|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

3-82

TM

INJECTION PUMP

REPAIR .[CONTINUED)

.

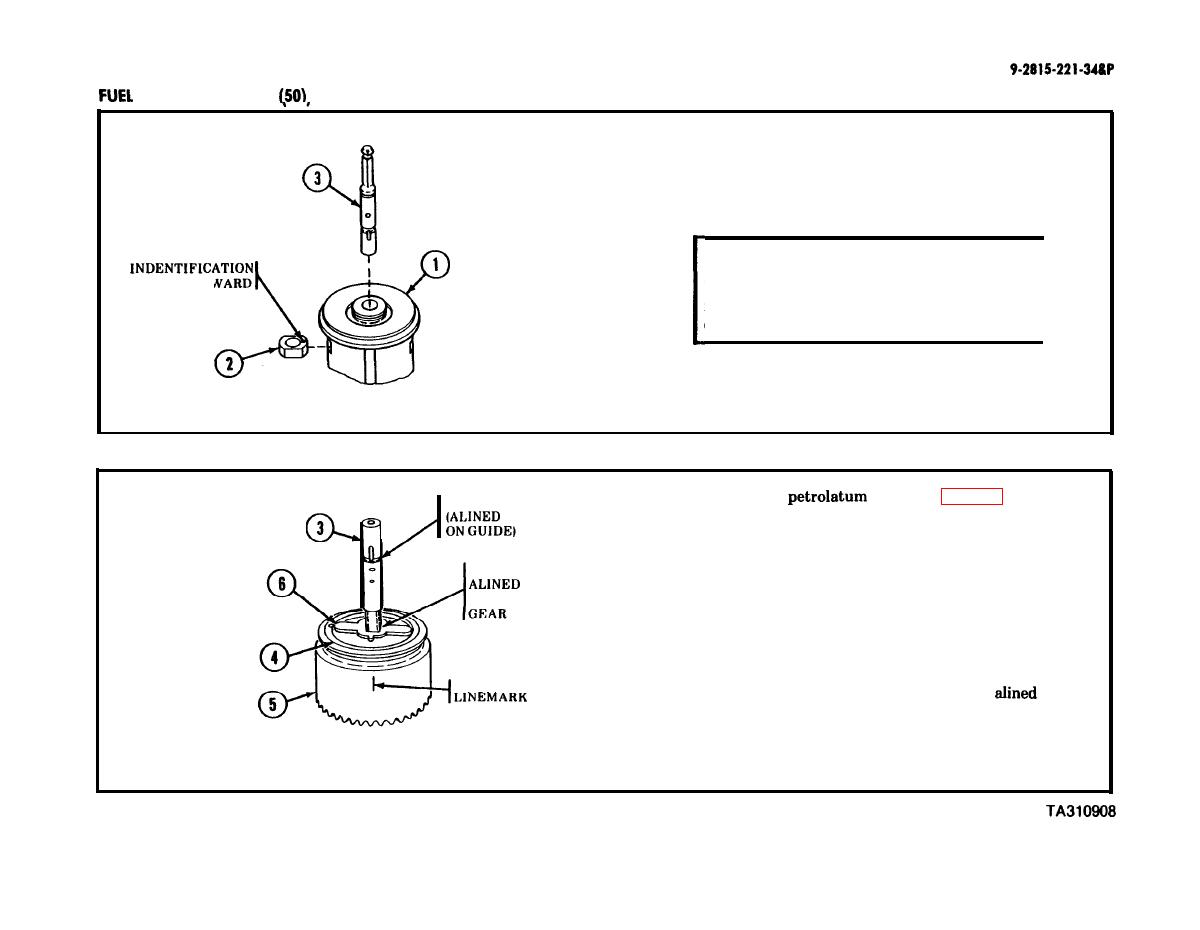

A Invert hydraulic head (1) and place it on a clean workbench.

3

B

Insert metering sleeve (2) into hydraulic head (1) with the

identification dot on the sleeve facing upward.

CAUTION

1

I

DOT UPWARD

Do not use force when inserting plunger. Slight

relocation of metering sleeve is normally required

during insertion.

I

--

2

c

Insert plunger (3) through the lower head bore and plunger

sleeve bore.

D Apply thin film of

(item 25, Appx C) to thrust

DISTRIBUTION SLOT

washer (4) and assemble to face gear (5).

WITH TAB

NOTE

TAB ON GUIDE

Verify that plunger guide (6) fits properly into

WITH

NOTCH IN FACE

mating slot in face gear (5) with stamped letters

of guide facing up. Then remove guide (6) from

gear (5).

E

Assemble plunger guide (6) to plunger with stamped letters

FACE GEAR

facing plunger top, and with tab of guide

with

plunger distributor slot. Position face gear (5) and thrust

washer (4) over end of plunger (3) and make sure that

plunger guide (6) is alined with seats in mating slot in face

gear (5).

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |