|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

Piston and Connecting Rod Maintenance Instructions (Cont)

6-3. PISTON REPAIR (CONT).

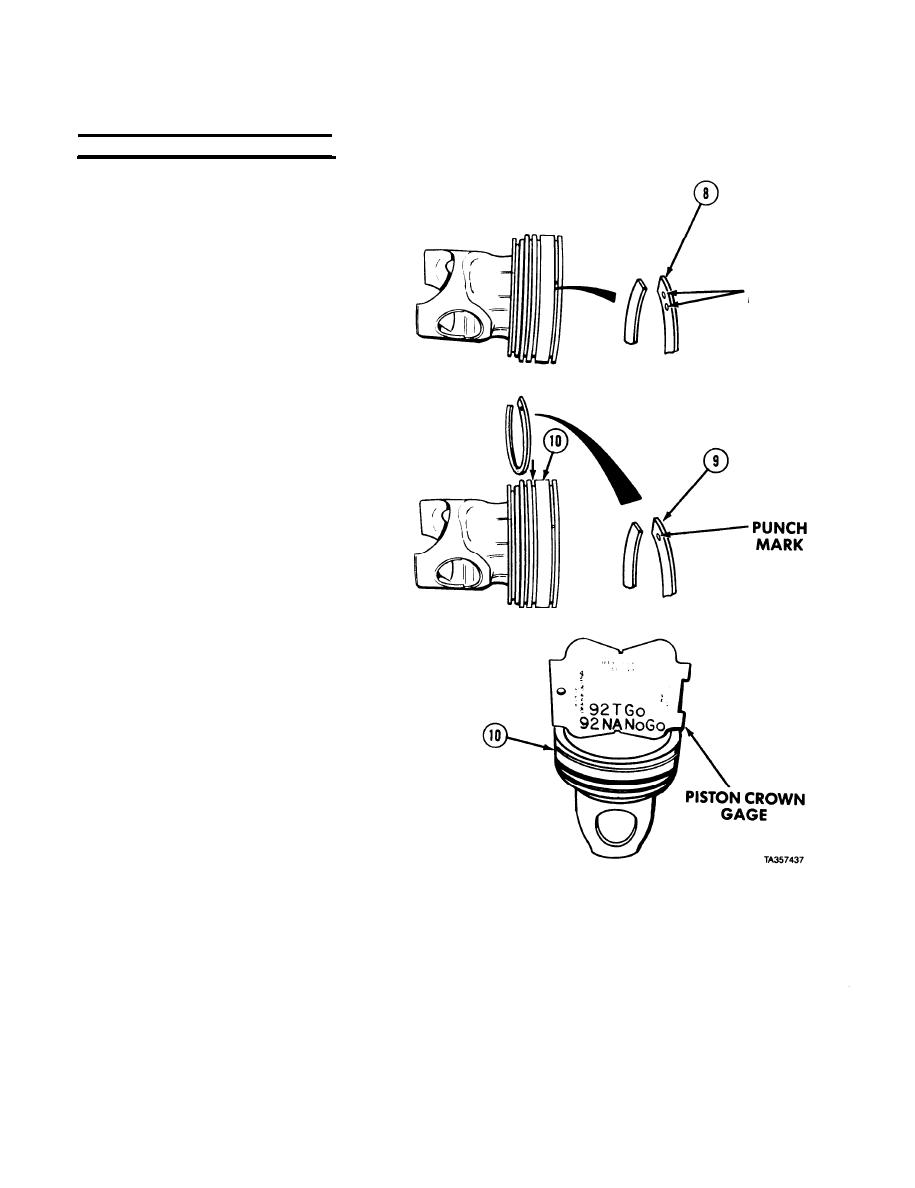

(12) Install top compression ring (8)

with two punch marks up.

(13) Measure clearance between ring (8)

and groove; clearance should be

0.001 to 0.005 in. (0.025 to

0.13 mm).

PUNCH

MARKS

TA357435

(14) Put middle compression ring (9)

with one punch mark in groove on

piston dome (10); clearance should

be 0.010 to 0.013 in. (0.25 to

0.33 mm).

(15) Put lower compression ring in

groove on side of piston dome (10);

clearance should be 0.004 to

0.007 in. (0.10 to 0.18 mm).

(16) Put seal ring in groove on side of

piston dome (10); clearance should

be 0.0010 to 0.003 in. (0.025 to

0.08 mm).

TA357436

(17) Using edge of piston crown gage marked "92T

Go, 92 NA No Go", check piston dome (10) by

setting piston crown gage into bowl of piston

crown. Gage must rest fully down on rim of

piston crown.

6-10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |