|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM9-2815-224-34&P

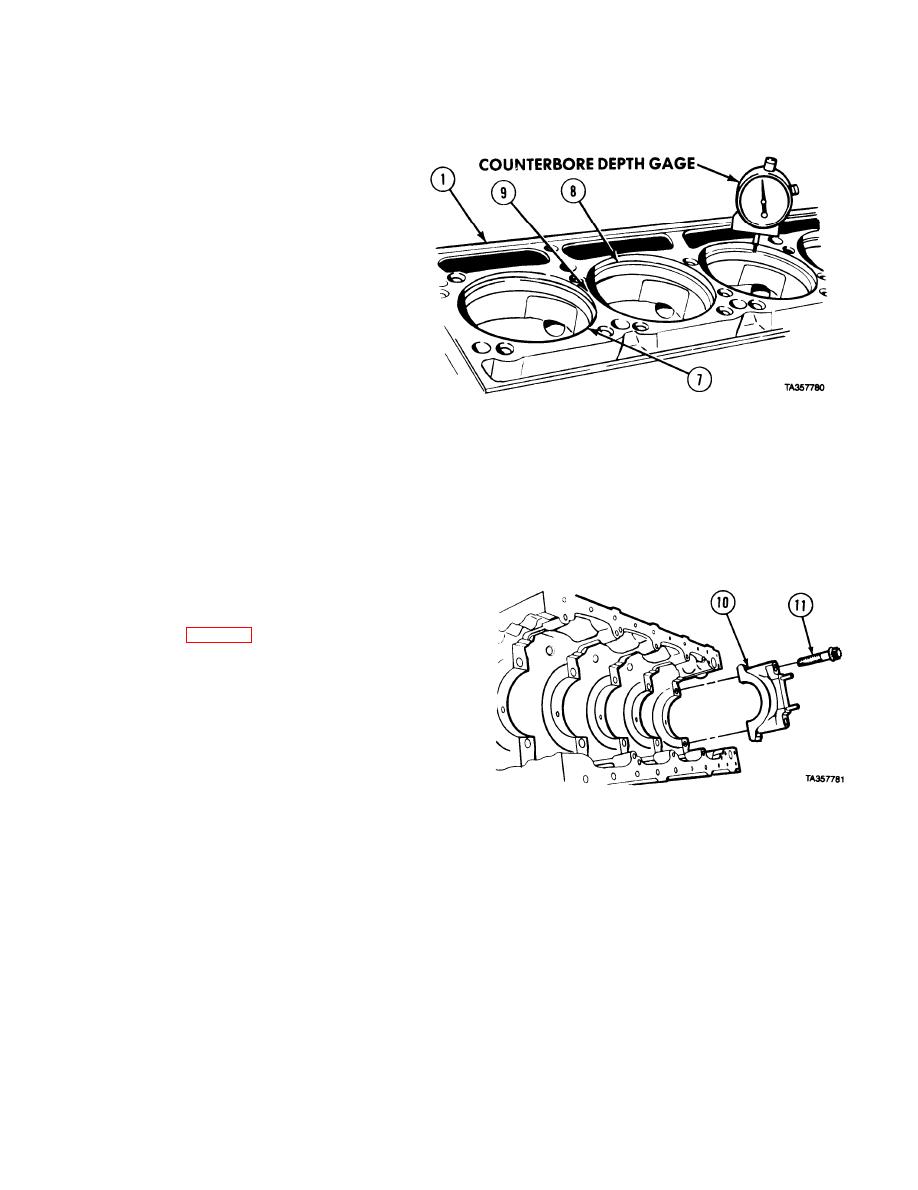

Engine Block Maintenance Instructions (Cont)

NOTE

Cylinders may be counterbored

to either of two depths.

(14) Using counterbore depth gage,

measure depth of counterbore (8).

If depth is not between ` `

0.4755-in. (12. 13 mm) and

0.477-in. (12.12 mm) or

between 0.4905-in.

(12.46 mm) and 0.4920-in.

(12.50 mm) and cannot be

brought into limits by

installing cylinder liner insert,

replace engine block (1).

(15) If counterbore (8) varies more than 0.0015-in. (0.04 mm) around edge of cylinder, replace engine

block (l).

NOTE

If two adjacent cylinders are in different counterbore depth ranges measured in

step (14) above, step (16) does not apply.

(16) If difference between any one adjacent cylinder counterbores (8) measured at their closest

point (9) is more than 0.0015-in. (0.04 mm), replace engine block (l).

NOTE

Main bearing caps must be installed in proper

positions in engine block, as marked during

removal (para 4-5). Make sure caps are firmly

seated in engine block and main bearing shells

are removed.

(17) Install five main bearing caps (10) and ten

screws (11 ).

(18) Tighten screws (11) up snug.

(19) Strike caps (10) with soft-face hammer to seat

them.

(20) Tighten screws (11) to 50 lb-ft (68 NZm).

(21) Tighten screws (11) to 110 Ib-ft (149 Nm).

(22) Tighten screws (11) to 250 to 260 lb-ft (339 to

352 Nm).

3-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |