|

|||

|

|

|||

|

Page Title:

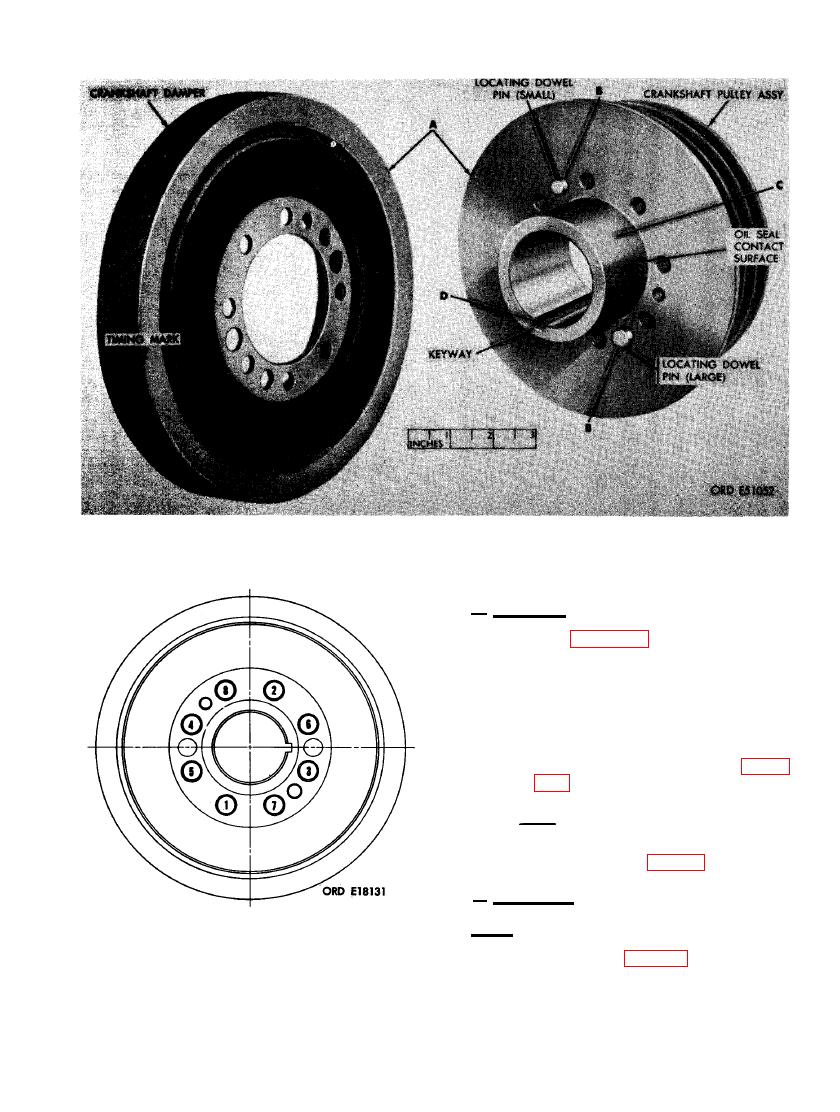

FIGURE 205. DISASSEMBLING, ASSEMBLING, AND INSPECTING CRANKSHAFT DAMPER AND PULLEY ASSEMBLY. |

|

||

| ||||||||||

|

|

SHAFT DAMPER AND PULLEY ASSEMBLY.

d. Assembly.

(1) Refer to figures 204 and 205 and reverse

the sequence of illustrations and in-

structions to assemble the crankshaft

damper and pulley assembly.

(2) Tighten the eight cap screws securing

the crankshaft damper to the pulley

assembly to a torque of 300 pound inches

following the sequence shown in fig-

ure 206.

Note. After once torquing the cap

screws to 300 pound inches, they again

must be retorqued to 360 pound inches

in proper sequence (fig. 206).

e. Installation.

Note. Before installing crankshaft damper

and pulley assembly on crankshaft, coat lip of

crankshaft front oil seal (fig. 207) and sealing

surface on pulley with lubricating oil to prevent

CRANKSHAFT DAMPER AND PULLEY

damage to oil seal lip when pulley is. installed.

ASSEMBLY ATTACHING SCREWS.

135

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |