|

|||

|

|

|||

|

Page Title:

Overhaul of Piston Oiler Nozzle Assembly |

|

||

| ||||||||||

|

|

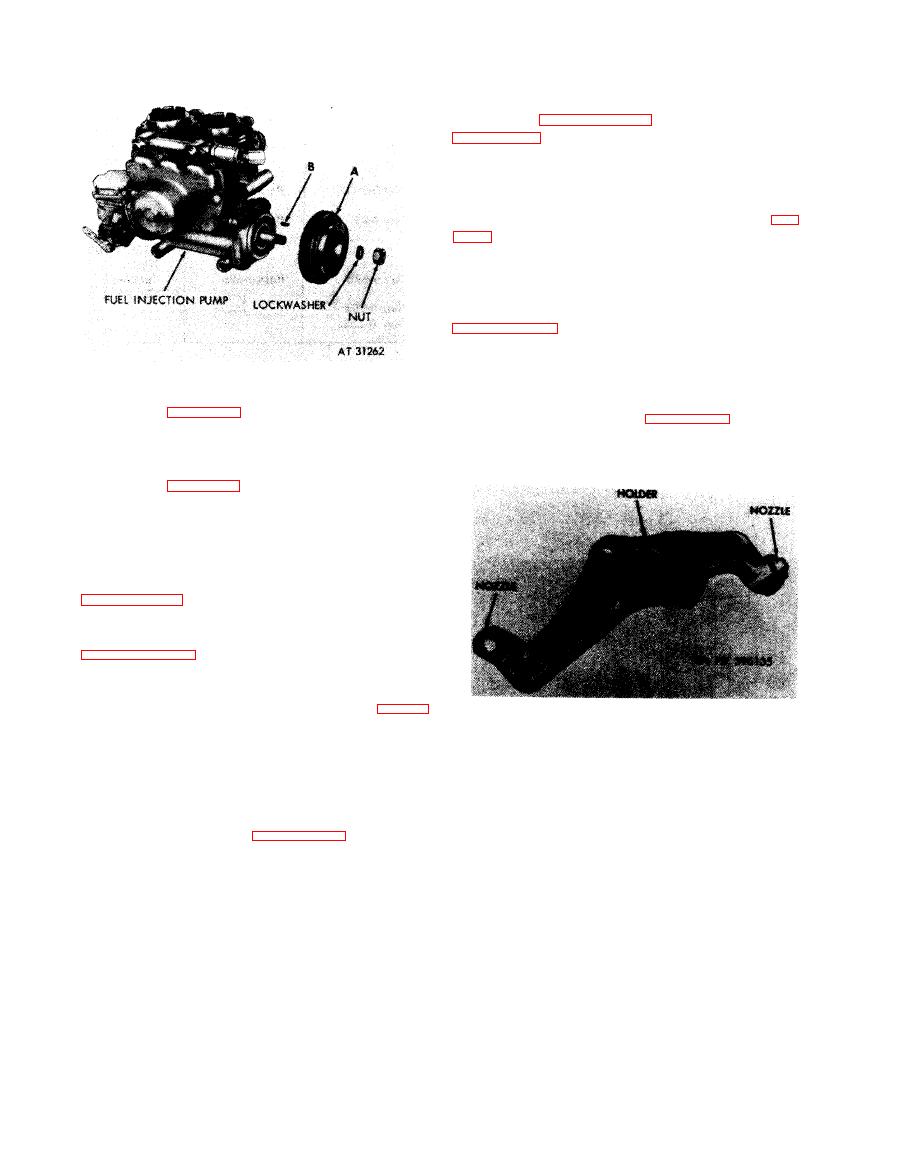

6-68.

Rebuild of Fuel Injector

Nozzle

and

Holder Assembly

Refer

to

through

4-24

and

figures 4-163 through 4-165 for rebuild of the

fuel

injector

nozzle

and

holder

assembly.

Overhaul of

Piston

Oiler

Nozzle

Assembly

cleaned without disassembly. To remove nozzles,

position holder in a soft-jawed vise and remove

nozzles.

b. Cleaning, Inspection, and Repair. Refer to

paragraphs 6-2 through 6-4. Make sure oil

passages in holder and oil holes in nozzles are

clean and free of obstruction. Replace nozzles

and holders as necessary, when oil passages and

Disassemble

holes cannot be cleaned of obstructions.

1. Refer to figure 4-60 and 4-62 to remove diaphragm

coupler (A) from injection pump.

the nozzle in the holder if removed. Stake nozzles

2. Remove Woodruff key (B) from pump shaft.

on three flats, 120 degrees apart.

Assemble

1. Position Woodruff key (B) in pump shaft.

2. Refer to figure 4-64 to install diaphragm coupler (A)

on fuel injection pump.

6-253. Disassembling

or assembling

fuel injection pump

drive

diaphragm

coupler.

b. Cleaning, Inspection, and Repair. Refer to

through

6-4,

and

(1)

and

(2),

below.

Drive

splined

coupler.

(1)

Refer

to

(7).

(2) Drive diaphragm coupler. W h e n

cleaning, Diaphragm must not be immersed in

fluids or cleaners. Inspect diaphragm (10, fig. B-

16) for cracks, scratches, or mars on rims or

holder

assembly.

diaphragms.

Inspect

diaphragm

pack

and

flange

coupler (12) keyways for wear or mutilation. If

diaphragm pack is cracked, do not attempt to

repair by welding. Replace unserviceable parts

by

salvage

or

replace

coupler

assembly.

6-216

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |