|

|||

|

|

|||

|

Page Title:

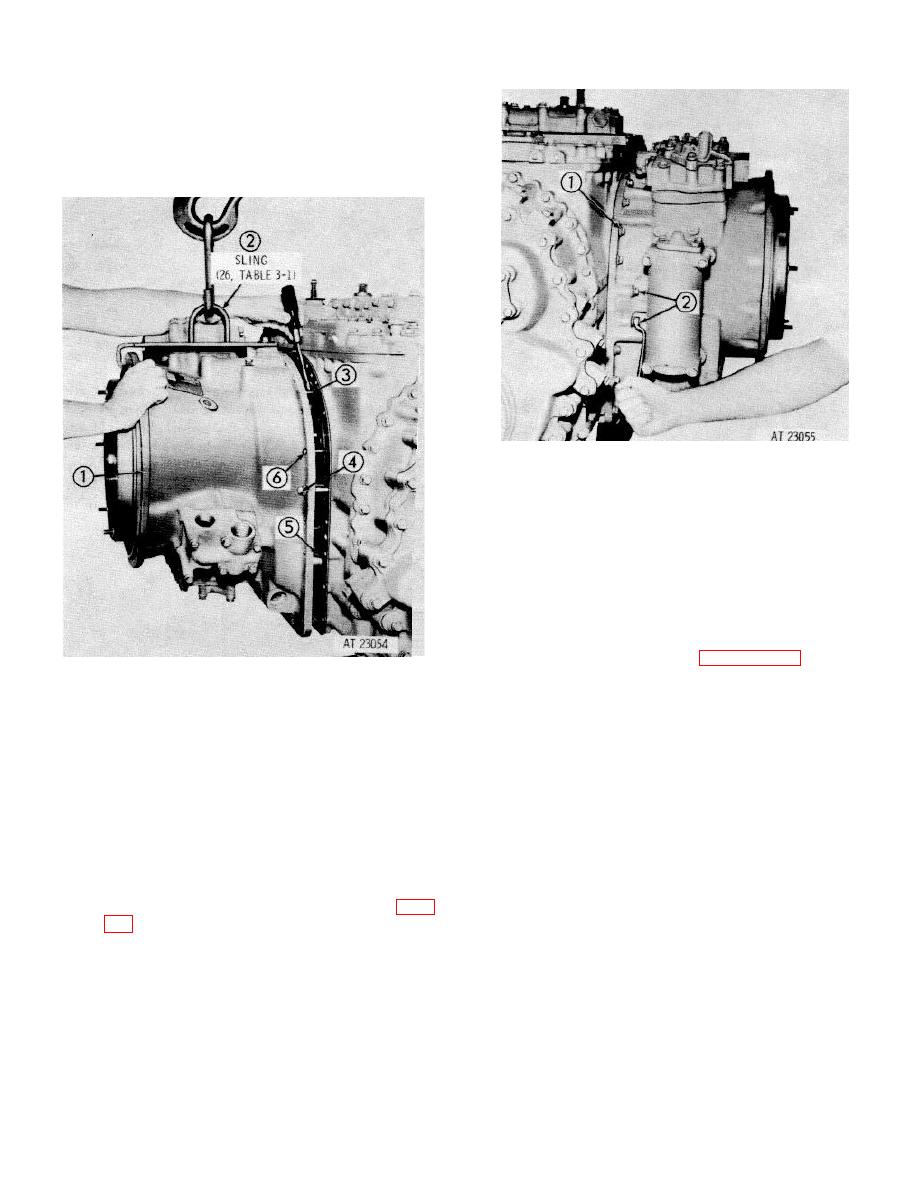

Position converter housing assembly |

|

||

| ||||||||||

|

|

TM 9-2520-249-34& P

NOTE

Be careful that low-range clutch disks (3),

springs (2) and spring pins (1) do not fall

out of the housing.

The low-range

planetary carrier assembly splines (5) must

engage bevel gear carrier splines (6).

125 Install twenty-one /8- 16 x 1 5/8-inch bolts (1).

two 3/8-16 x 2 3/4-inch bolts (2), 23 plain

washers and 23 lockwashers. Install one 3/8-16

x 3 1/4-inch bolt at the top of the converter

housing, and install one plain washer and one

lockwasher. Tighten 24 bolts to 27 to 32 pound

feet torque. Install oil filler and level indicator

kit (62, foldout 101.)

NOTE

To establish the oil level in the power train

following overhaul. refer to paragraph 9-4b (6)

124 Position

converter

housing

assembly

(1)carefully on guide bolts (6), being careful not

to damage oil suction tube (5). Install two 3/8-

16 x 2 3/4-inch bolts (4), 180 degrees to each

other, and, while making repeated checks to

ensure that the clutch plates are in position and

the springs and pins (3) are perpendicular to the

piston face, draw the converter housing toward

the bevel gear housing. Install two 3/8-16 x 1

5/8-inch bolts, two plain washers and two

lockwashers, 180 degrees to each other and

draw the converter up completely to the bevel

gear housing. Remove the two guide bolts and

the two draw bolts. Remove sling (2), (26, table

8-42

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |