|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

NOTE

5-29. Cleaning

Do not stretch seal any more than is

Refer to paragraph 5-2 for cleaning recom-

absolutely necessary.

mendations.

(3) Install seal expander (fig. 5-78) into inner

groove of piston.

Refer to paragraph 5-3 for general inspection and

NOTE

repair recommendations. Repair and overhaul

Both ends of seal expander must be as

(rebuild) points of measurement for fits, clearances,

shown in figure 5-78 when it is coiled. Ends

and wear limits are indicated by small letters in

must curve away from seal ring so that they

will not gouge seal.

for general wear limits information. Do not scuff,

(4) Starting at a point opposite open ends of

cut, tear, or distort Teflon seal ring.

expander, install seal into groove.

(5) Center piston in piston housing, and push

5-31. Assembly

evenly into piston bore. The broader, flat side of

piston goes toward housing bore.

NOTE

(6) Install 12 springs (34) in housing assembly

All items not covered in a and b below or in

(25).

separate rebuild sections, are installed as

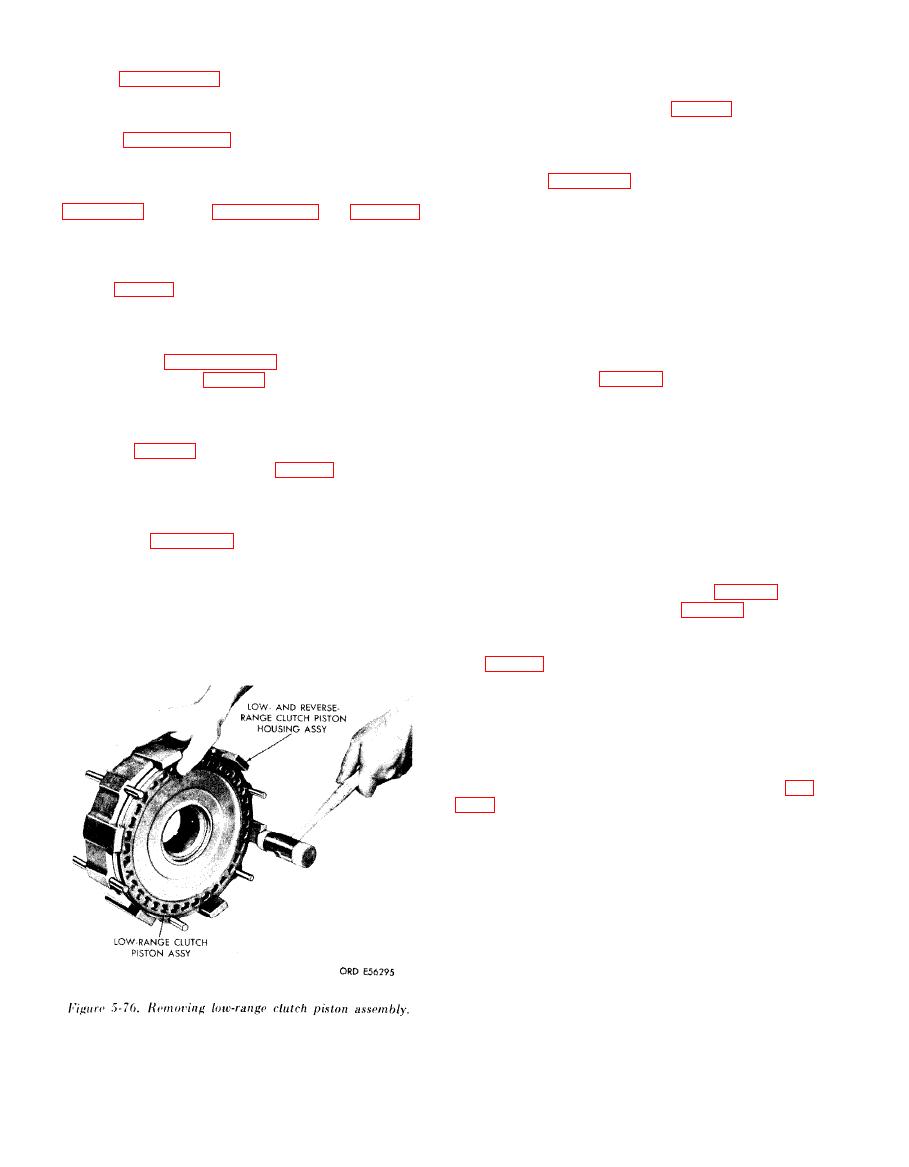

b . Low-and Reverse-Range Clutch Piston

outlined in paragraph 5-58, assembly steps

11 through 20 (fig. 5-93 through 5-102).

(1) If necessary to replace any of six anchor

No overhaul (rebuild) of such components

pins (54), press pin(s) into housing (52) until end

is required or recommended.

of pin with hole projects 1.85 inches from flat side

a. Intermdiate-range Clutch Piston Housing

of housing. Hole in end of pin must point ap-

proximately toward center of housing.

(1) Install seal expander (fig. 5-77) into outer

(2) If necessary to replace two anchor pins

groove in piston.

(53), press them in until end of pin(s) projects 0.62

NOTE

inch from flat side of housing.

Both ends of seal expander must be as

(3) Install reverse-range clutch piston hook-

shown in figure 5-77 when it is coiled. Ends

type seal ring (55) and low-range clutch piston

must curve away from seal ring so that they

hook-type seal ring (50).

will not gouge seal.

(4) Install seal expander (2, fig. 5-75) on

(2) Starting at a point opposite open ends of

reverse-range clutch piston (3, fig. 5-75) in same

expander, install seal ring in groove. It will be

manner as instructed in a (1) above.

necessary to stretch outer seals slightly to get them

(5) Install reverse-range clutch piston seal ring

into the groove.

(1 , fig. 5-75) in same manner as instructed in a (2)

above.

(6) Install seal expander (48) on low-range

clutch piston (47) in same manner as instructed in

a (l) above.

(7) Install low-range clutch piston seal ring

(49) in same manner as instructed in a (2) above.

(8) Center reverse-range clutch piston (3, fig.

respective bores in housing (52), and push each

evenly into bores in housing. The broader, flat sides

of pistons go toward housing bores.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |