|

|||

|

|

|||

|

Page Title:

Troubleshooting Lubricating System |

|

||

| ||||||||||

|

|

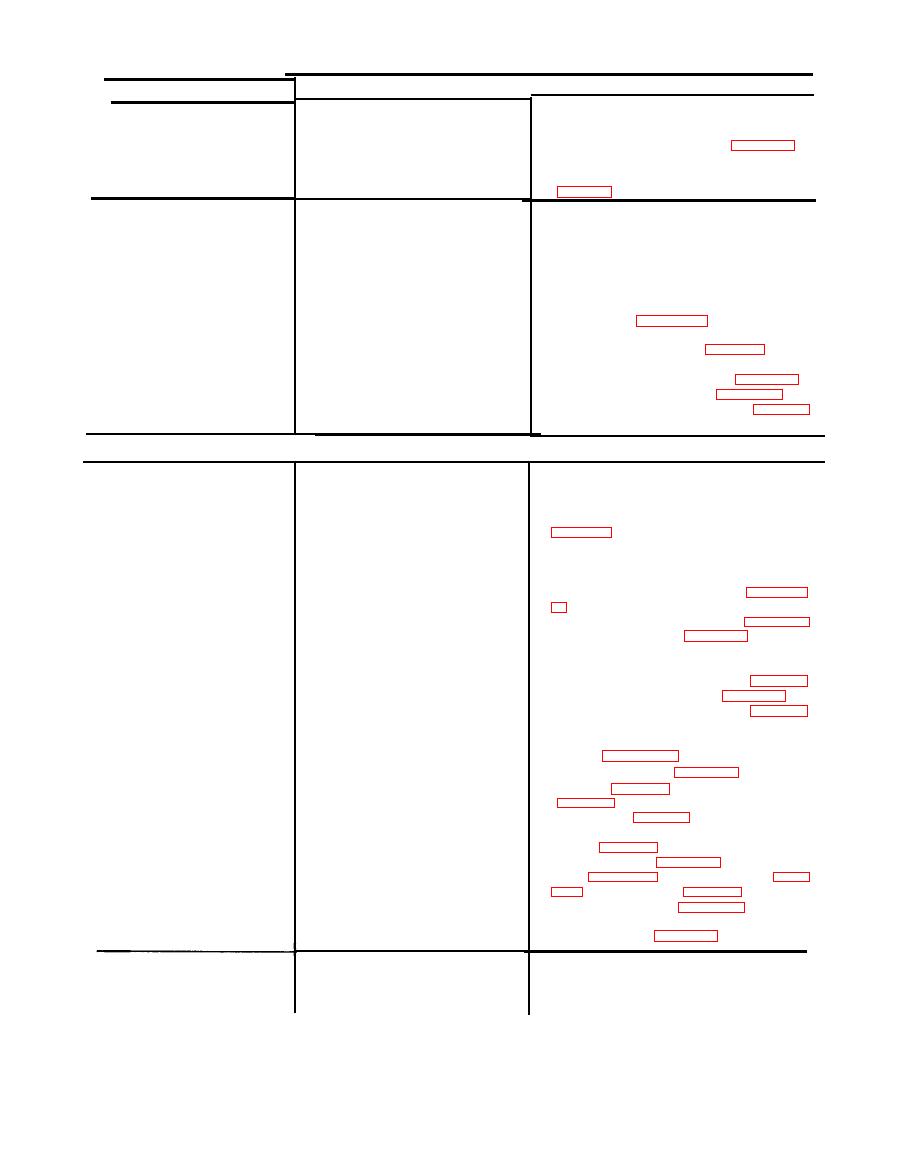

Corrective Action

Malfunction

Probable Cause

e. Improperly adjusted fuel injection

e. Adjust fuel injection pump. Refer to TM 9-

pump.

2910-212-34 for procedures.

f . Remove fuel injection pump (table 4-1).

f . Fuel bleeder valve in injection

Refer to TM 9-2910-212-34 for overhaul

pump not functioning properly.

p r o c e d u r e s . Install fuel injection pump

a. Adjust fuel injection pump. Refer to TM 9-

a . F u e l injection pump improperly

4. Excessive exhaust smoke.

2910-212-34 for procedures.

a d j u s t e d causing excessive fuel

delivery.

b. F u e l injector nozzle and holder

b . Refer to item 2c, above, for corrective

functioning

assemblies

not

action.

properly. Nozzles dripping or

nozzle holder spring broken.

c. T u r b o s u p e r c h a r g e r f a i l e d o r

c.

Refer

to

above,

for

restricted induction system.

troubleshooting procedures.

d. Fuel injection pump not properly

d. Time fuel injection pump (table 4-1). Also

timed.

refer to TM 9-2910-212-34.

e. Remove cylinders and pistons (table 5-9)

e. Worn or scored pistons, cylinder,

or rings.

and replace defective parts (tables 6-12 and

6-14). Install pistons and cylinders (table 5-

9).

Troubleshooting

Lubricating

System

a. Drain oil pan and refill with proper grade

1. Low engine oil pressure.

a. Improper grade oil for prevailing

o i l for prevailing temperature. Refer to

temperature.

p e r t i n e n t vehicle Technical Manual, Ap

b. Check engine idle speed and reset to 700 to

b. Engine idle speed too low.

7 5 0 rpm.

c. Fill oil pan to proper level. Refer to per-

c. Insufficient oil in oil pan.

tinent vehicle Technical Manual, Appendix

d. Remove oil pressure sending unit (table 5-

d. Engine oil pressure sending unit

10). Install new unit (table 5-10).

not functioning properly.

e. Refer to 4, below, for corrective action.

H i g h engine oil temperature or

e.

diluted oil.

f. Remove oil pressure regulator valve (table 4-

f . Oil pressure regulator valve not

2 ) . Replace damaged parts (para 6-38d).

operating properly.

Install oil pressure regulator valve (table 4-

2).

g. Refer to pertinent vehicle Technical

g. Oil filters partially obstructed.

Manual, Appendix A for service procedures.

h. Crankcase oil passages obstructed.

h. Disassemble engine (chapter 5). Clean oil

passages (para 6-9c). Assemble engine

(chapter 7).

j. Oil pump pickup tube screen

j . Remove oil pan (table 4-5). Clean ob-

obstructed.

structions from pickup tube screen. Install

oil pan, (table 4-5).

not

functioning

k. Oil pump

k . Remove oil pan (table 4-5). Remove oil

properly.

pump (table 5-10). Rebuild oil pump (table

l. Engine bearings worn.

l. Disassemble engine (chapter 5). Replace

worn bearings and necessary parts.

Assemble engine (chapter 7).

a. O i l p r e s s u r e s e n d i n g u n i t n o t

a. Refer to 1d, above, for corrective action.

2. High engine oil pressure.

functioning properly.

b. Oil pressure regulator valve not

b. Refer to 1f, above, for corrective action.

functioning properly.

3-9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |