|

|||

|

|

|||

|

Page Title:

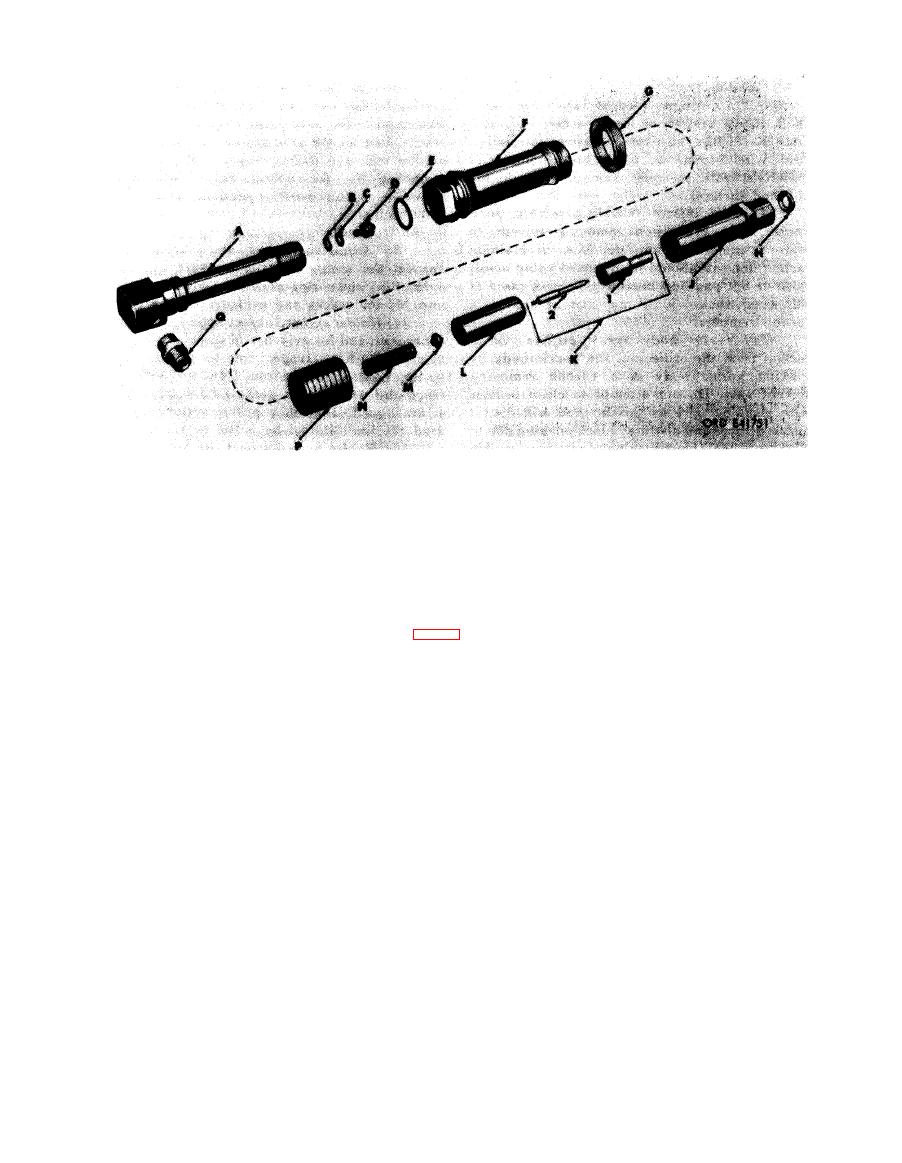

Figure 4-170. Disassembling or assembling fuel injector nozzle components. |

|

||

| ||||||||||

|

|

correct gage pressure reading on the nozzle tester

Disassemble

1. Remove fuel injector nozzle assembly (K), with nozzle

may require various combinations of spacers

body (K-1) and nozzle valve (K-2) from valve stop

available in shim set -5365-235-1941. Although

spacer (L).

each nozzle assembly pressure reading may vary,

2. Remove valve stop spacer (L) and nozzle opening

e x p e r i e n c e will indicate the approximate spacer

pressure adjusting spring (N) with spring upper and

thickness or combination of spacer thickness

lower seats (D and M) from holder body (A). Do not

remove the spring adjusting upper and lower spacers ( B

required to make up pressure differences. The

and C) from spring upper seat (D) unless ajustment of

n o z z l e assembly must be completely assembled,

the nozzle opening pressure is necessary during testing

torque tightened and checked again on the

of the fuel injector nozzle and holder assembly ( para 4-

nozzle tester to assure proper spacer combination

17).

a n d pressure reading. This procedure may have

3. Remove and discard preformed packing (E) from

holder body (A).

t o be repeated several times before achieving a

4. Disassemble fuel injector nozzle assembly (K) by

s a t i s f a c t o r y reading.

removing nozzle body (K-1). It may be necessary to

1. Assemble nozzle valve (K-2) in nozzle body (K-1) to

soak the nozzle assembly in carbon removing solvent to

form fuel injector nozzle assembly.

aid in disassembly. It may be necessary to tap nozzle

2. Install a new preformed packing (E) in holder body

body downward on the edge of a wooden bench or other

(A).

similarly soft surface to remove valve.

3. Install spring upper seat (D), with spring adjusting

Note. The nozzle body and nozzle valve are

upper and lower spacers (D and M) in end of nozzle

f i t t e d individually during manufacture to form a

opening pressure adjusting spring (N). Install spring

lower seat (M) in opposite end of spring (N) and install

mated assembly. Individual parts are not in-

assembled spring and valve stop spacer (L) in holder

t e r c h a n g e a b l e . Therefore, extreme care must be

body (A).

taken during the cleaning, inspection, and repair

4. Install fuel injector nozzle assembly (K-1 and K-2) in

o p e r a t i o n s to keep these parts mated.

valve stop spacer (L).

Assemble

Note. During

assembly,

the

addition

or

removal of spring adjusting spacers to obtain the

Figure 4-170. Disassembling or assembling fuel injector nozzle components.

4-85

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |