|

|||

|

|

|||

|

Page Title:

Section II. ASSEMBLY OF ENGINE FROM SUBASSEMBLIES |

|

||

| ||||||||||

|

|

Section II. ASSEMBLY OF ENGINE FROM SUBASSEMBLIES

Note. Upper main bearing sleeve halves are

BLY AND PISTON COOLING NOZZLES

property installed when number on bearing tab

corresponds to number on main bearing cap

a . Preparations. Support the cylinder and

and the number is on camshaft side of engine.

crankcase on suitable blocks, with the cylinder

head mounting surface resting on the blocks.

a n d reverse seauence of instructions to install

b. Camshaft Assembly. Refer to figure 310

crankshaft assembly.

and 311 and reverse the sequence of illustra-

tions to install camshaft assembly and thrust

plate.

Note. The camshaft rear bearing plug should

a . Install Main Thrust Bearing Cap. Install

not be installed until after the camshaft end play

main thrust bearing cap, with assembled lower

is established (par. 261).

sleeve bearing, in center (No. 4) position.

Install two 19/32-inch x 3/16-inch thick flat

c . Piston Cooling Nozzles. Figure 465. (A)

washers and 9/16 x 5- 1/16 cap screws to se-

Install piston cooling nozzle. (B) Secure piston

cure thrust bearing cap. Do not tighten the cap

cooling nozzle by installing 5/16-inch plain nut.

screws more than is necessary to keep bearing

(C) Install remaining five piston cooling nozzles

cap in position.

in same manner.

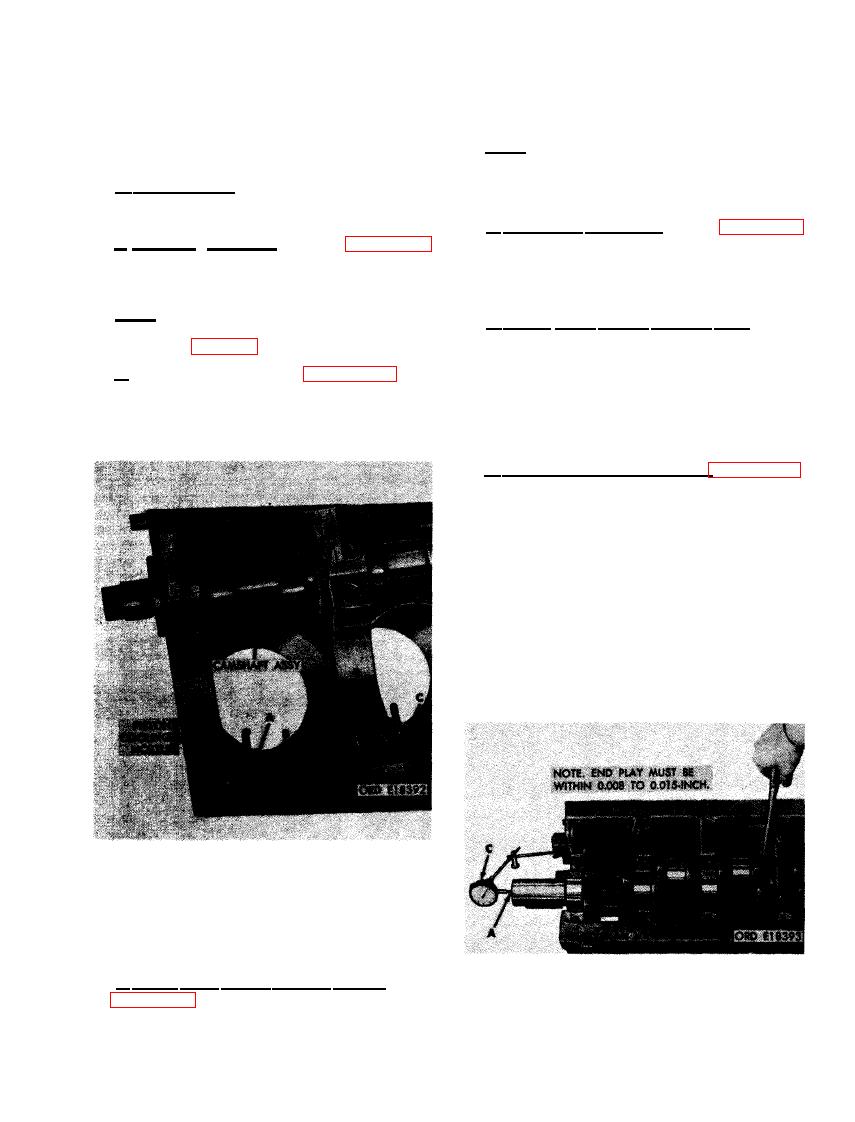

b . Check Crankshaft End Play. Figure 466.

(A) Mount dial indicator on crankcase so in-

dicator point rests on front end of crankshaft

assembly. (B) Using a heavy screwdriver be-

tween center main bearing cap and crankshaft

counterweight, push crankshaft toward rear end

of cylinder and crankcase to aline thrust bear-

ing flanges. Tighten main bearing cap screws to

a torque of 1100 pound inches. (C) Set indicator

on zero reading ("O"). (D) Using heavy duty

screwdriver, push crankshaft toward f rent end

of cylinder and crankcase to check end play.

Crankshaft end play must be within 0.008 to

0.015-inch.

NOZZLE.

BEARINGS AND CRANKSHAFT ASSEM-

BLY

a. Upper Matn Sleeve Bearing Halves. Refer

to figure 308 to install the upper main sleeve

bearing halves in cylinder and crankcase.

PLAY.

299

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |