|

|||

|

|

|||

|

Page Title:

Section XVI. REBUILD OF FLAME HEATER FUEL SYSTEM COMPONENTS |

|

||

| ||||||||||

|

|

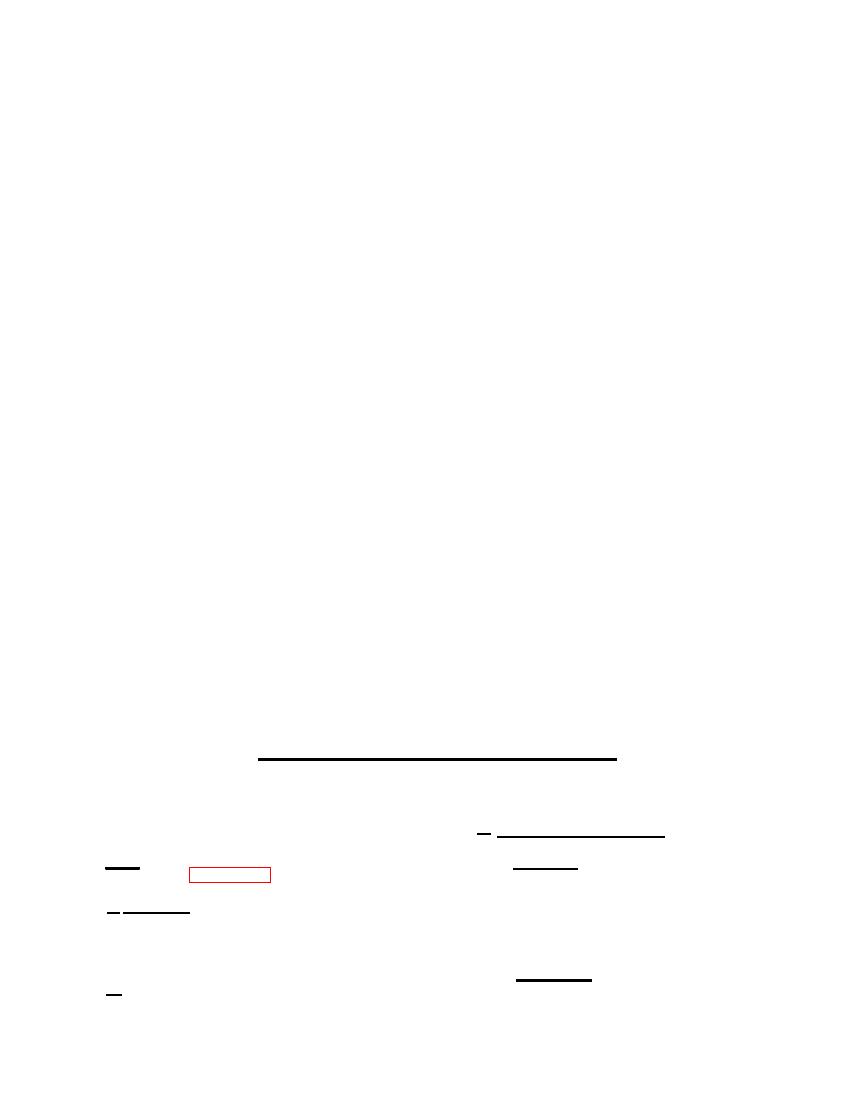

A - Exhaust manifold gasket

l-in. hose clamp (late model engines)

BB

-

B - Exhaust manifold seal

Oil drain hose (late model engines)

CC

-

C - Exhaust manifold center section assembly

3/4-in. hose adapter (late model engines)

DD

-

1- Exhaust manifold center section

EE

-

3/8- in. self-locking nut

1/2- in. tube, 90 degree elbow

2- 3/8 x 1- 3/4 plain stud

FF

-

D - Exhaust manifold front section assembly

1/2- in. tube sleeve

GG

-

1- 1/2-in. pipe plug

1/2- in. sleeve nut

HH

-

2- Exhaust manifold front section

90 degree elbow assembly (early model

JJ

-

E - Intake manifold elbow gasket

engines)

F - Intake manifold elbow assembly

1- 9/16-in. tube nut

1- Elbow

2- 3/8-in. tube sleeve

2- 5/16 x 1-3/8 plain stud

3- 9/16- 18UNF- 2A, 90 degree elbow

G - Flame heater gasket

4- 9/16-in. plain nut

H - [gnition unit clamp

5- 9/16-in. flat washer

J - 5/16- in. lock washer

6- 15/32 id x 5/64 thk preformed packing

K - 5/16- in. plain nut

KK - Turbosupercharger assembly (early

L - Ignition unit

model engines)

M - Ignition lead

LL - Turbosupercharger oil drain hose (early

N - 1/8 pipe x 1/4 tube, 90 degree elbow

model engines)

P - 1/4 x 1/8 pipe bushing

MM - 3/4-in. tube union half (early model

Q - Intake manifold flame heater assembly

engines)

R - Turbosupercharger- to- intake manifold

NN - 90 degree elbow assembly (early model

hose clamp

engines)

S - 3-in. id rubber hose

1- l/4-NPT x 1/2- 18UNF 90 degree elbow

T - 3/8 x 7/8 cap screw (late model engines)

2- 3/8-in. tube sleeve

U - 3/8-in. lock washer (late model engines)

3- 1/2-in. tube nut

V - Oil inlet tube (late model engines)

P P - Turbosupercharger-to- exhaust manifold

W - Oil inlet tube gasket (late model engines)

gasket

Turbosupercharger assembly (late model

QQ - Oil inlet tube (early model engines)

engines)

RR - 7/16- in. self-locking nut

Y - Oil outlet tube gasket (late model engines)

SS - 7/16- in. flat washer

Z - Oil outlet tube (late model engines)

TT - Exhaust manifold rear section assembly

AA- Crankcase breather tube bracket (late

1- 1/2-in. pipe plug

model engines)

2- Exhaust manifold rear section

FIGURE 410. EXHAUST MANIFOLD, FLAME HEATER, AND RELATED

PARTS - EXPLODED VIEW - CONTINUED.

Section XVI. REBUILD OF FLAME HEATER FUEL SYSTEM COMPONENTS

228. SOLENOID VALVES

c. Cleaning and Inspection.

Note. The key letters shown below in paren-

(1) Cleaning. Plug valve inlet and outlet

theses refer to figure 411.

openings to prevent entrance of foreign

material. Clean the solenoid valves

a. Removal. Remove four No. 10 x 1 machine

with a cloth moistened with dry-cleaning

s c r e w No. 10 lock washers (S) and re-

solvent. The valves contain rubber parts

move two solenoid valves (CC) from the flame

and should not be immersed in solvent.

heater fuel pump and fuel filter bracket.

(2) Inspection. Inspect the solenoid valves

for cracks and dents. Install suitable

b. Disassembly. Remove three elbows (BB-

fittings, actuate solenoid valve with 24

1) from solenoid valves (CC).

263

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |