|

|||

|

|

|||

|

Page Title:

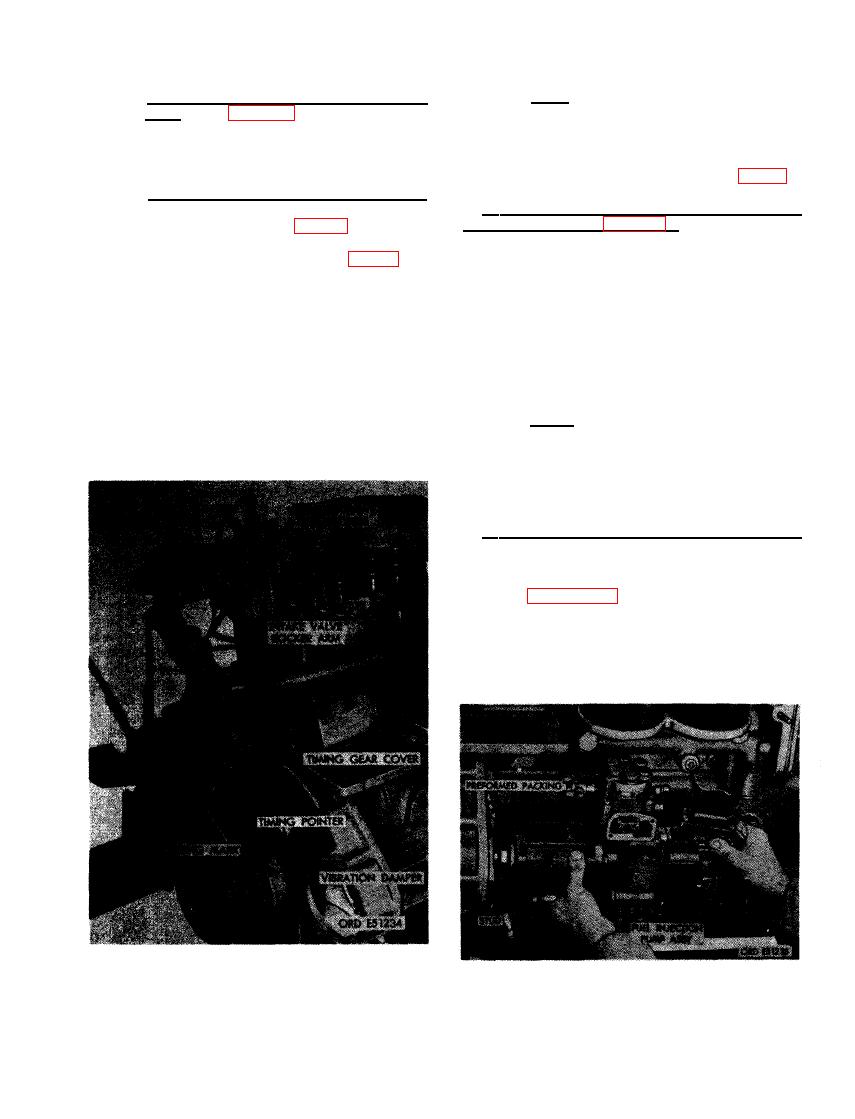

FIGURE 494. CHECKING ENGINE TIMING PRIOR TO FUEL INJECTION PUMP INSTALLATION. |

|

||

| ||||||||||

|

|

Note. The injection pump camshaft and

(4) Install fuel injection pump driven gear

plunger spring assembly pressure tends

h u b . Refer to figures 72 and 73 and re-

to prevent timing mark on hub from re-

verse the sequence of instructions to

maining in line with its mating pointer.

install the fuel injection pump driven

These marks must be alined when instal-

gear hub.

ling injection pump driven gear (fig. 77).

(5) Timing fuel injection pump assembly.

b . Check Engine Timing Before Installing

T h e timing mark on the automatic

Fuel Injection Pump (fig. 494).

advance unit hub (fig. 64) must be

alined with pointer when the marked

(1) Rotate crankshaft clockwise, as viewed

tooth in the timing window (fig. 65) is

from fan end, until cylinder No. 1 intake

visible. It is possible to have the tim-

and exhaust valves are closed. When

ing marks in the advance unit alined

valve clearance is evident at both rocker

and not have the marked tooth on the

arms, both valves are closed.

plunger drive gear in the timing window

visible. When the marked tooth is visible

(2) The timing mark on the vibration dam-

and the advance unit marks are alined,

per and pulley assembly must be alined

the pump is properly timed. If the

with the pointer on timing gear cover.

marked tooth is not visible, rotate the

gear hub 360 degrees, in either direc-

tion, so the timing marks do aline. This

N o t e . The engine is properly timed

insures proper timing when the pump is

when timing mark on the vibration

installed on the engine.

damper is alined with pointer on timing

gear cover and cylinder No. 1 is on the

compression stroke (both intake and

exhaust valves closed).

c . Install Fuel Injection Pump Assembly.

Install the fuel injection pump assembly as

follows.

(1) Figure 495. (A) Timing marks of fuel

injection pump assembly and vibration

damper must remain alined as pump is

installed on engine, Use new preformed

packing if original pump is installed on

engine. New pump assemblies include

PRIOR TO FUEL INJECTION PUMP

INSTALLATION.

PUMP ASSEMBLY.

315

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |