|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

251. ASSEMBLY

e. Adjust Height of Release Levers. Adjust

height of release levers as follows.

a. Install Release Lever Needle Rollers and

Yokes. Figure 460. (A) Coat 152 needle rollers

with grease (GAA) (MIL-G-10924). Insert 19

release lever needle rollers in yoke pin bore

in release lever, using one bearing retaining

pin to hold rollers in position as they are in-

stalled. (B) Install yoke, guiding yoke pin through

needle rollers. Yoke pin must enter needle

roller pack as pin is pushed into position to

push out the temporary bearing retaining pin.

(C) Place head of yoke pin on a flat hard sur-

face and mushroom or split headless end of

yoke pin to prevent pin from working out of

position.

Note. Install the needle rollers and yokes on

the remaining three release levers in the same

manner.

b. Install Release Levers. Coat 19 release

lever needle rollers with grease (GAA) (MIL-

G 10924). Insert the 19 release lever' needle

rollers in release lever pin bore using one bear-

ing retaining pin to hold rollers in position as

they are installed, as shown in figure 454. Refer

to figure 453 and reverse the sequence of in-

structions to install the four release lever and

yoke assemblies on the pressure plate.

Note. Spread or split headless end of release

lever pins to prevent them from working out

of position.

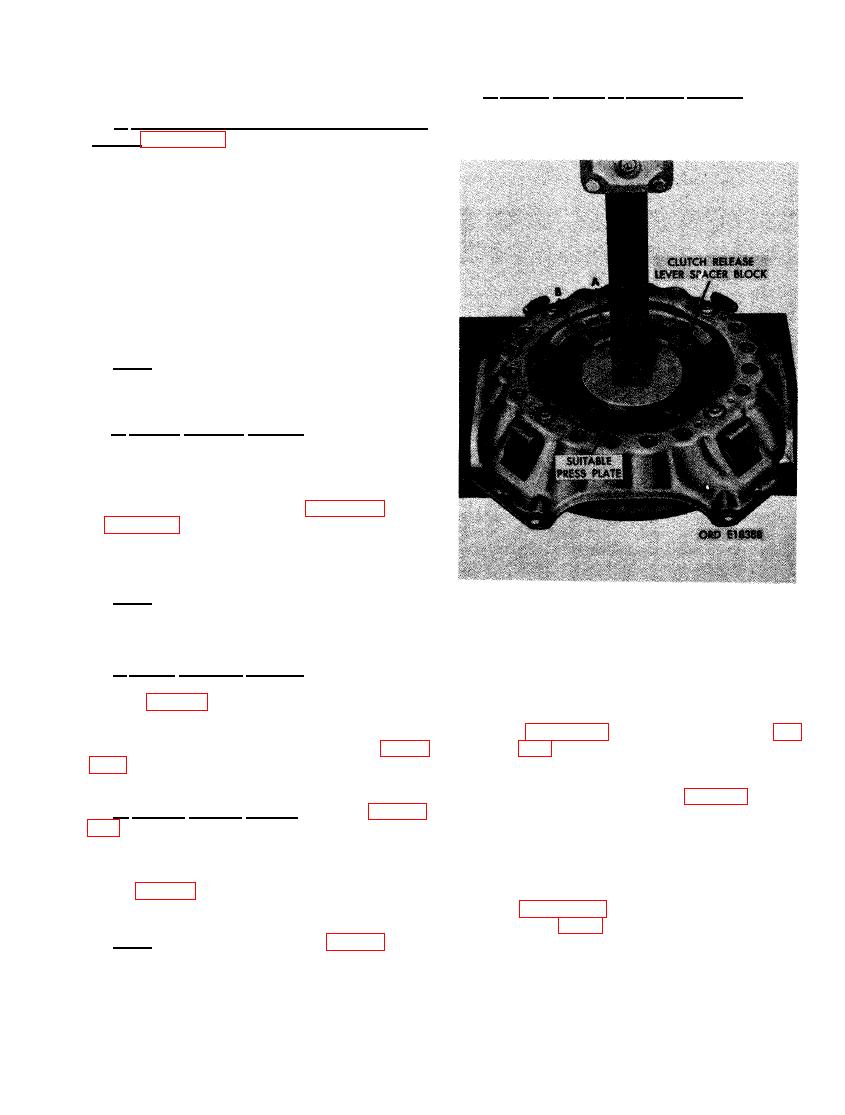

LEVER SPACER BLOCKS BEFORE RE-

LEASE LEVER HEIGHT ADJUSTMENT.

c. Install Pressure Springs. If pressure plate

has been resurfaced, install 1/32- inch thick

spacers (fig. 447) under pressure springs for

each 1/32- inch removed from the pressure plate

(1) Figure 461. (A) Remove cross bar (fig.

surface. The spacers will be necessary in main-

taining original spring tension. Refer to figure

on throw-out bearing contact surface of

to install pressure springs.

release levers. The use of press plate,

instead of cross bar (fig. 451), will

allow more release lever travel for

d. Install Clutch Cover. Refer to figures

clutch release lever spacer block in-

stallation. (B) Install one clutch release

trations and instructions to assemble the clutch

lever spacer block between release

cover and pressure plate assembly. Aline

scribe marks on clutch cover and pressure

lever and clutch cover as shown.

plate (fig. 449) before installing release lever

adjusting nuts.

(2) Figure 462. (A) Position clutch spacer

plate (fig. 34) against clutch cover pres-

Note. Do not install lock plates (fig. 450) and

sure plate clutch facing surface as you

would when positioning driven member

Cap screws until release lever height has been

adjusted.

during clutch installation. (B) Secure

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |