|

|||

|

|

|||

|

Page Title:

Section IX. REBUILD OF VALVE ROCKER ARMS, SHAFTS, PUSH RODS, TAPPETS, AND RELATED CYLINDER HEAD PARTS. |

|

||

| ||||||||||

|

|

are damaged. Grind slightly pitted or

burned valves that do not seat perfectly

to limits specified in figure 387. Re-

place valves that cannot be ground to

these limits. Check valve length from

seat contact to tip of stem after grinding

as shown in figure 387. Replace valve

if length is not within limits specified

in repair and

r e b u i l d standards

(2) Valve springs. Replace inner spring

(K-3) and outer spring (K-4) when

worn, cracked, or other-wise damaged.

Replace springs that do not meet limits

specifed in repair and rebuild stan-

dards (par. 294).

(3) Valve spring retainers. Replace worn

or cracked valve spring retainer (K-2).

(4) Valve rotators. Replace valve rotators

(K-5) when inner section does not rotate

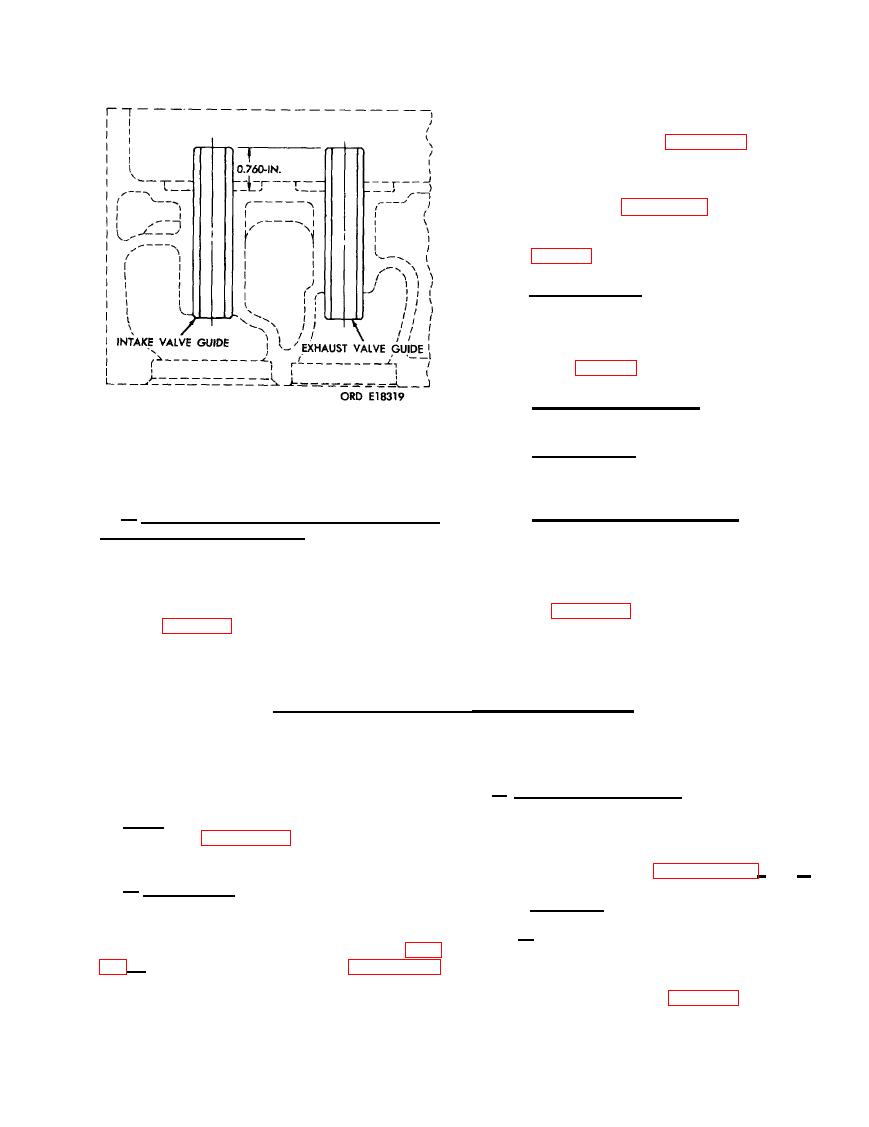

SETTING HEIGHT OF VALVE GUIDES IN

freely, or when it is worn or cracked.

CYLINDER HEAD.

(5) Valve spring retainer locks. Replace

b. Valves, Springs, Retainers, Rotators, and

v a l v e spring retainer lock (K-1) if

Valve Spring Retainer Locks.

worn or cracked.

(1) Valves. Replace warped intake valves

201. ASSEMBLY

(K-14) or exhaust valves (K-13) or

valves which do not meet limits spec-

ified in repair and rebuild standards

Refer to figures 380 through 384 and re-

verse the sequence of illustrations and instruc-

pitted or burned faces. Replace valves

tions to assemble the front cylinder head. As-

having badly pitted, scored, or scratched

semble the rear cylinder head in the same

stems. Replace valves if locking grooves

manner.

Section IX. REBUILD OF VALVE ROCKER ARMS, SHAFTS, PUSH RODS,

TAPPETS, AND RELATED CYLINDER HEAD PARTS.

b. Cleaning and Inspection.

Note. The key letters shown below in paren-

(1) Cleaning. Clean six valve rocker arms

these refer to figure 385 except where other-

(C), rocker arm shaft (E), three rocker

wise indicated.

arm supports (F) and two thrust springs

(J) as directed in paragraphs 152 c and d.

a . Disassembly. The front and rear sets of

valve rocker arms are identical and interchanEe-

(.2) .Inspection.

.

able. For instructional purposes, the front set

of valve rocker arms will be disassembled.

(a) Inspect valve rocker arm assemblies

(C) for cracks using a magnifying

Disassemble the front set of rocker arms (par.

glass and strong light. Check bearing

through 186. Disassemble the rear set of rocker

against limits specified in repair and

arms in the same manner.

rebuild standards (par. 294). Inspect

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |