|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

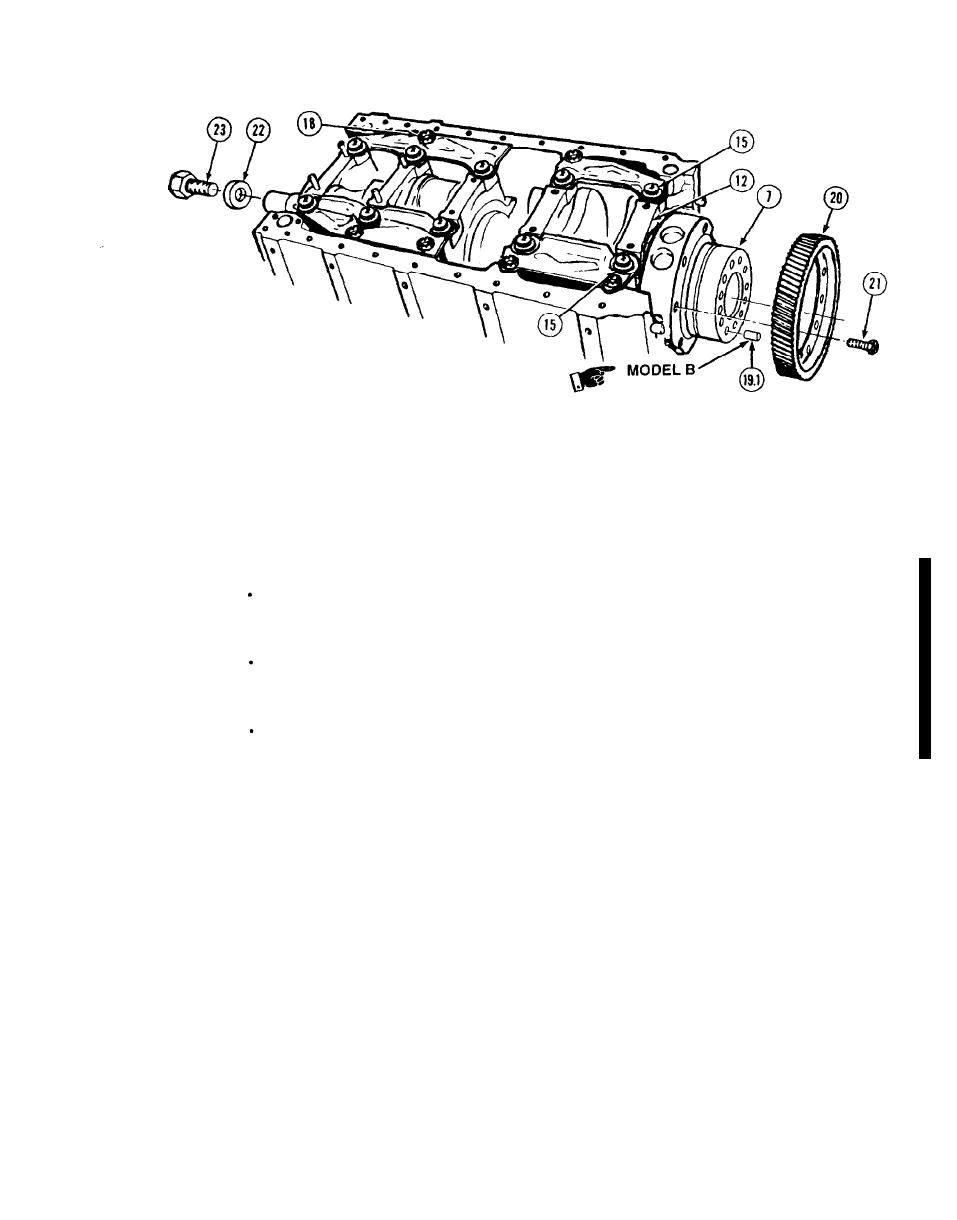

TM 9-2815-224-34&P

Crankshaft Maintenance Instructions (Cont)

Tighten two screws (15) on rear bearing cap (12) to 50 lb-ft (68 Nm).

(33)

Strike both ends of crankshaft (7) two or three blows with soft-face hammer.

(34)

Strike rear bearing cap (12) with soft-face hammer.

(35)

Tighten two screws (15) on rear bearing cap (12) to 110 lb-ft (149 Nm).

(36)

Strike rear bearing cap (12) with soft hammer.

(37)

Tighten two screws (15) on rear bearing cap (12) 230 to 240 lb-ft (312 to 325 Nm).

(38)

Tighten seven screws (18) to 75 lb-ft (102 Nm).

(39)

NOTE

There are two models of crankshafts and timing gears. Model B crankshaft, used with

serial No. 8VF-098597 and later, has a roll pin to locate the timing gear. Model B

timing gear, used in the same engines,has a groove to accept the roll pin.

Mode1 A and B parts are interchangeable with the following exception: do not use roll

pin with Mode1 B timing gear and Model A crankshaft, or Mode1 A timing gear and

Mode1 B crankshaft.

Perform step (39.1) for Mode1 B crankshaft and timing gear only.

Install roll pin (19.1) in crankshaft (7).

(39.1)

Install timing gear (20) and six screws (21).

(40)

Install spacer (22) and screw (23) on end of crankshaft (7).

(41)

Soldier A holds front end of crankshaft (7) while Soldier B tightens six screws (21) to 40 lb-ft.

(42)

(54 Nom).

Remove screw (23) and spacer (22) from crankshaft (7).

(43)

4-26.1/(4-26.2 blank)

Change 2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |