|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2815-224-34&P

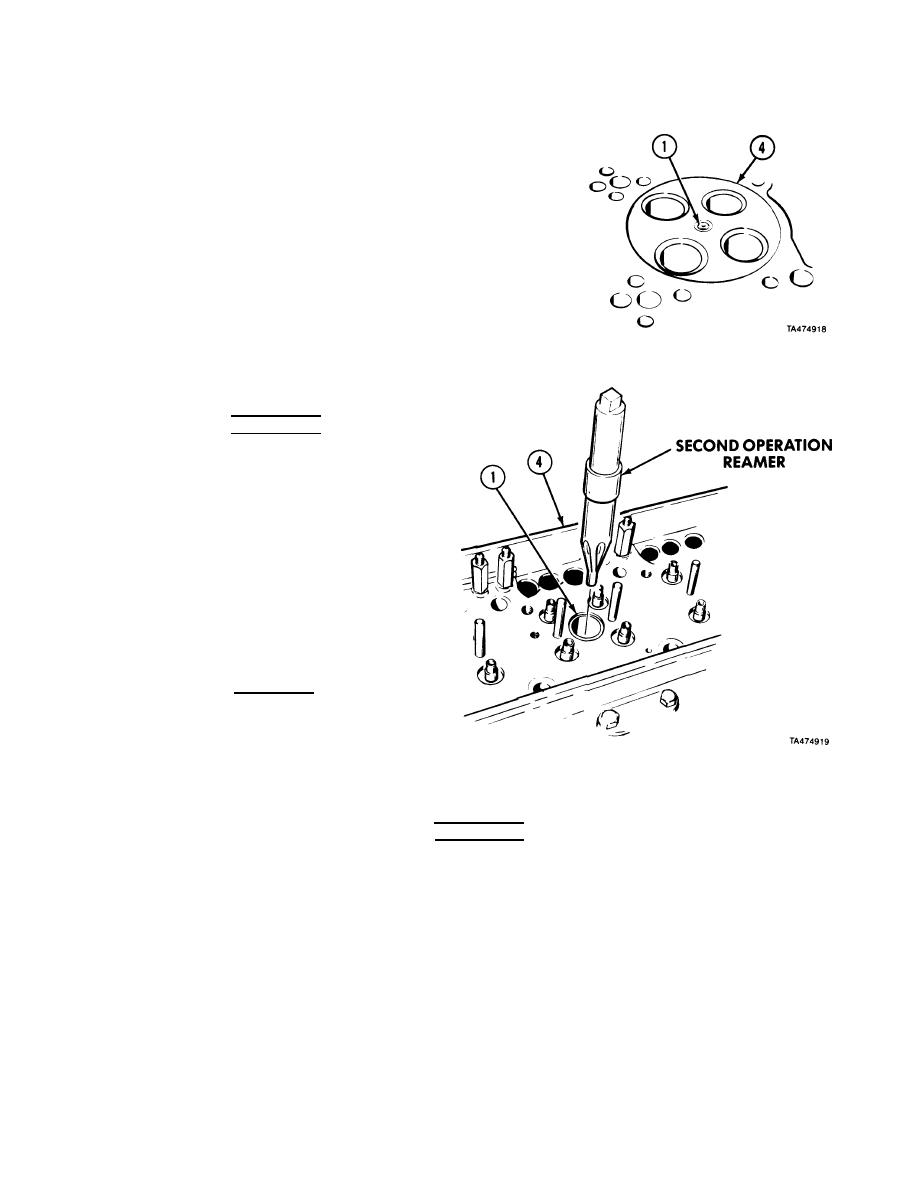

Cylinder Head Maintenance Instructions (Cont)

(14) Measure depth of gage in injector tube (1) beneath face

of cylinder head (4) using sled gage.

(15) Measurement must be 0 0.014 in, (0.36

mm). If

measurement is within tolerance, do steps

(22) and (23).

If measurement is more than 0.014 above

0 reading,

replace tube (1) and do steps (16) through

(21).

(16) Set cylinder head (4) right side up on

work surface.

WARNING

Adhesives, solvents, and sealing

compounds can burn easily, can give off

harmful vapors, and are harmful to skin

and clothing. To avoid injury or death,

keep away from open fire and use in

well-ventilated area. If adhesive,

solvent, or sealing compound gets on

skin or clothing, wash immediately with

soap and water.

(1 ?" Wash injector tube (1) with dry

cleaning solvent.

(18) Lubricate reamer blades while

reaming injector tubes.

CAUTION

Counterclockwise reaming will damage

reamer blades and injector tube.

(19)

Ream injector tube (1) clockwise.

(20)

Clean filings from injector tube (l).

(21)

Repeat steps (17) through (20) until protrusion gage is flush 0.014 in. (0.36 mm).

(22)

Clean injector tube (1) with dry cleaning solvent.

WARNING

Compressed air used for cleaning purposes will not exceed 30 psi (207 kPa). Use

only with effective chip guarding and personal protective equipment

(goggles/shield, gloves, etc.).

(23) Dry with compressed air.

3-57

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |