|

|||

|

|

|||

|

Page Title:

Chart 3-2. Troubleshooting Fuel Pump |

|

||

| ||||||||||

|

|

*TM 9-2815-213-34

properly seat 'or that correct spring is installed.

(g) If pressure is low add shims below the

governor weight assist plunger (fig. 3-92) in the governor

weight carrier.

(h) If pressure is high, remove shims.

NOTE

If shims are added or removed recheck

pump calibration.

(i) Reduce Speed to 500 rpm and press

"STOP" button.

(j) Close pump solenoid valve by turning

manual override knob fully counterclockwise.

3-108. Fuel Pump Troubleshooting with Test Stand

corrective actions applicable to the PT (type G) fuel

pump that can be determined and corrected with the use

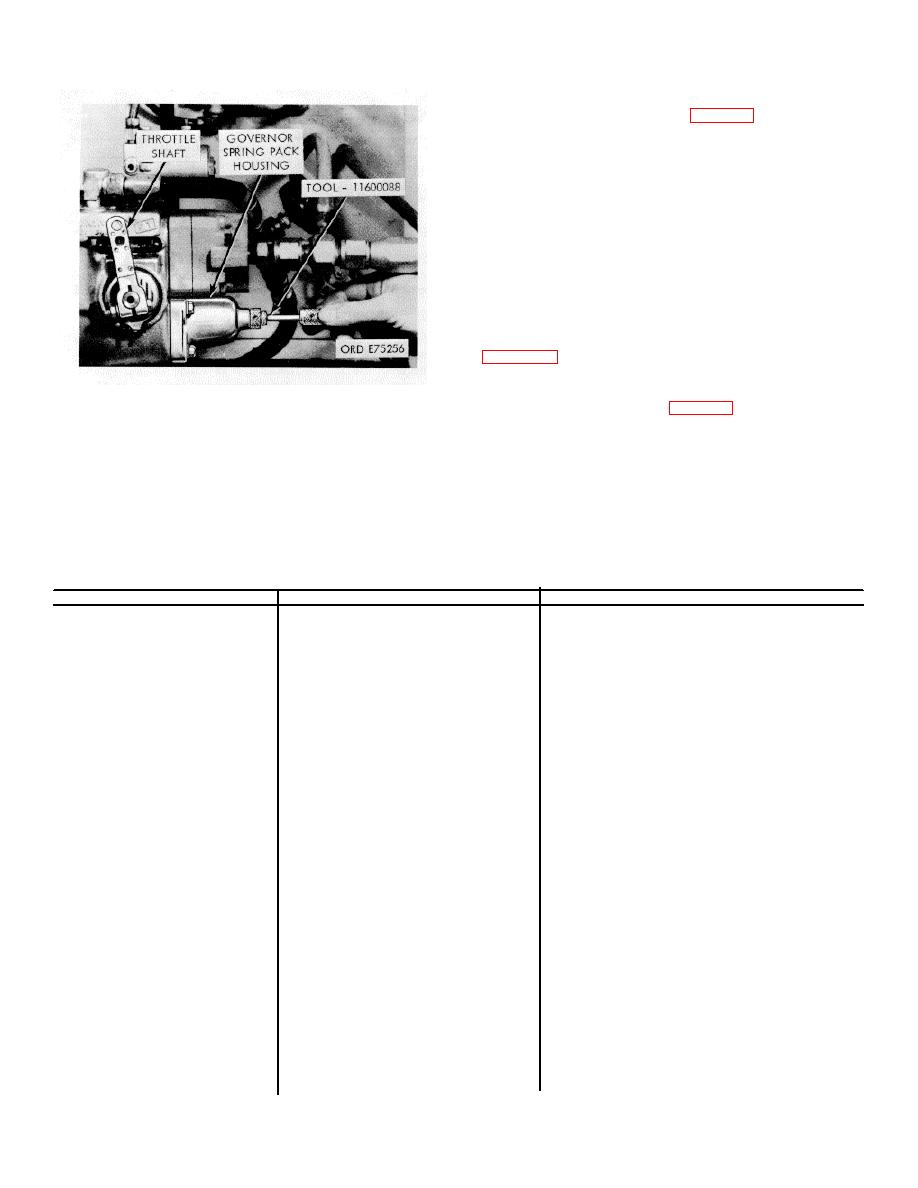

Figure 3-94. Idle speed setting.

of the fuel pump test stand (fig. 3-80).

flow to 140 p.p.h.

Pressure gage should read 46-45

3-1 09. Installation

p.s.i.

Refer to paragraph 210.1., and reverse procedures for

the installation of the fuel pump and

NOTE

fuel lines.

If check point tests are out of tolerance

perform the following steps.

(f) Check torque spring to insure that spring is

Chart 3-2. Troubleshooting Fuel Pump

Malfunction

Probable cause

Corrective action

FUEL PUMP ASSEMBLY

1. Pump gear will not pick up

a. Openings not sealed correctly.

a.

Seal all openings and use new gaskets where

necessary.

fuel at 450 rpm.

b. Suction connection is not tight or

b. Tighten suction connection or re-

is damaged-

is damaged

c. Idle plunger dirty.

c. Check the face of the idler plunger.

2. Air bubbles and fuel are

a. Front seat leakage.

a. Install new seals in the cover after first removing the

passing through the. flowmeter-

pump from the stand and then remove the front

cover

NOTE

This can be located by covering

the "weep hole" in front cover with high

pressure grease which stops air leak.

b. Suction connection is not tight or

b. Tighten suction connection and

the fitting is damaged.

replace damaged parts.

c. Shutoff valve leaking air. Leakage

c. Replace O-Rings to resume

is either past shut-off override

satisfactory operation.

shaft O-Ring or past main housing O-Rings

3. Governor cannot be adjusted

a. Governor spring incorrect due

a. Replace worn spring.

correctly at breaking point.

either to wear or incorrect spring.

NOTE

b. If speed is lower than specified

"Governor cutoff rpm" on the

b. Incorrect selection of shims positioned

V8300 engine fuel pump is-

between governor spring and retainer

add shims, Conversely to reduce

3020 to 3040 rpm--

speed remove shins.

NOTE

Each 0.001 inch shim will change speed 2 rpm.

3-51

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |