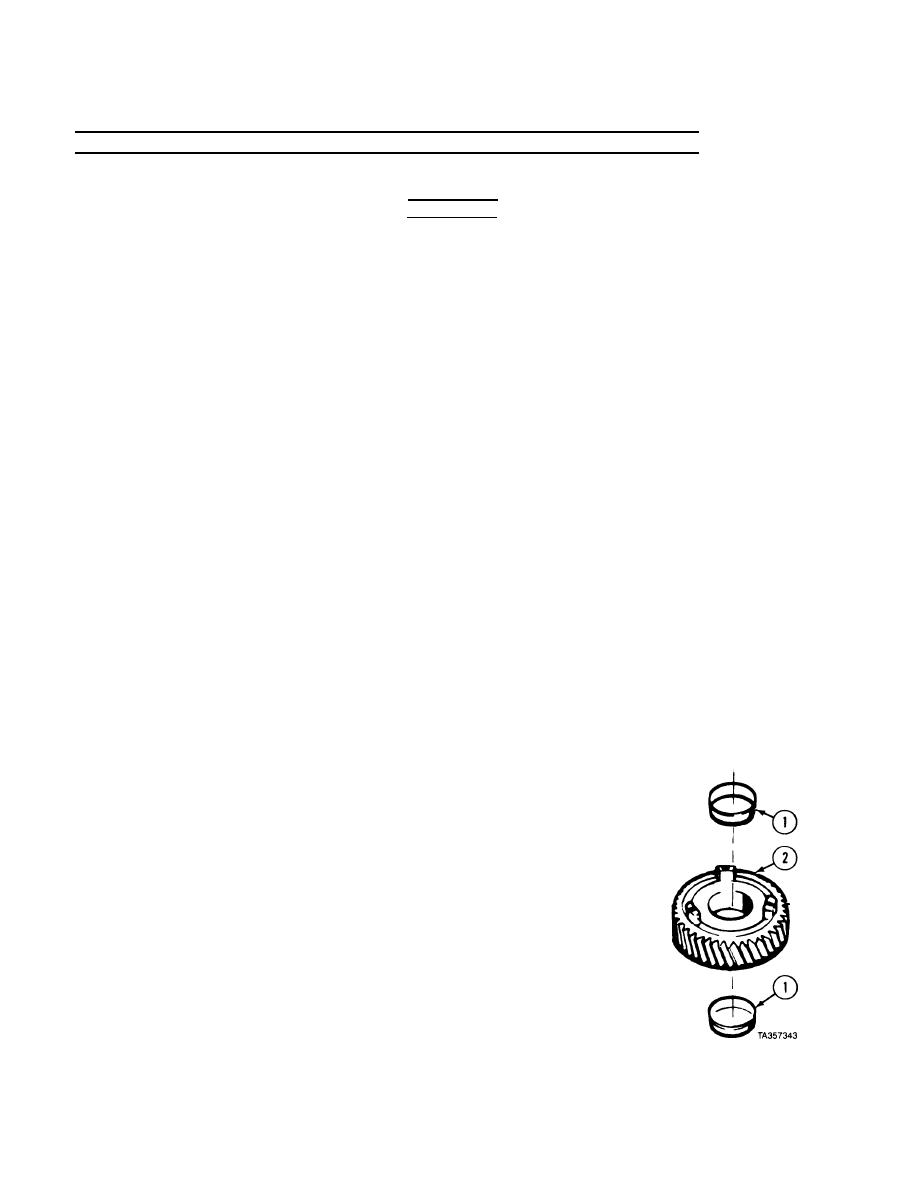

(1) Press two bushings (1) into drive gear (2) flush with drive gear.

10-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |