|

|||

|

|

|||

|

Page Title:

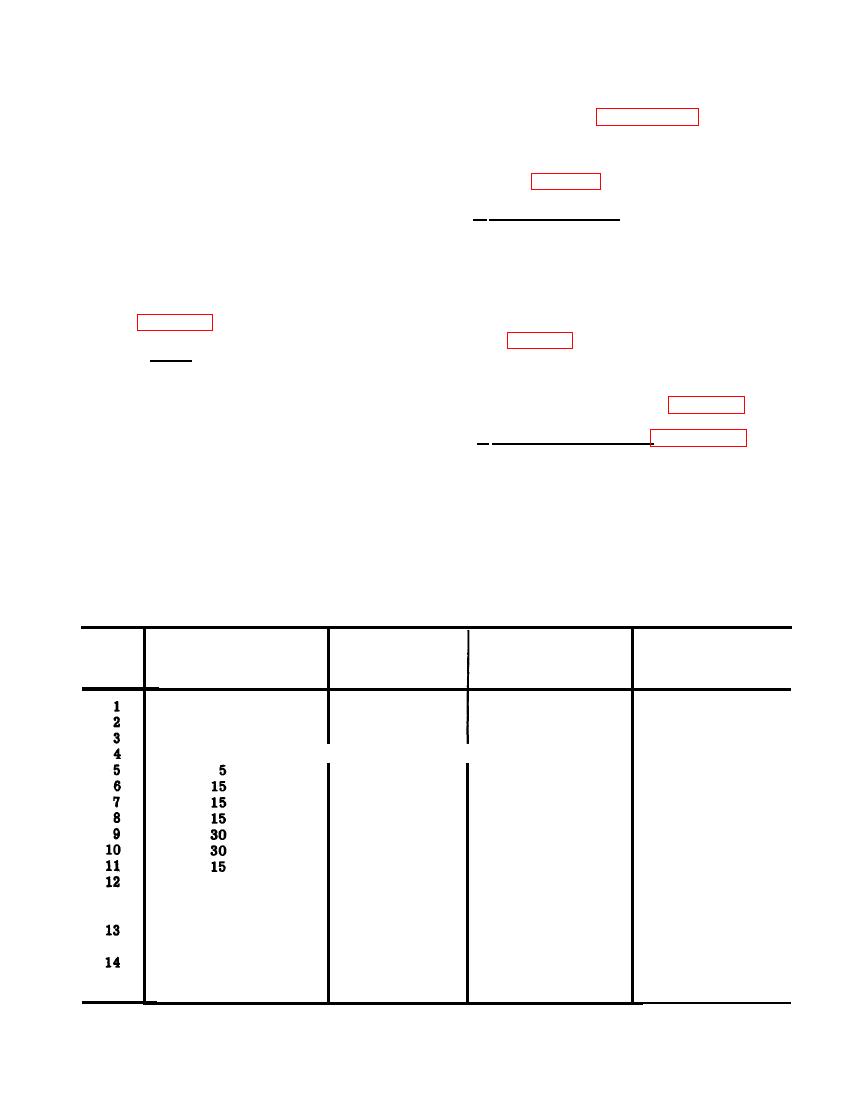

Table VI. Run-in Schedule (Long) |

|

||

| ||||||||||

|

|

(3) Place fuel shutoff in "ON" position.

heads must be retightened to a torque of 130

pound feet. Refer to paragraph 94h(l) through

(4) Start engine by operating electric start-

(8), for procedures. Retightening cylinder head

ing motor with the throttle depressed

nuts after engine warmup is important before

25 percent.

continuing with the engine run- in schedules,

outlined in Tables VI and VII.

(5) Engine oil pressure should register at

least 15 psi with cold oil within 30

e. Run-in Schedules. A rebuilt engine should

seconds of starting. If pressure has

be started and run-in in accordance with one of

not reached 15 psi within 30 seconds,

the following procedures.

STOP THE ENGINE IMMEDIATELY by

holding the fuel shutoff in the "OFF"

(1) When any of the original bearings or

position. Determine the cause of low

piston rings have been replaced and

oil pressure. Refer to troubleshooting,

the cylinder liners rehoned, during

rebuild, use the long run- in schedule,

Note. After starting engine, run at

idle (650-700 rpm) for five minutes to

(2) When original bearings and rings were

permit the engine to warm up, and to

re-installed during rebuild, use the

properly circulate oil and coolant.

short run- in schedule, Table VII.

d. Retorque Cylinder Head Nuts. After the

f. Performance Curve. Figure 513 gives

engine has been started and has run approxi-

typical performance curves for three types of

mately 20 minutes at 1200 rpm, the cylinder

fuel.

Note. The long run-in schedule is for rebuilt engines in which new bearings and piston rings

have been installed or the cylinder liners rehoned. Install engine in combination with a dynamome-

ter or other variable loading device and operate in accordance with following schedule.

Gross brake

Duration

Period

Fuel

(bare engine)

(minutes)

Engine Speed

Diesel

650-700

0

5

15

1000

Diesel

5

15

1200

Diesel

10

Shutdown and retorque all cylinder head nuts to 130 pound feet.

.

650

Diesel

Idle

15

Diesel

1000

15

Diesel

1200

1600

33

Diesel

64

2000

Diesel

110

Diesel

2400

140

2600

Diesel

2600

140-145

Diesel

(Adjust full throttle

position and set

governor)

92 minimum

1400

Diesel

Power check (full

throttle)

Diesel

o

650-700

(Set idle adjust-

ment)

329

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |