|

|||

|

|

|||

|

Page Title:

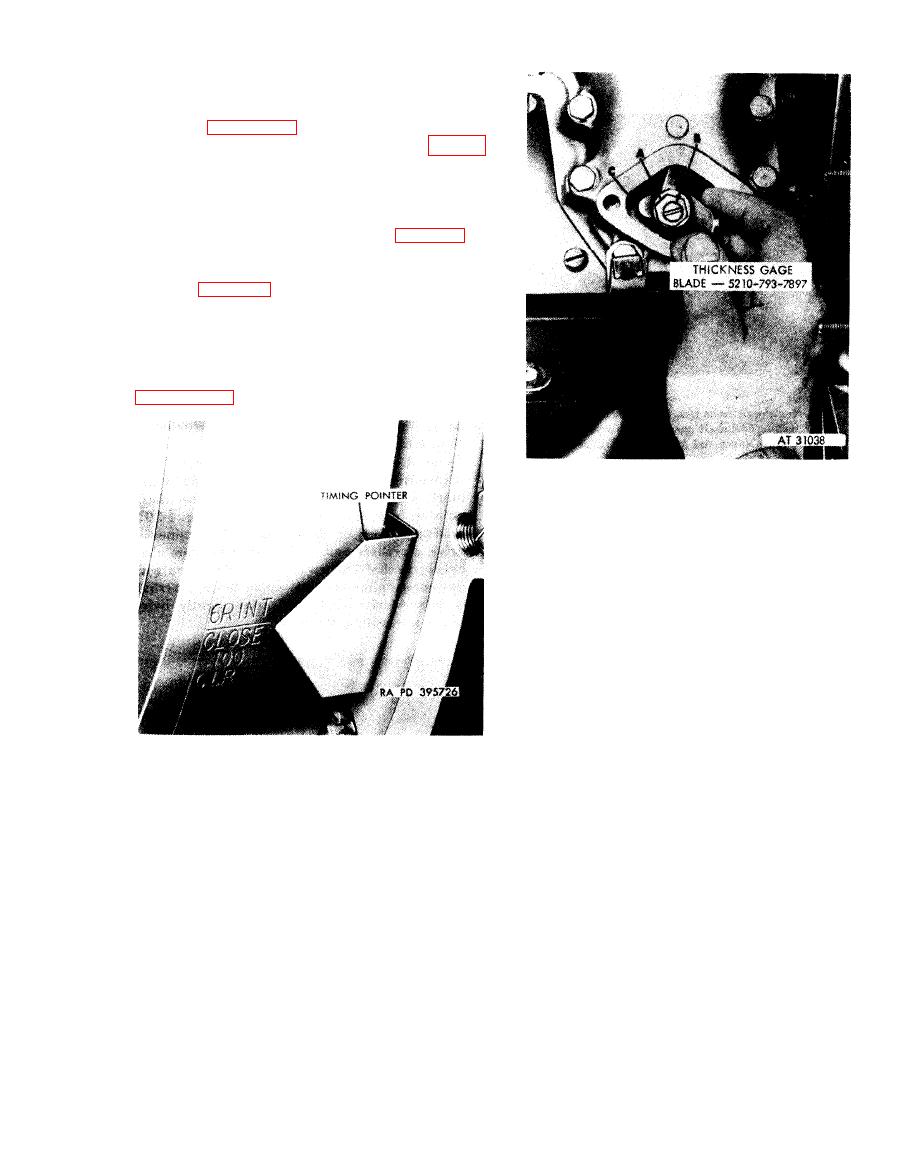

Figure 4-196. Flywheel timing marks a lined with pointer for valve timing-right bank of cylinders. |

|

||

| ||||||||||

|

|

b. Positioning Camshaft. Turn engine using

splined wrench - 5120-793-7895

until

valve

rocker arm roller is on base circle of camshaft as

shown in figure 4-73. Set number 6R and 6L

i n t a k e valve clearance to 0.100 inch (fig. 4-

197).

c. Checking Valve Timing. Turn flywheel

counterclockwise, viewed from rear, until pad on

valve adjusting screw is just free of the valve

stem (intake valve has just closed) (fig. 4-195).

In this position the fly-wheel mark "6R INT

CLOSE 0.100 CLR" should be alined with

pointer (fig. 4-196). If flywheel marks are not

alined with pointer within inch at the time the

adjusting screw pad becomes free of valve stem it

will be necessary to remove camshaft drive shaft

and reset valve timing. Valve timing may be reset

following the instructions that accompany

1. Loosen timing adjusting screw lock nut (A).

2. Turn valve adjusting screw (B) and set valve

clearance to 0.100 inch.

3. Gage (C) must move through clearance with a slight

drag. Tighten lock nut after setting clearance. Check

clearance to make certain setting has not changed.

for cylinder 6R using thickness gage

blade-5120-793-7897.

Figure 4-196. Flywheel timing marks a lined

with pointer for valve timing-right bank

of cylinders.

4-101

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |