|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

yoke assembly, flat washer. and plain nut as

outlined in c, above. Tighten plain nut until all

parts are seated and alined. Apply a light

coating of engine oil OE-10 (MIL-0-2104) on

outside diameter of bearing. Oil hole in bearing

must be alined with grease pencil mark made

in b, above. Slowly tighten plain nut until bear-

ing is pulled into bore and flush with front

edge. Use a suitable pin through hole in the

threaded end of the shaft to keep it from turning

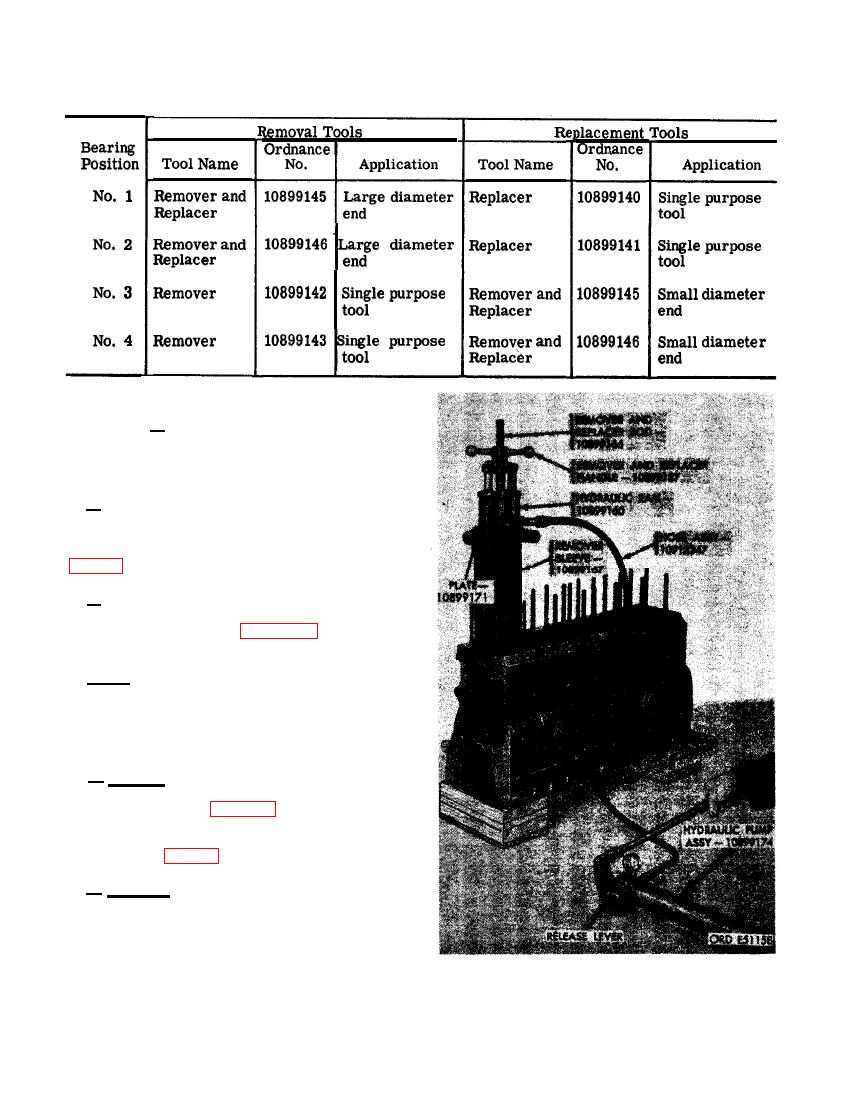

f . Installation of remaining bearings will

be similar to the above. Select proper remover

and/or replacer from Table IV and install

bearings.

Note. Replacement camshaft bushing-type

bearings are finished to size and do not need

machining after installation.

a . General. Replace cylinder liners which

do not meet requirements specified in repair

and rebuild standards (par. 292). When neces-

sary to replace cylinder liners use remover

and replacer kit - 8722925 and hydraulic ram

kit - 10912249 (figs. 24, 330, and 331).

b. Removal.

(1) Assemble remover and replacer rod -

10899166 and remover shoe - 10899168

and secure with clevis pin - 96906-

20392-10-73 and cotter pin - 96906-

24665-375.

LINER.

202

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |