|

|||

|

|

|||

|

Page Title:

Section XII. REBUILD OF OIL FILTERS, OIL COOLER AND OIL FILTER HOUSING, AND OIL COOLER |

|

||

| ||||||||||

|

|

Section XII. REBUILD OF OIL FILTERS, OIL COOLER AND

OIL FILTER HOUSING, AND OIL COOLER

210. OIL FILTERS

related parts in the same manner as described

in steps A through D, above. (F) Remove two

Note. The key letters shown below in paren-

3/4- inch pipe plugs. (G) Remove 3/8- inch pipe

these refer to figure 402 except where other-

plug.

wise indicated.

a . General. Both oil filters are identical.

For instructional purposes only one oil filter

will be overhauled.

b. Disassembly. Remove the sealing cup

(A-5) and retaining spring (A-4) from the bar

(A-1). Pull bar out of filter case (A-3) and

discard washer (A-2).

--. Cleaning and Inspection.

c

(1) Cleaning. Clean the filter case (A-3)

and related parts as directed in para-

graph 152 c.

(2) Inspection. Inspect the filter case (A-3)

for dents and damaged gasket surfaces.

Inspect bar (A-1) for cracks, damaged

threads, and damaged gasket surfaces.

Examine the retaining spring (A-4) for

cracked and set condition.

d. Repair. Repair minor damage to filter case

(A-3) and bar (A-1). Gasket surfaces may be

resurfaced using crocus cloth placed on a flat

BYPASS VALVE PLUNGERS AND PIPE

s u r f a c e . Replace filter case and bar when

PLUGS.

cracked, distorted, or when gasket surfaces

cannot be repaired. Replace the retaining spring

(A-4) when cracked or in a set condition.

b. Cleaning and Inspection.

e. Assembly Position new washer (A-2) on

(1) Cleaning. Clean the housing (B-2) and

related parts as directed in paragraph

bar (A-1) and insert bar into filter case (A-3).

'

Position retaining spring (A- 4) and install seal-

152 c.

ing cup (A-5) on bar.

(2) Inspection. Inspect the housing (B- 2) as

directed in paragraph 153 b. Inspect the

helical coil inserts (B- 1) as directed in

Note. The key letters shown below in paren-

theses refer to figure 402 except where other-

B-5) as directed in paragraph 153 d .

wise indicated.

Check the bypass valve plungers (M and

W), housing (B- 2), and valve plunger

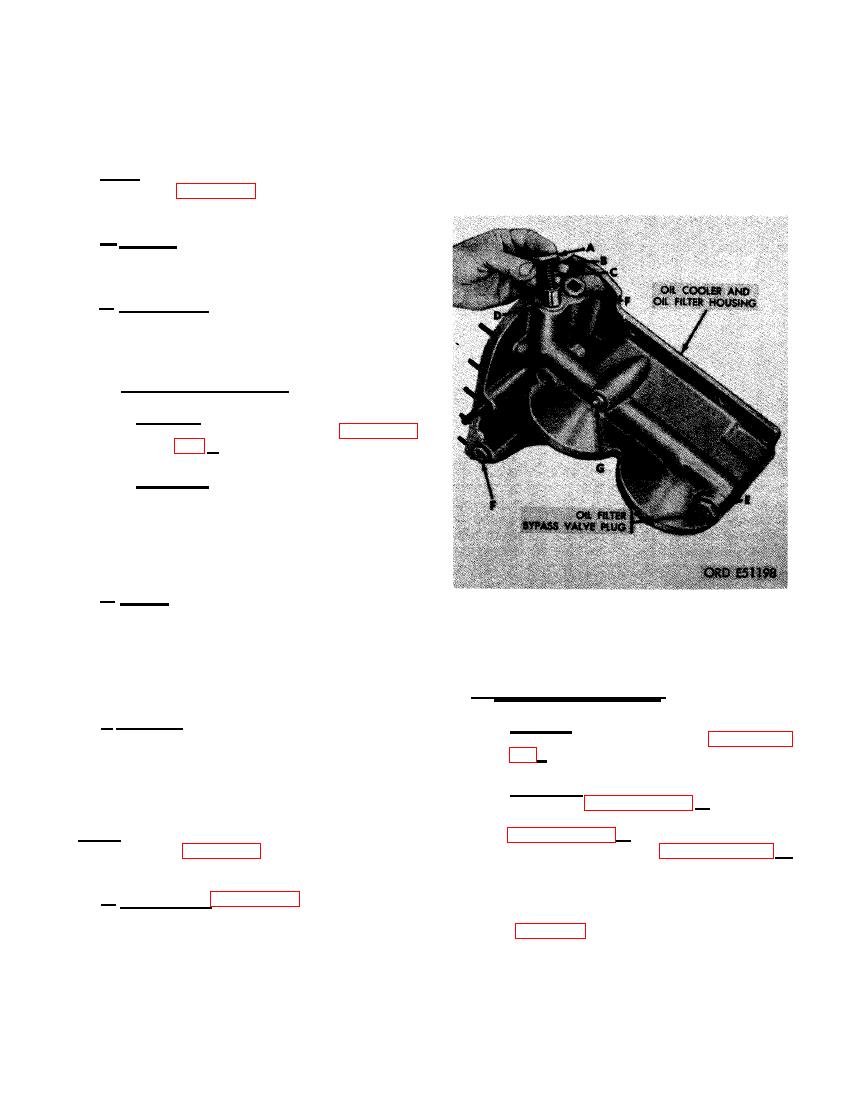

a. Disassembly. Figure 403. (A) Remove oil

springs (Q and U) against limits spec-

ified in repair and rebuild standards

cooler bypass valve plug from oil cooler and

oil filter housing. (B) Remove and discard oil

plungers and plunger bores in the hous-

cooler bypass valve plain washer (gasket). (C)

ing for scratches and wear patterns.

Remove oil cooler bypass valve plunger spring.

Inspect valve plunger s p r i n g s for

(D) Remove oil cooler bypass valve plunger.

cracked and set condition.

(E) Remove the oil filter bypass valve plug and

251

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |