|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

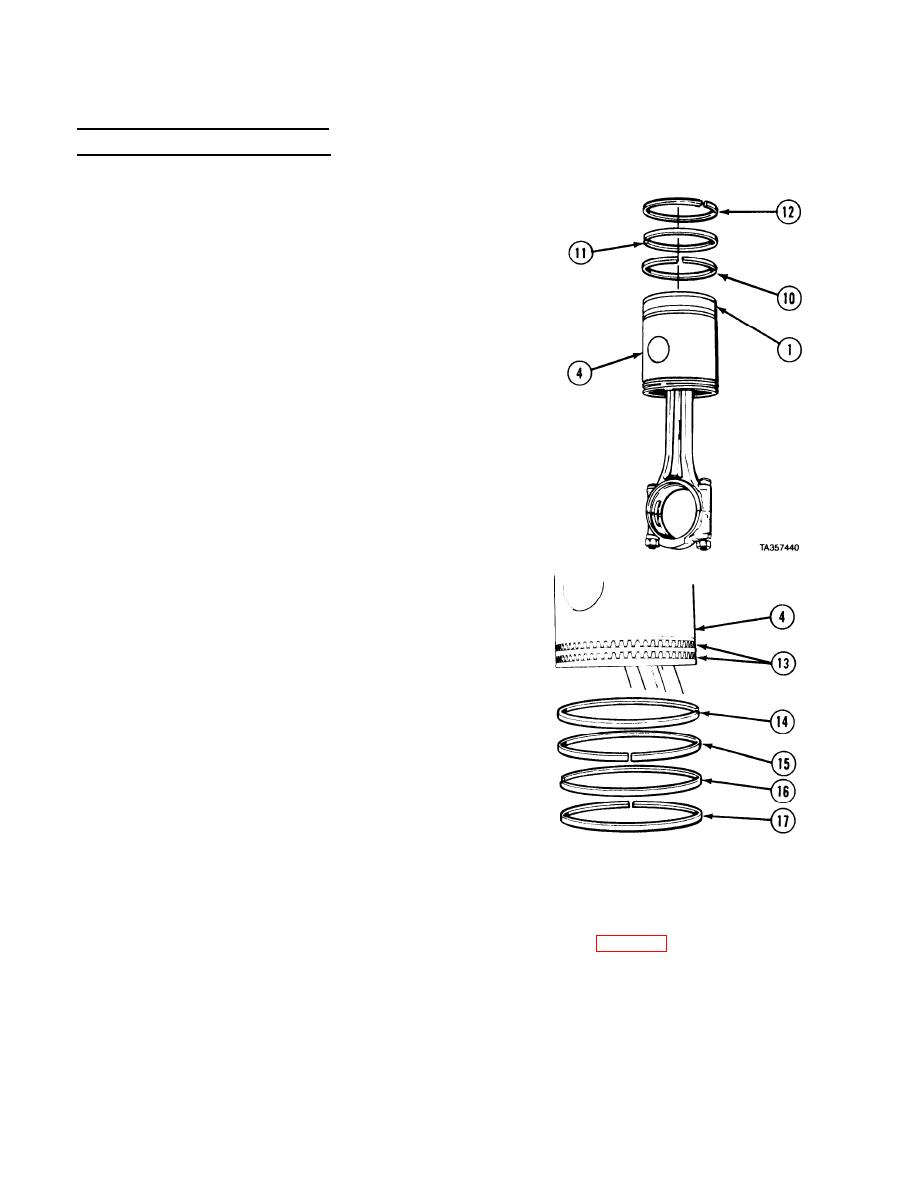

Piston and Connecting Rod Maintenance Instructions (Cont)

6-3. PISTON REPAIR (CONT).

NOTE

Replace piston rings in sets only.

(19) Coat piston crown (1) and skirt (4) with lubricating oil.

NOTE

Position ring gaps 1200 apart, around piston crown.

(20) Install lower piston ring (10) (ring without marks).

(21) Install middle piston ring (11) (ring with one punch mark)

toward top of piston crown (1).

(22) Install top piston ring (12) (ring with two punch marks)

toward top of piston crown (1).

CAUTION

To prevent damage to oil rings when piston is

installed in ring compressor, make sure ends of

expander rings do not overlap.

(23) Install two oil ring expanders (13) on piston

skirt (4) with ends pointing upward.

NOTE

Install oil rings wit h beveled edge facing

upward.

(24) Install chrome nonsloted, oil ring (14) with

gap posit ion 180 degrees from gap in

expander ring (1 3).

(25) Install nonslot ted oil ring (15) with gap

positioned 90 degrees from gap in oil

TA357441

ring (14).

(26) Install oil ring (16) wit h black, slotted bottom down and gap positioned 180 degrees from gap in

expander ring ( 13).

(27) Install oil ring ( 17) with black slotted bot tom down and gap positioned 90 degrees from gap in oil

ring (16).

END OF TASK

6-12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |