|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

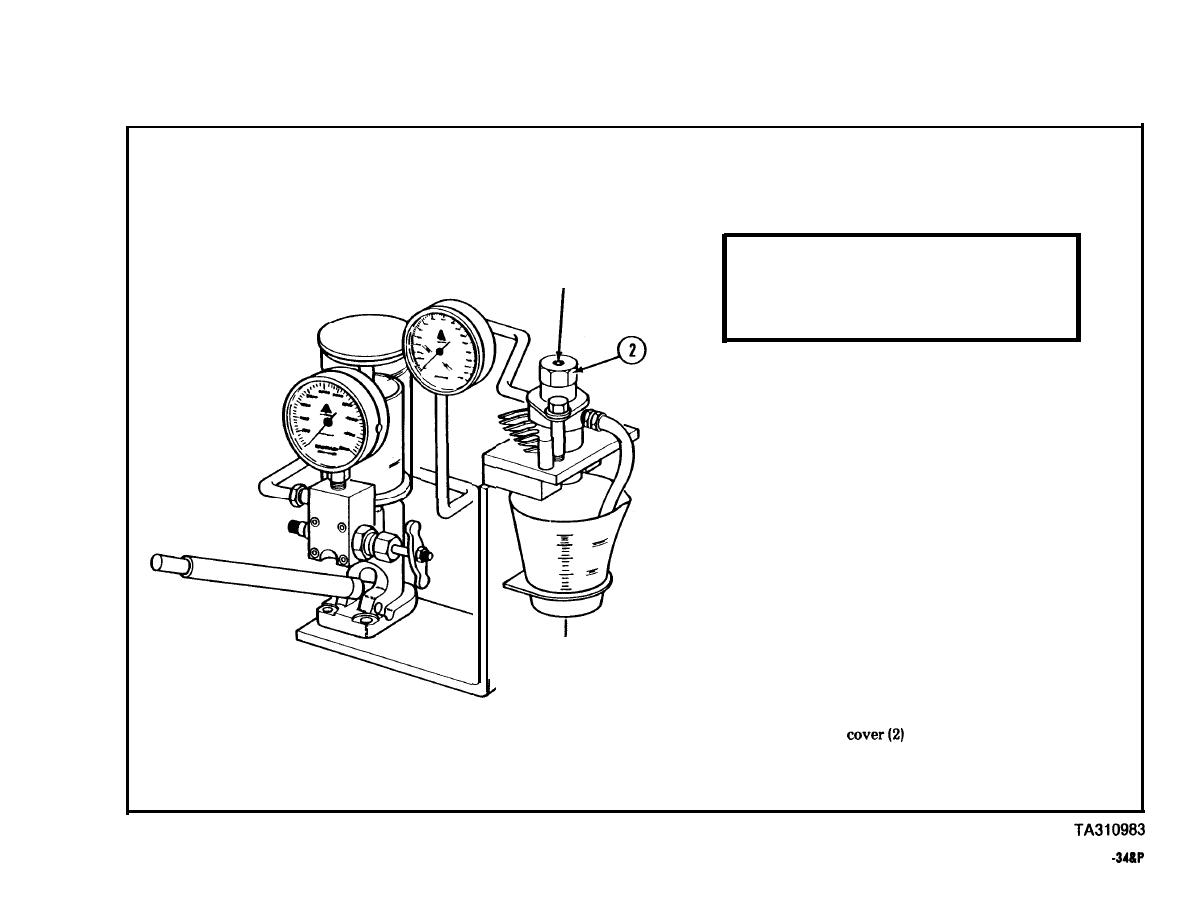

TESTS AND ADJUSTMENTS (CONTINUED)

NOZZLE ASSEMBLY

WARNING

Q

1

Do not allow nozzle spray to contact skin. Diesel

fuel under pressure can penetrate flesh and cause

serious injury and infection.

NOTES

Nozzle and holder assemblies are designed to

open at 1900-1950 psi. After several hundred

hours of operation, nozzle pressure will decrease

to an acceptable 1750 psi. Use nozzle pressure

tester to test and adjust nozzle assemblies.

If streamers of fuel are visible or nozzle drips

before reaching 1750 psi minimum opening

pressure, nozzle is dirty or defective. If dirty,

clean nozzle and valve (p 3-24).

If defective, replace nozzle and valve together.

Some chattering of nozzle is normal during

pressure tests.

/

A Remove setscrew (l).

B Back off adjusting nut

several turns.

TM 9-2815-221

4-13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |