|

|||

|

|

|||

|

Page Title:

REPAIR OF CYLINDER AND CRANKCASE AND MISCELLANEOUS ITEMS |

|

||

| ||||||||||

|

|

Note. Check lower main thrust sleeve

bearing half in bore of thrust bearing

of the main bearings with a dial in-

cap in the same manner.

dicator as shown, and against limits

specified in repair and rebuild stan-

(12) Check main bearing bores. Apply a thin

dards (par. 292). Replace bearing

coat of Prussian blue to backs of upper

halves not meeting the repair and re-

and lower bearing halves. The blue

build requirements. Remove the main

transfer will show bearing contact area

bearing caps and bearing halves from

in crankcase bore. Check main bearing

the crankcase and check the contact

bores as follows.

surface as indicated by Prussian blue

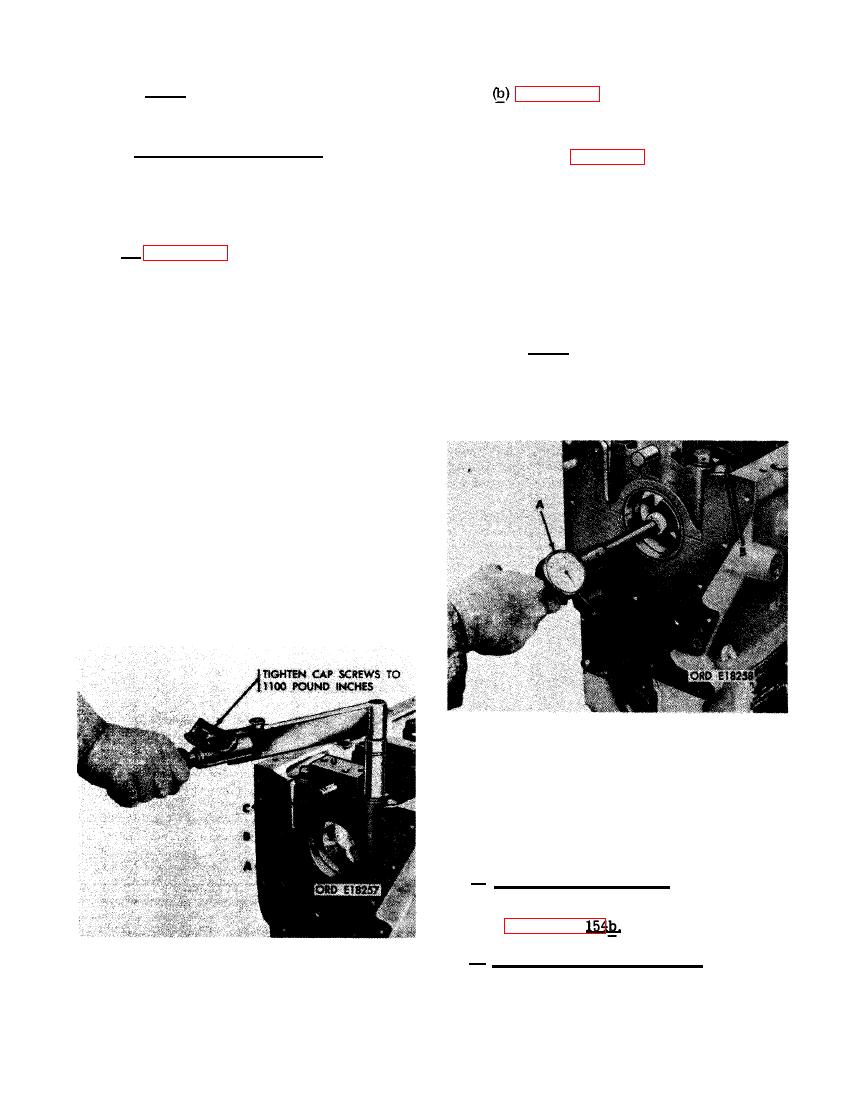

(a) Figure 326. (A) Install the remaining

transfer. Replace bearing halves that

do not make 75 percent contact with

six upper main sleeve bearing halves

in their original location in bearing

crankcase bearing bores and recheck

new bearings. (B) Check the remaining

bore of cylinder and crankcase. Install

bearing bores in the same manner.

the remaining six lower main sleeve

bearing halves in their respective

Note. After main bearing bores have

bearing caps. (B) Apply a light coating

of engine oil OE-10 (MIL-0-2104) to

been checked, remove all main bearing

the edges of the seven main bearing

caps and bearing halves from cylinder

caps with sleeve bearing halves in-

and crankcase.

stalled. Install bearing caps with bear-

ing halves in their proper location in

the crankcase, according to the loca-

tion numbers stamped on the cap. The

location numbers appear on the cam-

shaft side of the cap. (C) Apply a small

amount of mica-base antiseize com-

pound (MIL-A-13881) to the threaded

area of each main bearing cap screw.

Install two plain washers and cap

screws through each main bearing cap.

Tighten each pair of cap screws al-

ternately to a final torque of 1100

pound inches as shown.

WITH SLEEVE BEARINGS HALVES IN-

STALLED USING A DIAL INDICATOR.

AND MISCELLANEOUS ITEMS

a. Cylinder and Crankcase. Repair cylinder

and crankcase and main bearing caps having

nicks, burs, and raised metal surfaces as out-

lined in paragraph

b . Main Sleeve Bearing Halves. Repairs to

the main sleeve bearing halves are limited to

BEARING CAP SCREWS PRIOR TO MAIN

replacement of unserviceable bearings.

BEARING BORE CHECK.

199

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |