|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

*TM 9-2815-213-34

engine horsepower (288 H.P.) ] capacity is insufficient,

testing procedure must b modified to prevent damage to

the dynamometer

a. Using proper lifting device, place engine on

dynamometer test stand.

b. Position engine on the front engine support and

preselected risers for the rear engine supports; secure

engine mounting pads to engine support risers with bolts,

lockwashers and nuts. Remove lifting device.

c. Position dynamometer driveshaft flange to

engine flywheel. Use proper flywheel adapter flange to

match flywheel cap screw holes.

d. Check for proper alignment.

(1) If direct or flexible drive coupled, place a

dial gage holding fixture on face of flywheel housing and

dial gage on adapter flange hub; bar engine over to

obtain measurement. Relocate flange hub on flywheel

as needed and retighten cap screws. Flywheel adapter

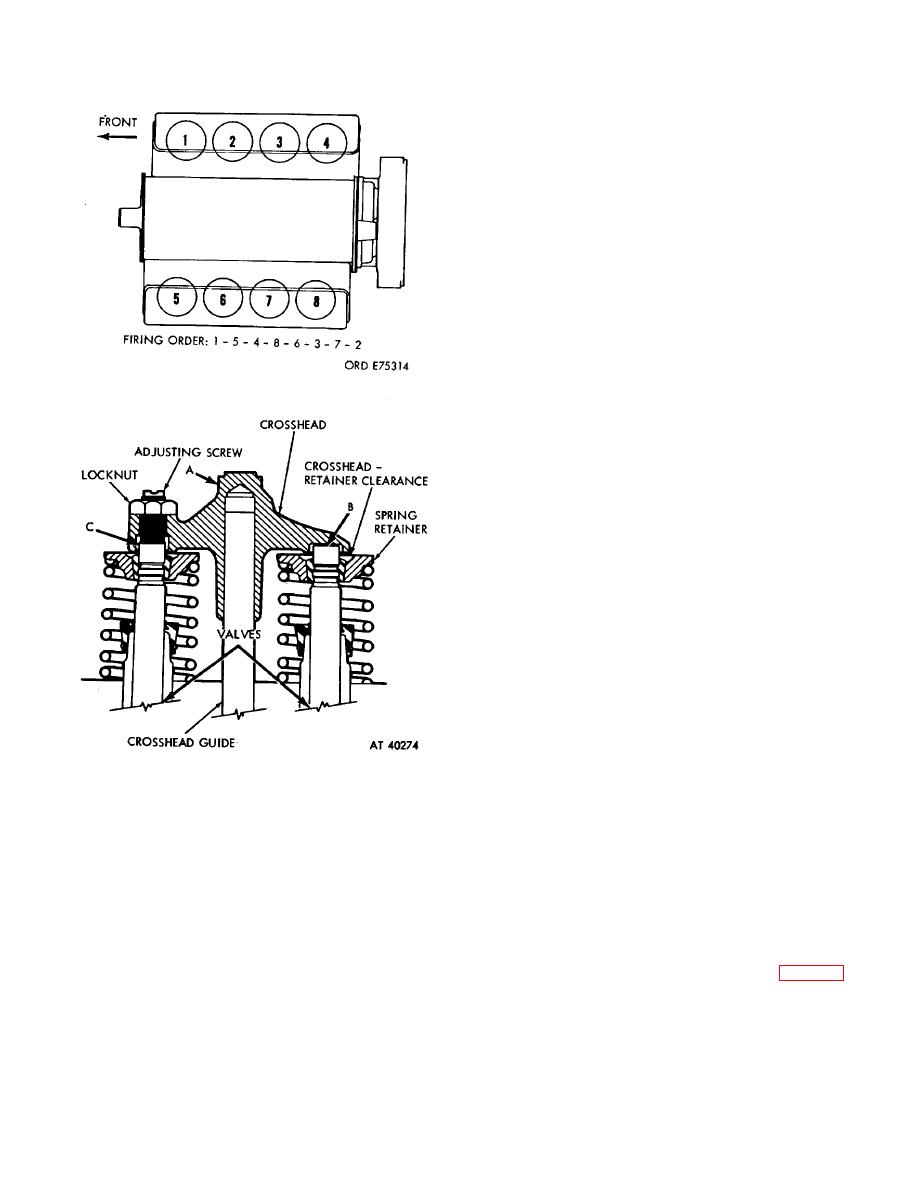

Figure 3-96. Engine firing order.

flange must be con- centric to flywheel and flywheel

housing within 0.005 inch total run-out. When using a

direct coupled dynamometer, a reading must be taken

from face of flywheel housing to outer edge of

dynamometer drive flange. It must not exceed 0.005

inch total run-out when barring dynamometer one

complete revolution.

(2) If universal drive coupled, flywheel and

dynamometer drive flanges must be concentric within

0.005 inch run-out; reading to be taken as above. Install

engine so that centerline of engine crankshaft and

centerline of dynamometer drive shaft are, by design,

out of plane either horizontally or vertically from 1/4 inch

minimum to 1/2 inch maximum. True alignment will

cause universal bearing failure. Secure flywheel to drive

flange with lockwashers and cap screws.

e. Connect water supply and return hose to the

water cooling arrangement.

f. Attach fuel pump return line, if used.

g. Attach fuel supply line to fuel pump suction

connection.

h. Connect electrical connections to starting motor

if motor is used for starting. If another means of starting

Figure 3-97. Crosshead adjustment.

is used make necessary connections.

i. Connect throttle linkage and all instruments

essential because it provides an operating period during

which are included on the control panel of the particular

which coving parts acquire their finish and mating

dynamometer being used.

surfaces reach a full seat. Engine testing helps detect

j. Connect exhaust piping to engine exhaust

possible assembly errors an the need for adjustments as

manifold.

engine "breaks-in as well as establishing a period for

k. Connect air intake piping to air intake manifold.

final adjustments for best engine performance.

A

Use a standard air cleaner approved for the V8300

dynamometer provides the simplest and most accurate

engine.

tool for testing and breaking in an engine. (Follow the

l. Connect a full flow lubricating oil filter to remove

instructions in sequence below for pr starting checks,

any entrapped dirt or grit.

dynameter mounting,

engine starting,

testing,

m. Install a Blow-By Checking Tool (3, fig. B-28) to

adjustments and break-in.

the crankcase breather with adapter.

3-169. Dynamometer Test

Check the capacity of the dynamometer. The stand

must be capable of testing at 96 percent c maximum

3-59

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |