|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-270-34

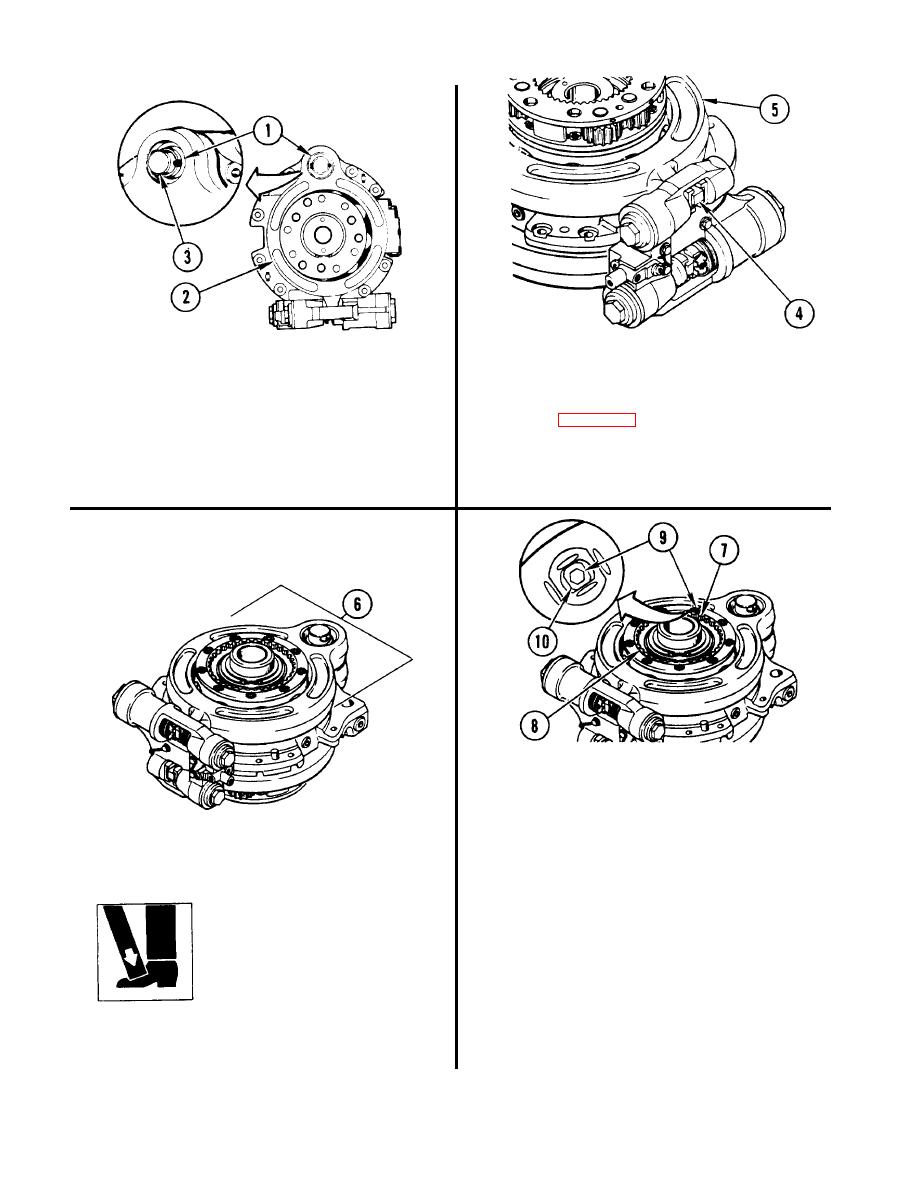

11. INSPECT TANG (4) ON OUTER

RACE (5).

10. CHECK PINTLE PIVOT POINT (1) ON

OUTER RACE (2).

a. Inspect tang (4) for damage.

See page 2-5.

Rock race (2) back and forth.

a.

b. If tang (4) is not damaged, go to

b. If race (2) rocks freely, go to step 11.

step 12. If tang is damaged, go to

If race binds on pintle pin (3), go

step 39.

to step 39.

13. INSPECT SPLINED TEETH (7) ON

INNER COUPLING (8).

a. If teeth (7) are not damaged, go to

step 14. If teeth are damaged, go

to step 39.

CAUTION

WARNING

Tools must not be used to inspect tightness

Hydraulic assembly is heavy

of parts. Staking of bushings can be damaged.

and could fall and injure you or

other personnel.

14. INSPECT NINE SCREWS (9) AND

S T A K E D BUSHINGS (10).

a. If screws (9) and bushings (10) are

tight, go to step 15. If screws or

12. REPAIRER AND HELPER TURN

bushings are loose or missing, go to

H Y D R A U L I C ASSEMBLY SO THAT

step 39.

INNER HYDRAULIC UNIT (6) FACES UP.

4-372

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |