|

|||

|

|

|||

|

Page Title:

CHECKING NOZZLE OPENING BREAK PRESSURE AND SPRAY PATTERN |

|

||

| ||||||||||

|

|

b. Install Injector Nozzle and Holder Assem-

bly-in Tester. Install nozzle and holder assembly

on the fuel injector nozzle tester (par. 83c) and

perform tests outlined in paragraph 83d. -

--

c. Repair and Replacement. Repair or re-

place defective nozzles as directed in paragraph

VALVES

a. General. When checking and/or adjusting

valve clearance, it is necessary to remove the

crankcase breather adapter and the cylinder head

covers.

b. Removal of Components before Valve Ad-

justment. Remove the crankcase breather adap-

ter and the front cylinder head cover following

instructions in figure 62. The rear cover is re-

moved in the same manner as the front cover.

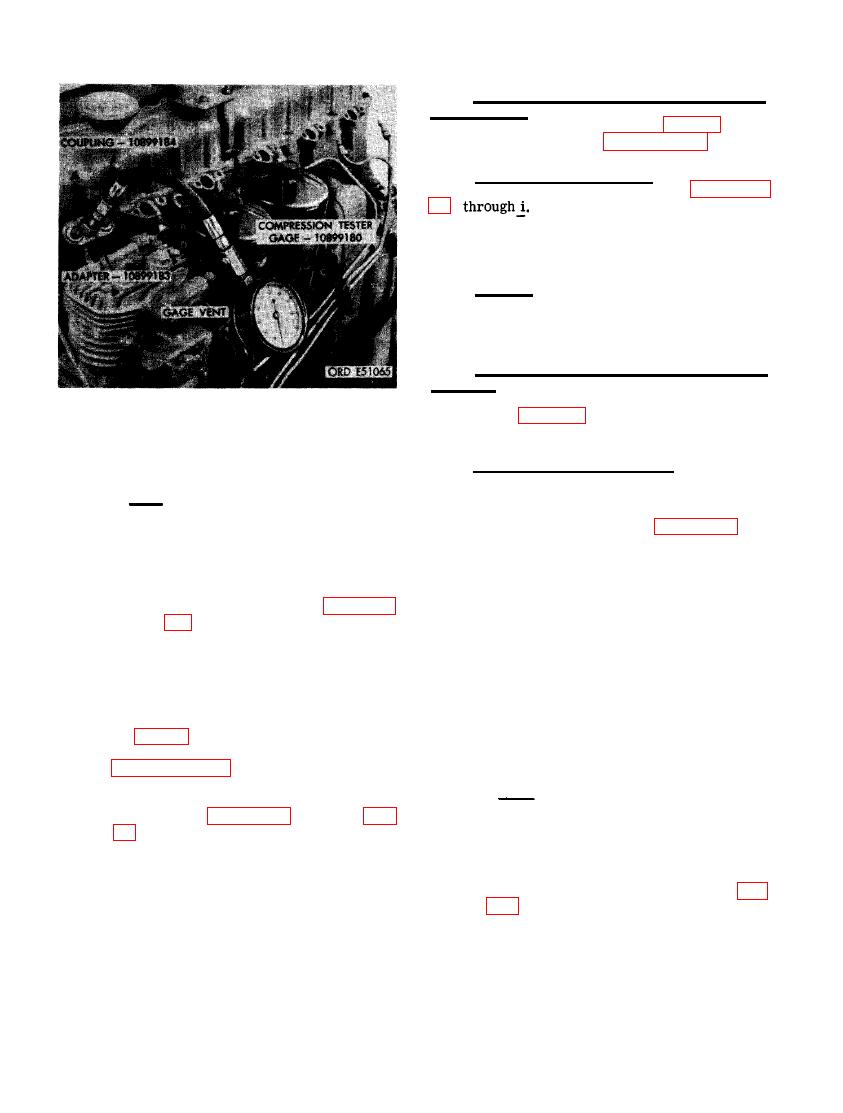

PRESSION USING COMPRESSION TESTER

GAGE -10899180, COUPLING -10899184,

c. Valve Clearance Adjustment.

AND ADAPTER - 10899183.

Note. Before checking or adjusting valve

Note. Compression pressure readings

clearance both valves must be closed on the

between cylinders Should not vary more

cylinder being checked. Refer to figure 183 and

than 25 psi ana pressure should not

follow the sequence of instructions to adjust in-

fall below 475 psi. Low compression

take and exhaust valve clearance. Valve clear-

on one or more cylinders causes

ance must be checked and set when the tappet

starting difficulty and poor engine per-

is on the base circle of the camshaft.

formance. When compression is low on

one or more cylinders, refer to para-

graph 49 for troubleshooting engine

(1) Rotate the crankshaft clockwise as

assembly and for corrective action.

viewed at the fan end, until cylinder No.

1 intake valve rocker arm is in its open

(4) During the cylinder compression test

position (valve open). At this position

operation, check all fuel injector nozzle

cylinder No. 1 exhaust valve is closed

and holder assemblies for satisfactory

and tappet is on base circle of cam-

operation. Remove fuel return tee (step

shaft. Clearance adjustment should be

A, fig. 150) and test fuel injector nozzle

made at this point.

and holder assemblies as. directed in

paragraph 83c and d l

Note. In each cylinder the valve to the

(5) Install fuel return tee in nozzle assem-

fan end is the intake valve, and the

bly. Refer to figures 148 and 149 (par.

valve to the flywheel end is the exhaust

valve.

tions and instructions to install the fuel

(2) Insert the correct size feeler gage be-

injector nozzle and holder assemblies.

tween the valve stem and the rocker

arm pad and check the' clearance (fig.

PRESSURE AND SPRAY PATTERN

ance is 0.015-inch (cold) and the cor-

rect exhaust valve clearance is 0.025 -

a. General. For instructional purposes in this

inch (cold). Loosen adjusting screw nut

section assumed that troubleshooting in-

and turn adjusting screw to obtain pro-

dicated defective nozzles and the nozzle and

per clearance. After adjustment is

holders have been removed from the engine.

made, tighten adjusting screw lock nut.

144

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |