|

|||

|

|

|||

|

Page Title:

Figure 3-38. Valve guide installation |

|

||

| ||||||||||

|

|

TM 9-2815-213-34

(2) Ream crosshead guide bore to 15/82 inch if

CAUTION

necessary after installation.

Insure that the 1/16 inch hole in valve

c. Injector Sleeves.

guide is turned toward exhaust manifold

(1) Install injector sleeves using sleeve driver

and that the hole remains open after

(14, fig. B-28) as shown in figure 3-40.

assembly.

(2) Remove injector sleeve driver and install

injector sleeve holder (fig. 3-30).

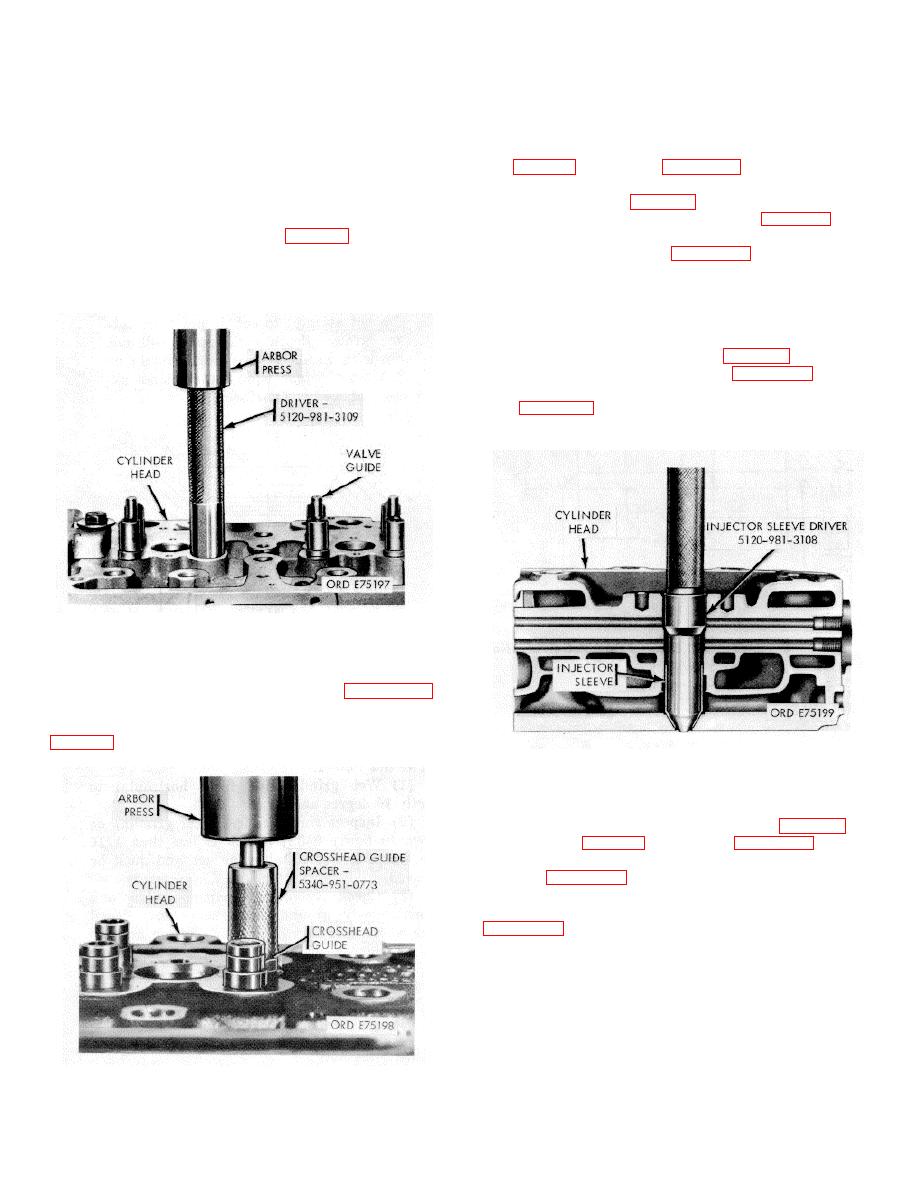

(1) Install valve guides as shown in figure 338.

(3) Using sleeve expander (13, fig. B-28), roll

Press in valve guide to 0.695/0.710 inch above head

upper portion of injector sleeve to 1.145/1.155 inches

surface with valve guide driver (49, fig. B-28).

inside diameter as shown in figure 3-41.

(2) Ream valve guide from bottom side of

NOTE

cylinder head using reamer, drill press and floating tool

holder. Valve guide must have inside diameter of

Set drill press at 250 rpm and 600

0.4525/0.4532 inch after reaming.

pounds pressure for 30 seconds; apply

OE-10 oil during operation.

(4) Remove injector sleeve holder.

(5) Using sleeve roller (16, fig. B-28), roll lower

portion of injector sleeve as shown in figure 3-48.

(6) Cut injector sleeve seat with sleeve cutter

(17, fig. B-28) as shown in figure 343, to provide

maximum allowable sleeve protrusion of 0.125 inch,

0.100/0.115 inch nominal.

Figure 3-38. Valve guide installation

b. Crosshead Guides.

(1) Install crosshead guides as shown in figure 3-39.

Press in crosshead guide to 2.090/

2.110 inches above head surface with guide spacer (47,

Figure 3-40. Injector sleeve installation.

d. Valve Seat Inserts.

(1) Recondition valve seat counterbore using tool

kit, cutter, and valve guide (48, 51 and 41, fig. B-28) to

proper size (A, fig. 3-36), as shown in figure 3-44.

(2) Install swirl plate in intake valve ports only as

shown in figure 3-45.

(3) Install valve seat insert using valve seat insert

tool kit and peen insert in cylinder head as shown in

e. Grind Valve Seats.

(1) Select a suitable valve grinding machine

Figure 3-39. Crosshead guide installation.

3-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |