|

|||

|

|

|||

|

Page Title:

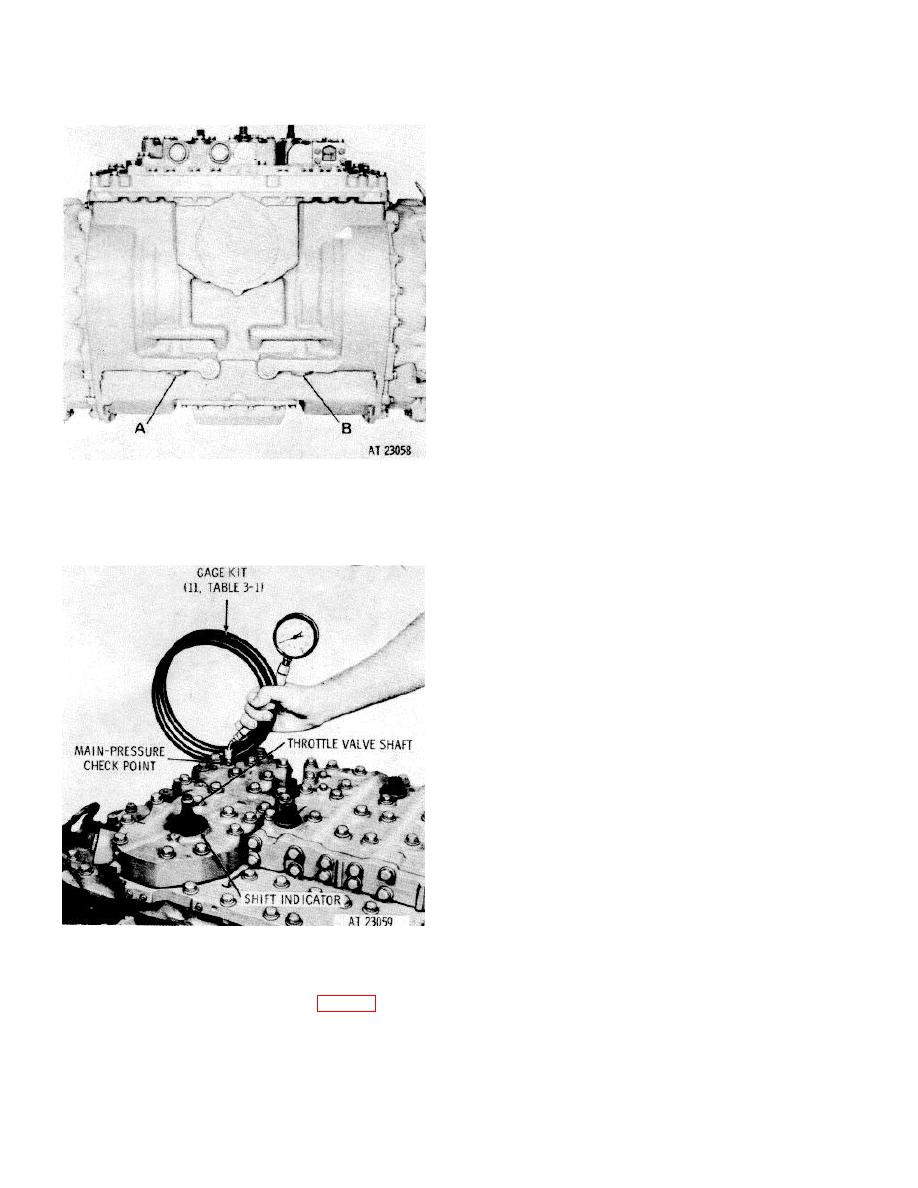

Figure 9-3. Transmission oil pressure check points-rear |

|

||

| ||||||||||

|

|

TM 9-2520-249-34& P

(2) In all tests, the transmision sump

temperature should be normal (180 to 2200F).

Connect the pressure gage(s) to the check point(s)

indicated for the test being made.

(3) Reduce the speed of the transmission

input to engine idle speed before engaging the desired

range. Then slowly increase speed to the rpm desired.

Record the pressure reading for each test.

(4) Do not attempt to remove or install the

pressure gage(s) while the transmission is operating.

Tightly reinstall the plugs immediately upon removing

the gage(s)

(5) When making the tests for steer clutch

pressure, move the steer control from center to full steer

slowly while observing the pressure rise. Pressure

should be maximum at full-steer position.

(6) In test for lockup engagement with unit in

third gear, increase speed slowly until lockup apply

pressure registers. Record output speed which registers

at that time.

(7) In tests for lockup release with unit in third

A-Left brake coolant

gear, first increase the input speed to above the point

B-Right brake coolant

where lockup occurs. Observe lockup clutch apply

pressure while slowly reducing the speed until lockup

Figure 9-3. Transmission oil pressure check points-rear

pressure drops quickly. When pressure drops quickly,

view.

record the output speed.

(8) During all tests observe the left and right

transmission output rotation. Rotation should be as

outlined in e, below.

e. Rotation of Transmission Outputs.

(1) In all forward and reverse gears the

transmission outputs will tend to rotate even at engine

idle speeds. A light application of the brake will stop

such rotation when the transmission is functioning

properly.

(2) In all forward gears, the transmission

output should rotate clockwise as viewed from the right

side of the transmission when no steer is applied.

(3) In reverse gears, the transmission output

should rotate counterclockwise as viewed from the right

side of the transmission when no steer is applied.

(4) In first gear, during normal or pivot steer,

and in second and third gears during pivot steer, the

output at the side toward which the turn is made rotates

counterclockwise. The output at the opposite side

rotates clockwise. Both rotations are as viewed from the

right side of the transmission.

(5) In second, third and fourth gears during

normal steer, and in fourth gear during pivot steer, both

Figure 9-4. Checking transmission main pressure.

outputs rotate clockwise (as viewed from the right side

of the transmission). The output at the side toward

d. Functional Tests.

which the turn is made rotates slower than the output on

(1) The test data log sheet (fig. 9-1) can be

the opposite side.

used as a guide for making functional tests, as well as

providing spaces to record actual test results. In

addition, the normal pressures are included for

comparison with test results.

9-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |