|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 9-2520-270-34

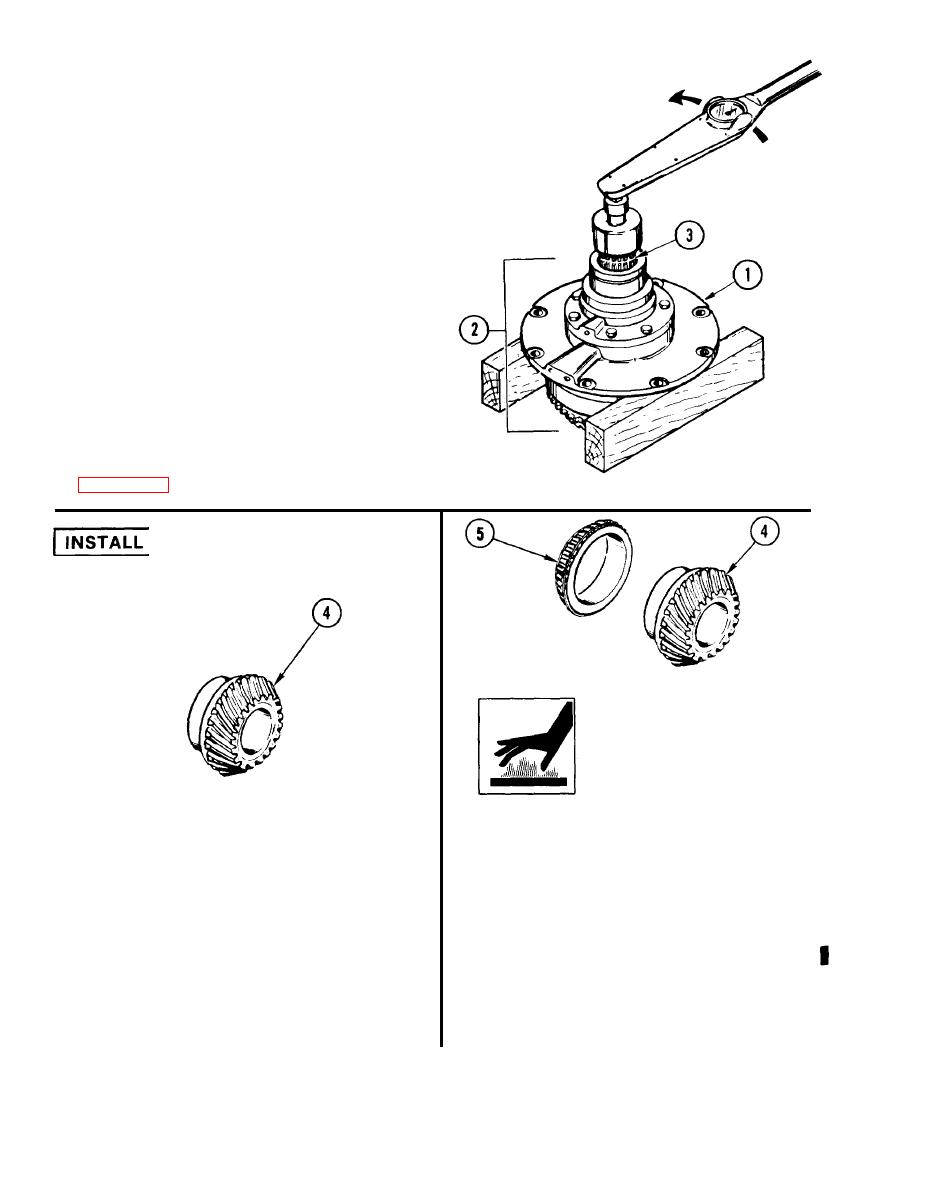

43. PLACE BEARING HOUSING ASSEM-

BLY (1) ON TWO WOOD BLOCKS.

a. Put blocks under outside edge of

housing assembly (1).

44. CHECK TURNING TORQUE OF

INPUT BEVEL ASSEMBLY (2).

a. (H) Hold housing assembly (1).

b. Using 3/8-inch drive torque wrench

with adapter and drag wrench, slowly

and smoothly turn input gearshaft (3)

completely around and measure turning

torque.

c. If turning torque is not 15-20 in-lb

(17-23 cmkg),

go to step 45. If

turning torque is 15-20 in-lb

(17-23 cmkg), go to step 46.

45. REPAIR INPUT BEVEL ASSEMBLY,

WARNING

Do not handle hot or cold

parts without protective

gloves. Personnel can be

injured.

47. INSTALL CONE AND ROLLERS (5)

ON PINION (4).

a.

Using dry ice, cool pinion (4) for

approximately two hours.

NOTE

b.

Using oven, heat cone and rollers (5)

Bevel gear and pinion are a matched set and

to 270 -300 F (132 -149 C) .

must be replaced together. Serial numbers of

Wearing gloves, slide cone and

c.

gear set must match.

rollers (5), wide end first, onto

pinion (4), fully seating cone and

46. INSTALL PINION

(4).

rollers against pinion shoulder.

If pinion (4) was removed, go to

a.

d.

Let parts return to room temperature.

step 47. If not, go to step 48.

Change 1

4-102

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |