|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Oil System Maintenance Instructions (Cont)

c. C l e a n i n g / l n s p e c t i o n .

WARNING

Adhesives, solvents, and sealing compounds can burn easily, can give off harmful

vapors, and are harmful to skin and clothing. To avoid injury or death, keep away

from open fire and use in well-ventilated area, If adhesive, solvent, or sealing

compound gets on skin or clothing, wash immediately with soap and water.

(1) Clean regulator with dry cleaning solvent.

WARNING

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use

only with effective chip guarding and personal protective equipment

(goggles/shield, gloves, etc.).

(2) Dry regulator with compressed air.

(3) Inspect all parts for damage. Replace damaged parts.

(4) Make sure regulator valve moves freely in valve body.

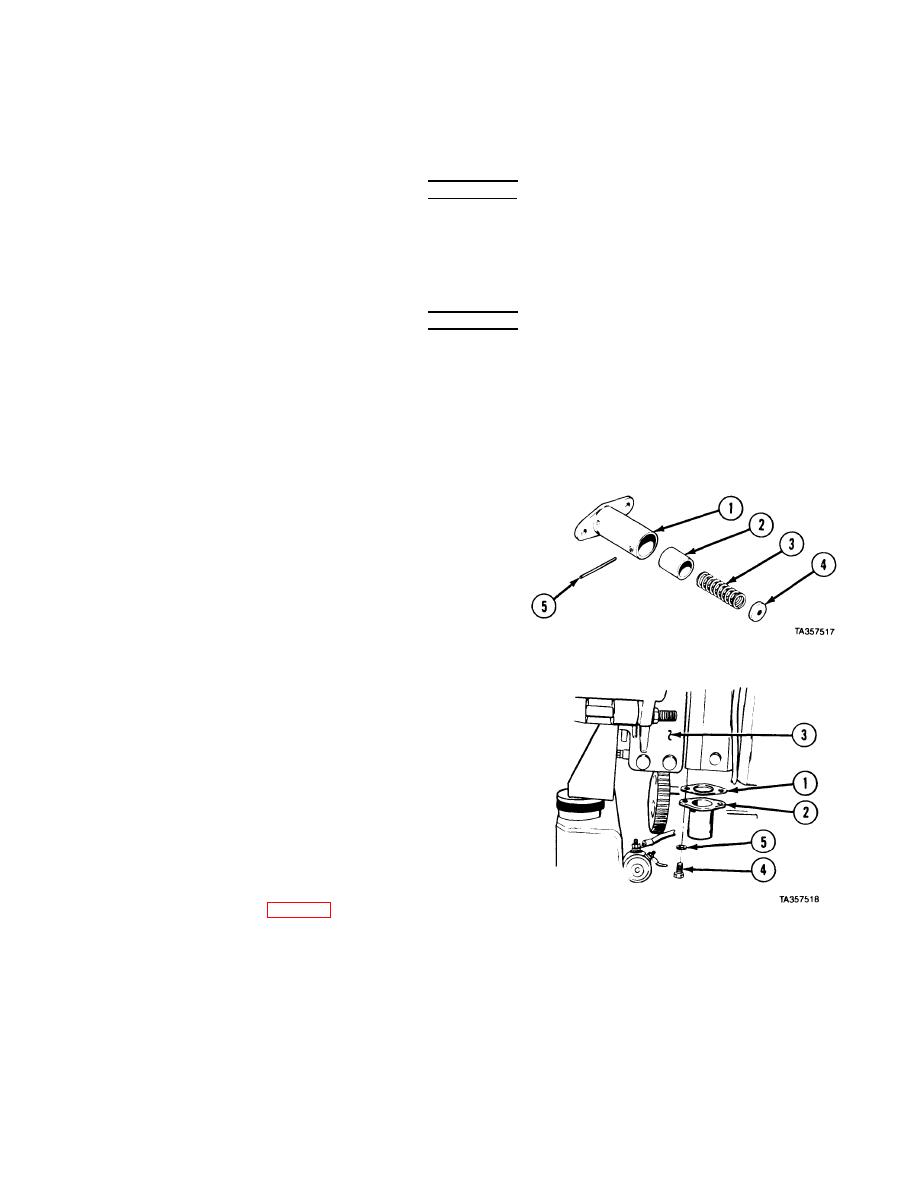

d . Assembly.

(1) Install regulator body (1) in vise with soft jaws.

(2) Apply lubricating oil to valve (2) and insert into

regulator body (1), closed end first.

(3) Insert spring (3) into regulator body (1).

(4) Install spring seat (4), open end first, and

compress spring (3).

(5) Install pin (5).

e. Installation.

(1) Install gasket (1) and oil pressure regulator (2) on

engine (3).

(2) Install two screws (4) and washers (5).

(3) Tighten screws (4) to 30 to 35 lb-ft (41 to 47 Nm).

f. Follow-on Maintenance.

(1) Install oil pan (para 8-3).

(2) Start engine (TM 9-2320-279- 10).

(3) Check oil pressure (TM 9-2320-279-10).

END OF TASK

8-21/(8-22 blank)

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |